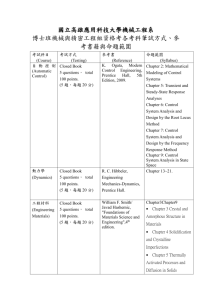

Manufacturing Engineering (3 Credits) 制造工程

advertisement

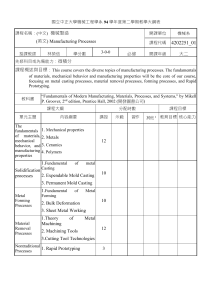

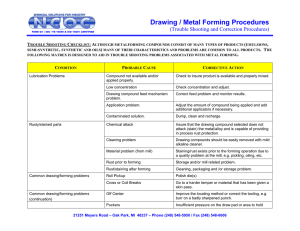

Manufacturing Engineering (3 Credits) 制造工程 Instructor Mike MUNRO Mech and Ind Eng Dept, University of Toronto (munro@mie.utoronto.ca) Description Production Fundamentals: Metal casting; metal forming - rolling, forging, extrusion and drawing, and sheet-metal forming; plastic/ceramic/glass forming; metal removal - turning, drilling/ boring/reaming, milling, and grinding; non-traditional machining - ECM, EDM and laser cutting; welding; surface treatment; metrology. Environmental issues in manufacturing processes, recycling of materials. Automation Fundamentals: Automation in material processing and handling - NC, robotics and automatically-guided vehicles; flexible manufacturing - group technology, cellular manufacturing and FMS; and computer-aided design - geometric modelling, computer graphics, concurrent engineering and rapid prototyping. Offering 2013 Summer Semester Audience Year 2 and Year 3 Undergraduate Students Prerequisites Students should have taken introductory courses in the properties of materials and technical drawing (although sufficient details of technical drawing will be reviewed in the lab sessions). Classroom Room 2, Teaching Bldg. No. XX, Peking University Frequency July 1–31, 2013: 8-10 AM (Lectures), 4-5/6 PM (Labs & Tutorials), M-F Objectives 1. Become familiar with manufacturing processes. 2. Be able to discuss the applicability of processes for mechanical components using detailed, organized technical arguments. 3. Be able to identify actual manufacturing processes used to produce mechanical components. 4. Draw manufacturing set-ups for specified components. 5. Understand the relationships between mechanical design, materials and manufacturing. Topics 1. 2. 3. 4. 5. 6. 7. Manufacturing processes for metallic materials (50%) (materials for mid-term). Manufacturing processes for polymeric materials (20%). Manufacturing processes for ceramic materials (1%). Manufacturing processes for fibre composite materials (15%). Non-traditional machining (2%). Recycling of materials (2%). Automation fundamentals (10%). Reference Manufacturing Engineering and Technology, S. Kalpakjian and S. Schmid, 6th ed. (Course notes based on the reference will be provided in the softcopy form). Project There will be a group project (probably three students per group) to develop a new design/ Overview associated manufacturing process(es) for a component that will be provided to each group. Past components have included bicycle bells, pliers and aviation snips. Grading Midterm Final Project Assignments Total 20% 45% 10% 25% 100%