Instructor

advertisement

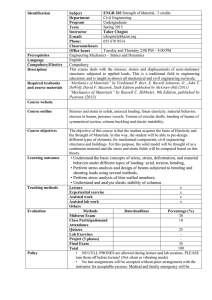

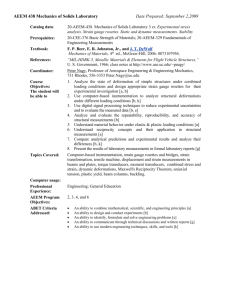

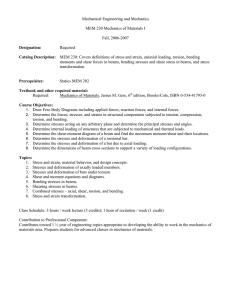

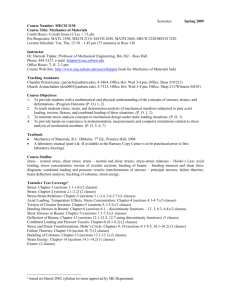

Mechanics of Solids (3 Credits) 固体力学 Instructor Shaker A. Meguid Mech and Ind Eng Dept, University of Toronto (meguid@mie.utoronto.ca) Description This is an introductory course in solid mechanics. It consists of studying the behaviour of structural members and machine components under applied loading and applying that knowledge to analyze real engineering problems. The applied loads can be axial or transverse forces, twisting torques, bending moments and combinations thereof. These loads, which are transmitted through structural members and machine components via internal stresses, lead to deformations/deflections of these components. Both elastic and elasto-plastic deformations are studied. The course further considers complex stress system and stress transformation under plane loading conditions and emphasizes the use of failure criteria in the design process. Both strength and rigidity calculations are considered through out the course and concepts are examined using assignments and experimental mechanics. Offering 2013 Summer Semester Audience Year 2 Undergraduate Students Classroom Room 2, Teaching Bldg. No. XX, Peking University Frequency July 1–31, 2013: 10-12 PM, M-F Objectives Topics Additional Info To develop skills in treating new structures involving mechanical loading, identifying the critical parameters that govern the behaviour of the structure, and making engineering assumptions that would ultimately lead to realistic stress and displacement solutions for the structure. Students will learn to derive and use a comprehensive list of stress analysis formulas, to clearly document solution procedures, and assess the realism of their answers. 1. 2. 3. 4. 5. 6. Project Project Deadlines Grading Total: 100% 7. Principal Stresses and Principal Strains 8. Yield and Failure Criteria 9. Circular and Spherical Pressure Vessels 10. Deflection of Beams 11. Statically Indeterminate Structures & Thermal Loading Extensive visual aids are typically used to demonstrate complex concepts and aid in visualizing these topics and the underlying concepts. The course is further supported by a number of projects that are revised annually. Examples of these projects include the failure analysis of: (a) (b) (c) (d) Textbook Axial loading of members Elasto-Plastic Torsion Torsion of Noncircular Sections Elasto-Plastic Bending of Beams Shearing Stresses in Beams Transformation of Stress and Strain States Dovetail regions in compressor disc assembly of GTEs, A stringer in the fuselage of a commercial airliner, A large marine gear as a result of overload, and Brittle fracture of a pressure vessel. Mechanics of Materials, F.B. Beer, R. Johnston & J.T. DeWolf, McGraw-Hill Engineering, 6th Ed, 2011. The project consists of synthesis, modelling and analysis of one of the above stated projects. Students are assigned these projects in the first lecture and are asked to validate their hypotheses by conducting finite element modeling, photoelastic stress analysis, strain gauge measurements, mechanical testing, and imaging of the fracture surfaces. Students are to work in teams of four assigned by the instructor. The work should be evenly divided and team members will in general receive the same project grade. All papers should provide a review of the current literature and discuss the results of their finite element model of the particular topic under review validated by photoelasticity and strain gauge experimental stress analysis. Each team will submit a written report not exceeding 10 pages. Literature Review: 1st Week Finite Element Model: 2nd Week Final: 40% Midterm: 20% Photoelasticity & Strain Gauges: 3rd Week Final Report: 4th Week Assignments: 10% Project: 30%