NCC508-00#1

advertisement

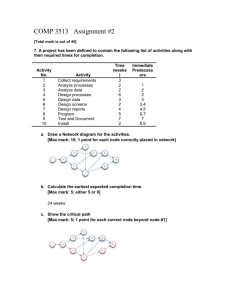

II. Operations Strategy and Process Choice 1. Operations Management and Competitive Advantages – – “An Efficiency Drive” “Case Study: Burger Time” 2. Process Types and The Product-Process Matrix 3. Case Discussion: Kristen’s Cookies 4. Process Flow Diagram and Gantt Chart 1 An Efficiency Drive • How critical is time for drive-through? • Is drive-through a good deal for the restaurants? • What are the efforts to save time? • Implications 2 Case Discussion: Burger Time • What are the major operational differences between McDonald’s and Burger King? • How do these differences relate to each company’s competitive strategies? • What implications do these differences have for the management of operations? 3 4 Competitive Advantages and Operations Management Competitive Advantages • Price – Cost • Quality – Customer service – Consistent quality • Time – Rapid, reliable delivery • Variety Operations Management • Match supply with demand • Quantitative methods and qualitative strategies to • ensure efficient use of resources • find the right balance between competing objectives • improve performance along multiple dimensions simultaneously 5 Performance Dimensions in Retail Banking • Quality: courteous services, consistency (reliability), accurate information (credibility), empathy, timely information (customer responsiveness), conformance, employee skill and knowledge • Time: delivery speed (waiting time), convenient services (access), on time delivery (account statements), handling customer complaints • Flexibility: a broad line of financial products, system responsiveness, new product introduction speed, rapid staff changes, customizations • Cost: cost effective back and front-office labor productivity, cost effective back-office technology innovations, transaction processing costs 6 The changing sources of competitive advantage • Low Cost & Scale Economies (< 1960s) • Focused Factories (mid 1960s) • Flexible Factories and Product variety (1970s) • Quality (1980s) • Time (late 1980s-1990s--> ) 7 Process types: Match Supply with Demand • Economics • Two options • Make supply after demand: Make to order (MTO) • Make supply before demand: Make to stock (MTS) • Matching supply with demand means 8 Process Types: Resource Types and Layout • Job Shop process – General purposed/flexible resources – Process focused layout: Jobs have flexible routing, go from one resource to another as needed – Wide variety of products, customized products • Batch process – Similar to JS, but with larger lot sizes, some EOS, more commonality in the resources required, still not cost effective to build a dedicated assembly line. • Discrete flow process – Product focused layout: Fixed (possibly automated) flow of products, tightly connected stages (WIP is automatically managed), specialized tasks – Heavily capitalized – High volume • Continuous flow process – Product focused layout – heavily capitalized – Product is a commodity – no discrete units, minimal variety, high volume 9 Matching Products and Processes Product Process Jumbled Flow. Process segments loosely linked. Low volume Low Standardization One of a kind Low volume Higher volume Many Products Few Major Products High volume High Standardization Commodity Products Scheduling, Materials Handling, Shifting Bottlenecks JOB SHOP (Commercial Printer, Ph.D program) Disconnected Line Flow/Jumbled Flow but a dominant flow exists. BATCH Worker Motivation, Balance, Maintaining Flexibility (Heavy Equipment, MBA program) DISCRETE FLOWS Connected Line Flow (assembly line) (Auto Assembly) CONTINUOUS FLOW Continuous, automated, rigid line flow. Process segments tightly linked. (Oil Refinery) Bidding, delivery, product design flexibility Quality & Product Differentiation, output volume flexibility Price Capital Investment for big chunk capacity, Technological Change, Vertical Integration Managerial Challenges 10 11 Process Flow Diagram: Kristen’s Cookies Mix Time 6 (minutes/dozen) Spoon 2 Set Bake oven 1 9 Cool Pack Pay 5 2 1 Capacity (dozen/minute, for orders of 1 dozen) Max batch 3d d Resources K K d d R, Oven Oven R R 12 13 Gantt Chart Mix and Spoon Bake Cool Pack Pay Kristen Room-mate Tray #1 Tray #2 Tray #3 Tray #4 5 10 15 20 25 30 35 40 45 50 14 15 2nd Stage FB Reactor CFB Preheater 1st Stage CFB Reactor ~ 110 m Inclined Bucket Elevator Briquetting Plant Process Gas Heat Exchanger Iron Ore Fines Process Gas Compressor Electrical Substation& Control Room Fired Gas Heaters HBI Product ~ 160 m 16 Pre-Heater Lock Hoppers 1st Reactor Discharge 2nd Reactor Flash heater Briquetting Pile of Iron ore fines Finished goods 17 Process Flow Diagram and Gantt Chart • Process Flow Diagram: Illustrates the flow of product or service from input to final output (stages). – Software (Visio et al.) • Gantt Chart: Illustrates the interplay between resources at all time – Important for scheduling and coordinating production – Software (Microsoft Project) 18 Today’s Takeaways 1. Operations management and competitive advantages 2. Process Types and The Product-Process Matrix – Process Types • • – Matching supply with demand: MTO vs. MTS Resource types and layout: job shop, batch, discrete flow, continuous flow The Product-Process Matrix: Diagonal 3. Case discussion: Kristen’s Cookies 4. Process Flow Diagram and Gantt Chart – – Flow Diagram: stages products flow through Gantt Chart: interplay of resources Operational Measures 19