Six Sigma - Gateway Engineering Education Coalition

advertisement

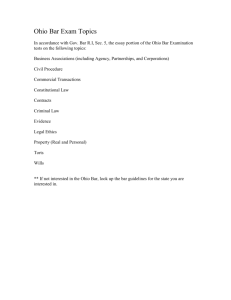

GATEWAY Six Sigma Department of Mechanical Engineering, The Ohio State University Sl. #1 GATEWAY Six Sigma Revolution Deming’s teaching about quality Quality initiatives: SPC, Just-in-time, TQM Motorola in 1980’s GE and AlliedSignal in 1990’s Radical Changes in products and services Companies: TI, ABB, DuPont, Ford, Dow Chemical, Johnson Controls, BASF, American Express, Nokia, Toshiba, Department of Mechanical Engineering, The Ohio State University Sl. #2 GATEWAY What is Six Sigma? Vision Philosophy Company Strategy Method Culture Tool Department of Mechanical Engineering, The Ohio State University Sl. #3 GATEWAY The Cost of Poor Quality (COPQ) Inspection Scrap Warranty Rejects Tangible Quality Costs Rework Lost sales Lost Opportunities Late delivery More Setups Hidden Factory Expediting costs Engineering change orders Lost Customer Loyalty Long cycle times Excess inventory Department of Mechanical Engineering, The Ohio State University Sl. #4 GATEWAY The Nature of the Process Off-Target xx xx x x xx On-target, less variation Variation x xx x x xxx x x x x x x x x x Six Sigma goal identifies and controls process variations and targets. Six Sigma methodology identifies processes that are off-target, Department of Mechanical Engineering, The Ohio State University Sl. #5 GATEWAY What is Six Sigma? Integrates Customer focus Breakthrough improvement Continuous improvement People Involvement Defines goals and performance metrics that yield clear and measurable business results. Applies statistical tools to achieve breakthrough financial gains Department of Mechanical Engineering, The Ohio State University Sl. #6 GATEWAY Six Sigma Focus Meeting customer needs Rapid breakthrough improvement Process capability and improvement Positive and deep culture change Real financial results that impact the bottom line Department of Mechanical Engineering, The Ohio State University Sl. #7 GATEWAY Structure / Roles Executive Management Champion Master Black Belt Black Belt Black Belt Green Belt Green Belt Green Belt Department of Mechanical Engineering, The Ohio State University Sl. #8 GATEWAY Building the 6 Team Executive Management: Set meaningful goals and propel implementation of six sigma in the organization Champion: Create general scope and set strategic direction of the projects and teams Drive project success by removing obstacles and allocating sufficient resources Master Black Belt Consults, trains and mentors the local organization on Six Sigma Black Belt: Delivers successful projects (high corporate gains) using the Breakthrough Strategy Green Belt: Delivers local projects (lower monetary gains) using the Breakthrough Strategy Other key members: Process Owner: maintains system improvements at project completion Process Sponsor: provides resources, time, money and direction of your project Financial Analyst: verifies the financial gains of the project Team members: implement the steps for six sigma success Department of Mechanical Engineering, The Ohio State University Sl. #9 GATEWAY What is Sigma? (sigma) - A Greek letter In statistics - the “standard” deviation from the average/mean Assumption of Gaussian/Normal distribution Six Sigma Methodology uses to define the capability of a process As the standard deviation of your process decreases, the “sigma level” of your process increases. Department of Mechanical Engineering, The Ohio State University Sl. #10 GATEWAY Normal/Gaussian Distribution 34.13% 34.13% 13.06% 0.13% 13.06% 2.14% -3 2.14% 2 1 m 1 2 3 68.26% 95.46% 99.73% 68.26% of the population is within +/-??1of the ? Department of Mechanical Engineering, The Ohio State University Sl. #11 0.13% GATEWAY Process Capability 6 process is to get acceptable results through: » Identification of variations » Quantification of variations » Elimination/control of variations USL LSL Defects Defects Acceptable Department of Mechanical Engineering, The Ohio State University Sl. #12 GATEWAY Six Sigma - Goal 1 2 3 4 5 6 Defects per Million Opp. 691,462 308,537 66,807 6,210 233 3.4 Department of Mechanical Engineering, The Ohio State University Sl. #13 GATEWAY Six Sigma -- Practical Meaning 99% Good (3.8 Sigma) 99.99966% Good (6 Sigma) 16,000 lost articles of mail per hour 5.4 articles lost per hour 22,000 checks deducted from the wrong bank account each hour 7.5 checks deducted from the wrong bank account each hour 500 incorrect surgical operations per week 1.7 incorrect operations per week 2 unsafe plane landings per day at O’Hare International Airport in Chicago 1 unsafe plane landing every four years 50 newborn babies dropped at birth by doctors each day 1 newborn baby dropped at birth by doctors every 2 months Department of Mechanical Engineering, The Ohio State University Sl. #14 ** Source: Six Sigma Revolution, George Eckes GATEWAY Overall Approach Define Define Problem Measure Practical Problem Analyze Statistical Problem Improve Statistical Solution Control Practical Solution Department of Mechanical Engineering, The Ohio State University Sl. #15 GATEWAY The Strategy USL LSL • Characterize • Optimize • Breakthrough T USL LSL T USL LSL T LSL’ USL’ Department of Mechanical Engineering, The Ohio State University Sl. #16 GATEWAY The 6 Sigma Breakthrough Method D Characterization M A I Define Measure Analyze Improve 1 Define project and scope 2 Establish process 3 Identify key input/outputs variables 4 Identify process capability/ measurement system 5 Establish Product Capability 6 Identify Variation Sources 7 Screen Potential Causes 8 Verify Variable Relationships 9 Validate Measurement System Optimization C Control 10 Implement Process Controls Department of Mechanical Engineering, The Ohio State University Sl. #17 GATEWAY Defining the Process Team members who understand the process Put together a flow of the process An common foundation for team activity Identification of outputs for measurement and capability studies Estimates of sigma levels at each step Department of Mechanical Engineering, The Ohio State University Sl. #18 GATEWAY Project Scope Problem statement Goals/objectives for the team Measurable gains (monetary terms) Milestone Customer needs and requirements Department of Mechanical Engineering, The Ohio State University Sl. #19 GATEWAY Process Mapping What is process mapping? Graphical depiction of the ACTUAL process What will the tool identify? All value added and non-value added process steps Process inputs (X’s) Process or product outputs (Y’s) Data collection points Department of Mechanical Engineering, The Ohio State University Sl. #20 GATEWAY Basic Flowchart Symbols Activity Start / Stop Flow Line Decision Point A Connector A Department of Mechanical Engineering, The Ohio State University Sl. #21 GATEWAY Basic Structure No Start Rework Yes • • • • A What are the steps to capture? What are the operational steps? What are the decision points? Where are the problem area? Good A Finished goods Bad Scrap Department of Mechanical Engineering, The Ohio State University Sl. #22 GATEWAY Versions of a Process What You Think It Is... What It Actually Is... What You Would Like It To Be... Start Start No Yes Start Department of Mechanical Engineering, The Ohio State University Sl. #23 GATEWAY Preparing the Process Flowchart Team Effort Engineers Line Operators Line Supervisors Maintenance Technicians Inputs to Flowcharts Brainstorming Operator Manuals (SOP’s, AOP’s, etc.) Engineering Specifications Operator Experience 5M’s and an E (Fishbone) » Machine (Equipment), Method (Procedures), Measurement, Materials, Manpower (People), Environment Department of Mechanical Engineering, The Ohio State University Sl. #24 GATEWAY Measurement Phase The input/output variables The capability of the process The defects in the process Sigma level Department of Mechanical Engineering, The Ohio State University Sl. #25 GATEWAY Purpose of Measurement Phase Identify and define defects Identify key input variables (X’s) and key output variables (Y’s) Document the existing process Establish a data collection system for your X’s and Y’s if one does not exist Evaluate measurement system for each key output variable using C&E, FMEA, etc. Department of Mechanical Engineering, The Ohio State University Sl. #26 GATEWAY The Importance of Defects • Since Six-Sigma focuses on reducing defects, it is necessary that each project definition clearly specifies the defect(s) that will be reduced • Count the number of times the letter f appears in the following statement: The final information are the results of years of scientific studies and were often combined with years of experience. We must often configure the files for the final report during the conference. Department of Mechanical Engineering, The Ohio State University Sl. #27 Six Sigma Revolution, George Eckes, pg 2 GATEWAY A simple test What was your answer? The final information are the results of years of scientific studies and were often combined with years of experience. We must often configure the files for the final report during the conference. Department of Mechanical Engineering, The Ohio State University Sl. #28 GATEWAY What Causes Defects? Variation due to: Manufacturing processes Supplier (incoming) material variation Unreasonably tight specifications (beyond customer needs) Unstable Parts and Materials Inadequate training Inadequate Design Margin Insufficient Process Capability Department of Mechanical Engineering, The Ohio State University Sl. #29 GATEWAY How Do We Improve Capability • Understand that the Outputs (Y’s) are determined by Inputs (X’s). Y = F (x1, x2, x3,…xn) • If we know enough about our X’s we can accurately predict Y without having to measure it. • If we don’t know much about our X’s, then we have to resort to inspection and test. • If can control the X’s, then we reduce the variability in Y, which decreases defects, and possibly, eliminates/reduces inspection and test. Department of Mechanical Engineering, The Ohio State University Sl. #30 GATEWAY Data Collection Plan What to measure Type of measurement Type of Data Operational Definition Data Collection Form(s) Sampling Baseline Six Sigma Department of Mechanical Engineering, The Ohio State University Sl. #31 Six Sigma Revolution, George Eckes, pg 72 GATEWAY Data Collection Data Type of Data Discrete Continuous Sampling Y-Axis Representative Random Sampling X-Axis Department of Mechanical Engineering, The Ohio State University Sl. #32 GATEWAY Metrics Metrics: What to measure? Defects per million opportunities (DPMO) drives plant-wide improvement Sigma level allows for benchmarking within and across companies Department of Mechanical Engineering, The Ohio State University Sl. #33 GATEWAY Calculating Sigma-Level • Sigma level • units: item produced or being serviced • defect: event that does not meet the customer’s requirement • opportunity: chance for a defect to occur • Calculate Defects per Million Opportunities (DPMO): DPMO = Total # defects x 1,000,000 (# of Opportunities for Error) x (# of units) • Go to a Sigma Chart and Estimate the Sigma Level Department of Mechanical Engineering, The Ohio State University Sl. #34 Six Sigma Revolution, George Eckes, pg 99 GATEWAY DPMO and Sigma Level DPMO Sigma Level DPMO Sigma Level 1000000 -3.4 158655 2.5 999997 -3.0 66807 3.0 999968 -2.5 22750 3.5 999767 -2.0 6210 4.0 998650 -1.5 1350 4.5 993790 -1.0 233 5.0 977250 -0.5 32 5.5 933193 0.0 3.40 6.0 841345 0.5 0.29 6.5 691462 1.0 0.02 7.0 500000 1.5 0.00 7.5 308538 2.0 0.00 8.0 Department of Mechanical Engineering, The Ohio State University Sl. #35 GATEWAY Tracking Trends in Metrics Our objective is to track the trends in the Metrics to establish, based on fact, our improvements. These metrics can be productivity, defects, time, yield, etc. Department of Mechanical Engineering, The Ohio State University Sl. #36 GATEWAY Purpose of the Analysis Phase Establish baseline capability for key output variables (potential and overall) Examine both the process and data for analysis Determine and validate the root causation of project problem To reduce the number of process input variables (x’s) to a manageable number To determine the presence of and potential elimination of uncontrolled variables Department of Mechanical Engineering, The Ohio State University Sl. #37 GATEWAY Three Sigma Process Centered LSL USL 1.5 Sigma Shift LSL USL Department of Mechanical Engineering, The Ohio State University Sl. #38 GATEWAY Three Sigma Process Centered LSL USL 1.5 Sigma Shift LSL USL Department of Mechanical Engineering, The Ohio State University Sl. #39 GATEWAY Six Sigma Process Centered LSL USL 1.5 Sigma Shift LSL USL Department of Mechanical Engineering, The Ohio State University Sl. #40 GATEWAY Analysis Tools Analyze Capabilities Hypothesis Testing Multi-Vari ANOVA Cause/Effect Root Cause Histogram Pareto Department of Mechanical Engineering, The Ohio State University Sl. #41 GATEWAY Purpose of the Improvement Phase Key variables are identified and validated during this process . Look to eliminate, reduce or neutralize the effects of the input or root cause. Design experiments to manipulate the key input variables (X’s) to determine their effect on the outputs (Y’s). Select the solution that impacts the root cause the most. Department of Mechanical Engineering, The Ohio State University Sl. #42 GATEWAY Design of Experiment • Full Factorials • 2K Factorials • Fractional Factorials Department of Mechanical Engineering, The Ohio State University Sl. #43 GATEWAY DOE Example Objective: To reduce consistency variation in Y Output: Variation (Lower is Better) Full Factorial Inputs: RPM Speed Time (Lo, Hi) (Lo, Hi) (Lo, Hi) Main Effects Plot 16 14 12 10 8 RPM Time Speed Department of Mechanical Engineering, The Ohio State University Sl. #44 GATEWAY Purpose of the Control Phase Develop and implement long-term control methods to sustain the gains identified Document the control plan with specific roles identified Monitor long-term delivered capability and performance Verify benefits and cost savings Department of Mechanical Engineering, The Ohio State University Sl. #45 GATEWAY Control Tools Control • Control Plan • SPC • Mistake Proofing • Automated Control Department of Mechanical Engineering, The Ohio State University Sl. #46 GATEWAY Dynamics of Execution Strategy 40 - 50 Inputs M Process Map/C&E 15 - 20 X’s A Capability/Multi-Vari 8 - 10 X’s I DOE 3-5 Critical X’s C Control Plan Department of Mechanical Engineering, The Ohio State University Sl. #47 GATEWAY Who needs Six Sigma? Service Mfg. Design 6 Method QC Sales Admin. Maint. As long as there is a process that produces an output, we can apply the Six Sigma Methodology. Every function has a customer and a deliverable. Department of Mechanical Engineering, The Ohio State University Sl. #48 GATEWAY Six Sigma Project Consideration Project is supportive of corporate objectives Project is focused on an ongoing process / recurring events that is causing defects A 70% reduction in defects results Customer (internal or external) will see or feel the result Takes 4-6 months to complete Little or no capital required Department of Mechanical Engineering, The Ohio State University Sl. #49 GATEWAY Possible Six Sigma Projects Low yield rate High operating costs High customer failure/complaints High scrap/rework High inventory/WIP High maintenance costs Supplier product quality problems Low productivity Long cycle times Low machine utilization Inaccurate information Missing information Poor process control Frequent set up requirements Long set up time Unpredictable product performance Department of Mechanical Engineering, The Ohio State University Sl. #50 GATEWAY Six Sigma Success Visible top-down leadership and commitment Education and training Recognize and focus on customer needs World-class quality Establishing meaningful, focused metrics DMAIC - Define, Measure, Analyze, Improve & Control Department of Mechanical Engineering, The Ohio State University Sl. #51 GATEWAY Credits This module is intended as a supplement to design classes in mechanical engineering. It was developed at The Ohio State University under the NSF sponsored Gateway Coalition (grant EEC-9109794). Contributing members include: Gary Kinzel…………………………………. Project supervisors Phuong Pham.……………. ………………... Primary authors L. Pham ………………………………….….. Audio voice Reference: Six Sigma Revolution, George Eckes, John Wiley & Sons, Inc., New York, 2001. Department of Mechanical Engineering, The Ohio State University Sl. #52 GATEWAY Disclaimer This information is provided “as is” for general educational purposes; it can change over time and should be interpreted with regards to this particular circumstance. While much effort is made to provide complete information, Ohio State University and Gateway do not guarantee the accuracy and reliability of any information contained or displayed in the presentation. We disclaim any warranty, expressed or implied, including the warranties of fitness for a particular purpose. We do not assume any legal liability or responsibility for the accuracy, completeness, reliability, timeliness or usefulness of any information, or processes disclosed. Nor will Ohio State University or Gateway be held liable for any improper or incorrect use of the information described and/or contain herein and assumes no responsibility for anyone’s use of the information. Reference to any specific commercial product, process, or service by trade name, trademark, manufacture, or otherwise does not necessarily constitute or imply its endorsement. Department of Mechanical Engineering, The Ohio State University Sl. #53