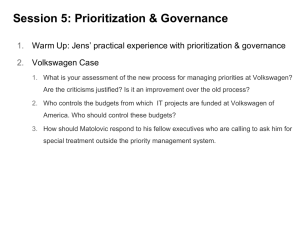

Cost Management: BMW vs. Volkswagen - Module Assignment

advertisement