IB Design Technology Core Coursebook

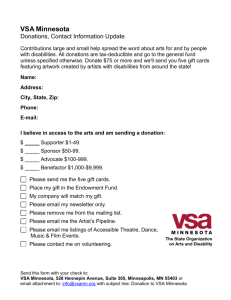

advertisement