Project Brief for Industrial Consultant

advertisement

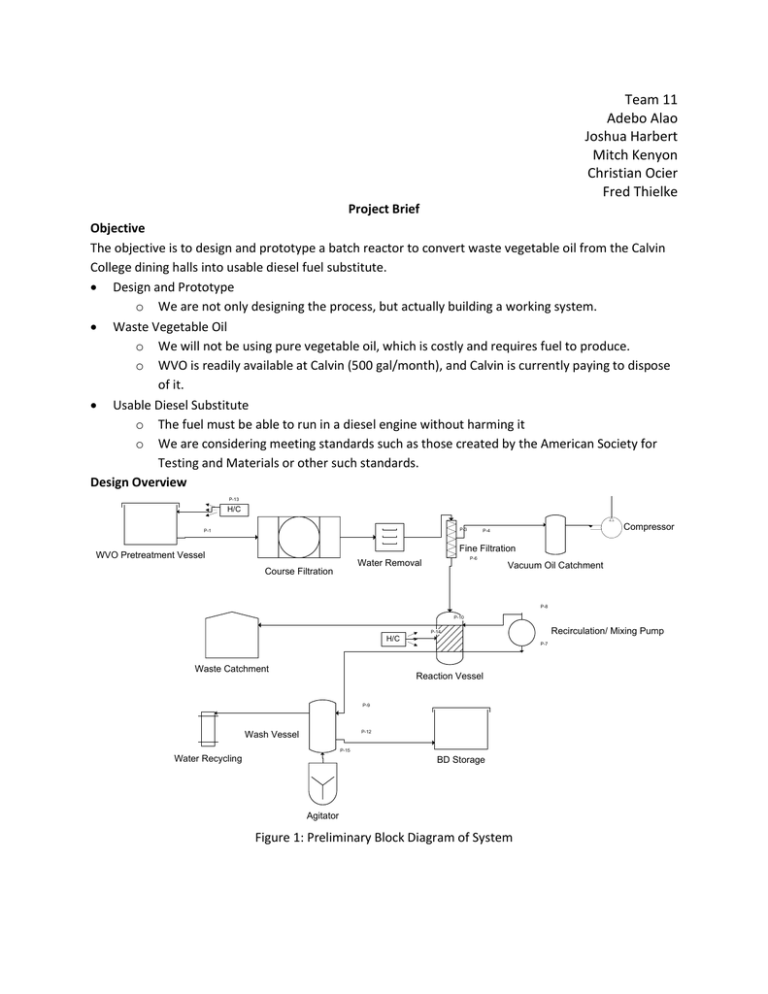

Team 11 Adebo Alao Joshua Harbert Mitch Kenyon Christian Ocier Fred Thielke Project Brief Objective The objective is to design and prototype a batch reactor to convert waste vegetable oil from the Calvin College dining halls into usable diesel fuel substitute. Design and Prototype o We are not only designing the process, but actually building a working system. Waste Vegetable Oil o We will not be using pure vegetable oil, which is costly and requires fuel to produce. o WVO is readily available at Calvin (500 gal/month), and Calvin is currently paying to dispose of it. Usable Diesel Substitute o The fuel must be able to run in a diesel engine without harming it o We are considering meeting standards such as those created by the American Society for Testing and Materials or other such standards. Design Overview P-13 H/C P-2 P-1 P-3 Compressor P-4 Fine Filtration WVO Pretreatment Vessel P-6 Water Removal Course Filtration Vacuum Oil Catchment P-8 P-10 Recirculation/ Mixing Pump P-14 H/C Waste Catchment P-7 Reaction Vessel P-11 P-9 P-12 Wash Vessel P-15 Water Recycling BD Storage Agitator Figure 1: Preliminary Block Diagram of System Filtration System It must remove solid particles which may accumulate throughout the system, reducing performance. It must remove water which drastically reduces product and can be a safety hazard when it reacts with the acid. Reactor This is where the conversion process actually takes place. We will be using a two step process. This is the best option from our research and it removes fried food smell from bio-diesel. The first reaction will be acid catalyzed and the second reaction will be base catalyzed. Washing Process In this step the reactants are separated from the biodiesel. The biodiesel will then be tested to ensure it is of high quality. Progress Michigan Energy Grant for $6000 has been awarded to our team for the development of our system. Two step process decided on Work begun on project deliverables Detailed design of the filtration system, reactor, washing process will come out of what is learned through lab experiments. Lab Progress o Researched various methods for converting Waste Vegetable Oil (WVO) into biodiesel o Researched Procedures for treating Free Fatty Acids (FFA) in WVO o Researched base and acid catalysts o Tested Pure Vegetable oil for biodiesel conversion with NaOH Catalyst o Tested Waste Vegetable oil for biodiesel conversion with NaOH Catalyst o Researched washing methods (bubble, mist and agitated) o Researched methods of testing conversion Lab Findings o Water removal from WVO is expedited with heat and moderate vacuum o Methoxide recovery is expedited with heat and moderate vacuum o Filtering the WVO feedstock for small particulates works well with filter paper and if heated along with a combination of gravity and vacuum filtration o Glycerin is very viscose, therefore the reactor that is to be built should have a conical bottom. Also the ease with which it is separated depends on the angle of the conical bottom o For the procedure used in the testing sited above, the conversion was poor. It is hypothesized that the amount of methoxide catalyst is inadequate. The nest round of test will be a set of three samples of WVO under identical conditions. The control to be tested will be different amount of methoxide catalyst. Additionally, the composition of the WVO will be assumed to be approximately the same as pure vegetable oil and the catalyst amounts will be based on this composition of a mixture of mono-,di-, and tri-glycerides.