Methods of Production

advertisement

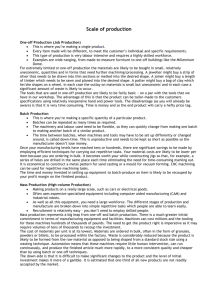

Methods of Production Intermediate II and Higher Business Management Production Methods Agriculture tends Whilst all output can be to be very land classed as production, different production intensive – methods maycould be more efficiency be appropriate for different measured in terms products or services. of output per acre/hectare Copyright: Photolibrary Group Production Methods As technology and analysis of production methodology has improved, methods have changed dramatically – what used to be labour intensive production methods are now capital intensive Copyright: iStock.com Production Methods The choice of production method and the factor inputs depends on such things as: • the nature of the product • factor costs • the scale of production California Oil is Source of Wealth and Fear Copyright: iStock.com Bottle production line Copyright: Photolibrary Group Production Decisions Market size and One-Off Order? Segment Which method? Type of Product Mass Market of product? Complexity design Factor Costs – Batch? Land, Labour and Capital Methods of Production • Job Production • Batch Production • Flow Production MASS PRODUCTION IN LARGE FACTORY Production Methods • Job Production – One-off production each item might have particular specifications • Flow Production – suitable for mass market products that are identical • Batch Production – each stage of the production process has an operation completed on it before moving on to the next stage – allows modifications to be made to products that otherwise are the same Job Production • A house built to your own design • A custom-built boat • A piece of artwork • A hand-turned wooden bowl Job Production • Advantages:- – Customers demands can be exactly met. – A high price may be charged. – Specifications can be changed even if production has started. – Workers motivated as variety of skills required. • Disadvantages:- – Expensive due to skills required. – High R&D, transport and admin costs. – Variety of equipment and tools required. – Lengthy lead times. Batch Production • A number of similar products (repeated jobs) • The same house repeated on a building site • Bakery produce - each batch may differ slightly Batch Production • Advantages – Batches can be changed to meet specific customer requirements. – Reduced need for highly skilled staff. – Machinery can be relatively standardised. • Disadvantages – Machines/workers may sit idle between stages. – Expensive machinery may be required due to less skilled staff. – Stock levels may be high. – Staff may be less motivated due to repeating the same task in batches. – If batches are small, costs will be high. Flow Production • Mass production of almost identical products • Cars • Washing machines Flow Production • Advantages – Costs spread over a large number of goods. – Bulk discounts – Huge quantities can be produced. – Automation often used which reduces chance of human error. – Machinery can work 24/7 • Disadvantages – Huge set up costs. – Individual customer requirements cannot be met. – Equipment may be inflexible. – Worker motivation can be low because of the repetitive nature of the job. – Breakdowns can be very costly.