sterile enviroment

advertisement

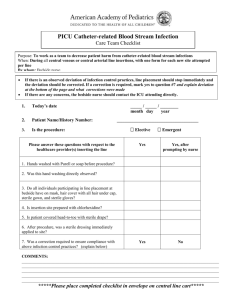

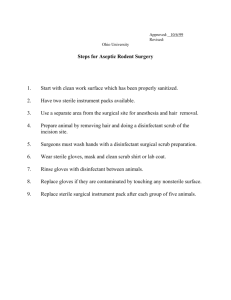

sterile environment institutional pharmacy--- 18% of CPhT workers. works with nursing home, hospital, long term care, hospice patient. they do sterile and nonsterile compounding. oral meds are given unit dose(individual package by factory or pharmacy). No fake nails allowed. •parenteral---(not rectal or in mouth)body cannot get the chance to ‘evaluate’ the drug and screen out contaminates. •aseptic technique ---keeping sterility to protect drug from contamination •greatest source of contamination is….you! person working on the product. •syringe---length, inches of needle. •gauge----bigger number=smaller needle •Extemporaneous=nonsterile •Viscosity=thickness/flowing of a liquid •Analytical balance=digital readout balance IV push--syringe into vein NPO---pt gets nothing by mouth CSP---compounded sterile preparations LR---lactated Ringer’s solution Bolus=amount of drug in ‘one shot’ You can have about 10% error---(Amt of error/needed amount)X100=% error Need 50g but got 50.74g .74g/50gx100=1.48% off request unit dose Precipitation=solid particles appear In a clear solution Aseptic tech certification—written test and Media-fill test(bacteria test) must have name, dose, lot number, expiration, NDC number Most common solvents for IV rx NS= normal saline=.9%nacl ½ ns=.45% nacl D5W=dextrose in 5% water LR=lacrated Ringers solution SWFI=sterile water PCA=pt controlled analgesia Multidose vials(MDV) will have preservatives. Good for 28 days. Single dose vials(SDV) have no preservatives. Use immediately! Nonsterile compounding for emergency=use immediately Low risk contaminants---48 hr room temp 14day=refrig Med risk=room temp=30hrs refrig=7 days High risk—room temp=24hr refrig=3days Chemotherapy technique use vertical flowhood. TPN has 1—amino acids 2---lipdis 3—dextrose 4—sterile water Plus maybe electrolytes, elements, minerals, drugs Hyperameliation=TPN sterile environment big needle has small gauge luerlok--screw on needle sterile environment • rubber stopper on bottle---insert need 45deg to avoid coring. • laminar flow hood---blows filtered air across work area. • HEPA filter---High Effiency Particulate Air filter.catches particles and organisms to .3 microns. removes 99.997% of contaminants. • old flow hoods were horizontal, wind blows at operator. vertical flow blows air downward. sterile environment • In 2012---200 pt get fungal meningitis from poor practices • USP sets standards for production of medications • USP 797----chapter 797 covers equipment, technique, and quality control for sterile products. • USP 795--chapter 795 covers nonsterile compounder responsibility=‘pills,powder’ • sterile=parenteral=USP797 sterile environment-USP ch 795 USP <795> outlines the responsibilities of the compounder, which can be summarized as being responsible for compounding preparations of acceptable strength, quality, and purity with appropriate packaging and labeling in compliance with requirements established by applicable laws and agencies (eg, state boards of pharmacy). Specifically, the responsibilities of the compounder include the following general principles: Personnel are capable and qualified to perform their assigned duties. Compounding ingredients of the appropriate identity, quality, and purity are purchased from reliable sources. All equipment used in compounding is clean, properly maintained, an used appropriately. Only authorized personnel are allowed in the immediate vicinity of the drug compounding operations. There is assurance that processes are always carried out as intended or specified and are reproducible. The compounding environment is suitable for its intended purpose and to prevent errors. Adequate procedures and records exist for investigating and correcting failures or problems in compounding, in testing, or in the preparation itself. sterile environment-usp 797 “THE INTENT OF <797> IS TO PREVENT HARM AND FATALITY TO PATIENTS THAT COULD RESULT FROM MICROBIAL CONTAMINATION (NONSTERILITY), EXCESSIVE BACTERIAL ENDOTOXINS, LARGE CONTENT ERRORS IN THE STRENGTH OF CORRECT INGREDIENTS, AND INCORRECT INGREDIENTS IN COMPOUNDED STERILE PRODUCTS (CSPs).” or..is your workplace clean enough? furniture, ceiling,shoe covers gowns, washing, gloves, hair cover..PPE 1---responsibilities 2—verify accuracy 3---training sterile environment • CSP---compounded sterile products • Clean room—has flow hood, HEPA, approved personnel only. Positive pressure room • Anteroom---has supplies, sink ISO standards-----International Organization for Standards • ISO number is particles in cubic meter of air. • USP 797 wants ISO class 5 in the laminar hood • class 7 in clean room • class 8 in anteroom ISO chart outside air has about 35million particles/ccm that are bigger than .5micron single dose vial----one time use for compounding multi dose vial---several uses ampule---single use medication in glass vial, break glass, use filter needle IV push---IV meds delivered at one time by needle continuous infusion----several hours delivery IV piggyback---additional med that hooks into main bag TPN--total parenteral nutrition into subclavian protein, carbs, fats, electrolytes by IV PPN-peripheral parenteral nutrition by arm/legs NS--normal saline--.9%NaCl 1/2NS--.45%NaCl D5W---5% dextrose in water biohazard container-- anything that touches chemo meds or IV antibiotics sharps container--for glass and needles media fill test---use broth instead of drug to discover any bacterial growth. 35c for 14 days. clean room video--https://www.youtube.com/watch?v=x440QBi_xfQ clean the BSC--https://www.youtube.com/watch?v=dcGjVs5jLvA airflow in hood---https://www.youtube.com/watch?v=Wg61LdngWlQ clean laminar flow hood-https://www.youtube.com/watch?v=rvz_MRM2ZvI aseptic handling-https://www.youtube.com/watch?v=VSSXGD79T8U Antineoplastic technique https://youtu.be/px1hzFO5kcM