WOW Project Review

advertisement

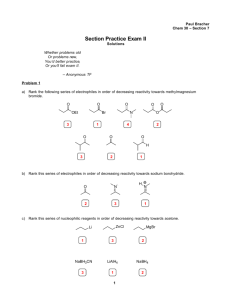

WOW Project Review Friday 2nd October 2009 Chemistry Introduction • Degradation – Bacterial degradation of lignin. Assay and bio-prospecting • Extractions – Improvements and alternative methods • Analysis – Identification of compounds • Materials – Uses and potential markets of breakdown products • Other – Links to electrospinning, biocomposites 2 Summary-last review 1. Determine suitable methods for extraction of degrading straw, using both aqueous and organic solvents. 2. Identify (from literature search) and subsequent training / obtaining of suitable equipment for analysis of extracts. 3. Develop characterisation methods for extracts based on literature protocols, in particular, looking at MALDI, GC-MS & LC-MS. 4. Develop synthetic methods for materials from potential / model breakdown products. 5. Use crude breakdown mixture to produce material based on 4. 6. Set up large scale (20 L) reactor 3 Degradation Lignin is a major component of plant cell walls OMe OMe OH HO O MeO RO OH OH OH OMe O O peroxidases laccases O OMe OH OMe OMe phenylcoumarane diarylpropane biphenyl R OH OH OH CO2H MeO R O HO OMe pinoresinol OMe OH OMe HO -aryl ether OH O HO O OMe O HO OH HO OMe OMe MeO OH O OMe OMe OMe OMe OH OH peroxidase lyase lignostilbene dioxygenase CHO 1) demethylase 2) extradiol dioxygenase HCHO OH HO MeO OMe OH C-C hydrolase HO2C MeO decarboxylase OMe CO2H HO CO2H CO2H OH CO2H decarboxylase OH extradiol dioxygenase Bacterial aromatic degraders CO2H HO demethylase OH O CO2H OH CO2H CO2H MeO HO OMe aldehyde dehydrogenase OMe HO2C OH OH Lignin-degrading microbes HO O CO2H OHC HO2C CO2H aldehyde dehydrogenase CO2H O hydratase HO CO2H aldolase CO2H CO2 O OH HO O CO2H O O CO2H 2x CO2H Fluorescent Assay for Lignin Degradation LIGNIN LIGNIN HO HO lignin degrader attach fluorophore Fluorescence change OMe OMe OH O Could be performed in 96-well microtitre plate reader O Fl Assay can distinguish degraders from non-degraders: Time dependence (0-2 hr) Change in fluore se ce nce in the firs t 10 m in 1000 Fluore s e nce Vs Tim e For P. Putida Supe rnatant 18500 500 0 17500 30 ul 17000 Fluorescence Fluorsence 18000 B. Subtillis P.Putida -500 Rhodococcus RHA1 Rhodococcus sp Nocardia autotrophica -1000 16500 Streptomyces Viridosporus Leuconostoc Mesentoides -1500 16000 0 20 40 60 80 100 120 -2000 Tim e (m in) Paper Submitted to Molecular Biosystems Non-degraders Continuous UV-VIS Assay using Nitrated Lignin LIGNIN LIGNIN O O O HO tetranitromethane OMe O HO OMe O2N OH lignin breakdown O increase in A400 OMe O2N OH can be performed in microtitre plate format OH Time dependence (0-20 min) Specificity of bacterial lignin degraders towards MWL from pine, wheat straw & miscanthus: Tim e de pendance 0.0576 0.0574 0.0572 Absorbance 0.057 0.0568 0.0566 0.0564 RHA1 0.0562 0.004 0.056 0.0558 0 5 10 15 20 25 0.003 Time (min) No lignin Wheat Myscantus Pine Absorbance 0.002 Distinguishes lignin degraders from non-degraders 0.001 0 Rhodococcus RHA1 not selective -0.001 -0.002 Bacterial degraders 0.0035 N. Autotrophica 0.003 0.0025 0.0025 0.001 0.0005 0 -0.0005 0.002 P.Put ida R. RHA1 0.0015 R. Sp. S. Viridosporus N. aut ot rophica L.mesent eroides B. Subt illis Absorbance Absorbance 0.002 0.0015 0.001 0.0005 0 No lignin Wheat Myscanthus Pine Nocardia autotrophica shows selectivity for pine lignin -0.0005 -0.001 -0.001 -0.0015 Paper Submitted to Molecular Biosystems Extractions Large Scale Extraction • 1.5 kg (wet) of P.chrysosporium-degraded straw was extracted using 20 L reactor • 12 L of water and 8 L of THF used to extract straw • THF was used due to combination of interesting peaks from LTQ analysis and mass recovered in previous trials Extract Mass (g) Percentage of total Percentage of total (wet) (dry) Aqueous 156.88 10.6% 38.6% Organic 14.5 0.98% 3.57% Dry Straw 235.3 15.9% 57.9% Water content - 72.7% - 9 Hexane Extraction • Recent research suggests that hexane can be used to extract triglycerides and fatty acids from straw.1 • Straw placed in soxhlet and extracted with hexane (200 mL) for 24 h. • Fatty acid and triglyceride mixture is collected in the distillation flask away from the straw 1 I. M. G. Lopes, M. G. Bernado-Gil, Eur. J. Lipid. Sci. Technol., 2005, 107, 12-19 10 Hexane Extraction - Results Straw Type Processing Extracted mass / mg % dry mass extracted Untreated None 80 1.84 Untreated Water 24 0.55 Untreated Chopped 100 1.77 P. Chrysosporium None 310 7.40 P. Chrysosporium Water 40 0.96 P. Chrysosporium Chopped 230 5.35 It would appear that a higher content is made available by degradation, but it is unknown to the origin of the material. 11 Analysis HPLC traces with time Non-degrader Bacillus subtilis shows no change Degrader Pseudomonas putida GC-MS data for small scale lignocellulose degradation trials GC-MS total ion chromatogram with EI ionisation for Rhodococcus RHA1 incubated with wheat straw lignocellulose for 7 days at 30 oC. O OH O OH 1 Mass spectrum of peak at RT 7.02 min, assigned to monosilylated derivative of ketone (1), m/z 268 (MSiMe3)+, 253 (M-SiMe3CH3)+. Analysis • Extracts have been analysed using LTQ-MS at HRI – Separates and detects using UV and MS 15 Comparison of LTQ data - standards Vanillic Acid 16 Aromatic metabolites identified (so far) Compound 1 O OH LC-MS Retention time (min) LC-MS m/z GC-MS Retention time (min) GC-MS m/z (silylated) Observed with.. 4.29 235 MK+ 7.02 268 M+ 253 -CH3 P. Putida 6hr, 1d, 3d Rhodococcus RHA1 2hr, 4hr Miscanthus & wheat straw 4.56 209 MNa+ 225 MK+ 7.71 243 M+ 228 -CH3 P. Putida (straw) 7d Rhodococcus RHA1 Miscanthus 1d, straw 2d 5.25 195 MH+ 5.27 251 M-CH3 P. Putida 6hr Rhodococcus RHA1 2hr, 6hr Miscanthus only 5.76 251 MK+ 6.03 341 M-CH3 P. Putida 6hr Rhodococcus RHA1 4hr, 6hr Miscanthus only 9.09 169 MH+ OCH3 OH 2 COOH HO 3 O COOH CO2H OCH3 OH COOH 4 H3CO 5 COOH OH COOH OCH3 OH Rhodococcus RHA1 6hr Miscanthus only Ferulic acid. 379 papers in 2008-9 on biological activity alone £1 per 1g Anti-oxidant Active breast cancer, liver cancer Active ingredient in anti-ageing creams / plumping creams Carboxy vanillic acid. 0 papers in 2008-9 Potential use as fine chemical building block. Vanillic acid precursor. Diacid for use in polyesters and polyamides Other potential major degradation productsyet to be fully identified from wheat straw Derivative of Gallic acid. Anti-fungal, anti-viral, anti-oxidant. Gallic acid is used in dyes and inks. No current market. Potential in poly-ethers, -ester or -urethanes Vanillic acid precursor? Diacid for use in polyesters and polyamides Hexane Extraction - Analysis Process Degraded, Water Degraded Untreated, Chopped Untreated Degraded, Chopped FA 2a 2b 3a 3b 5a 5b 6a 6b 7a 7b 14:0 2.19 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 16:0 20.49 24.70 12.52 100.00 42.88 33.98 16.09 46.10 38.19 27.85 18:0 3.46 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 18:1 10.98 14.99 0.00 0.00 0.00 0.00 0.00 11.68 0.00 0.00 18:2 5.33 7.51 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 20:3 8.17 10.05 0.00 0.00 24.29 46.10 13.87 27.38 61.81 46.72 20:4 0.00 0.00 0.00 0.00 0.00 19.91 0.00 14.84 0.00 16.20 22:0 6.42 8.89 0.00 0.00 16.70 0.00 0.00 0.00 0.00 0.00 23:0/22:2 0.00 0.00 0.00 0.00 0.00 0.00 18.87 0.00 0.00 0.00 24:0 5.12 6.79 0.00 0.00 16.12 0.00 0.00 0.00 0.00 0.00 22:6 37.84 27.07 87.48 0.00 0.00 0.00 0.00 0.00 0.00 20 0.00 Materials Hexane Extraction - Potential • Must be carried out before the water extraction • Fatty acids have potential applications in: – Soaps, personal care, perfumes – Polymeric species (e.g. plastics, rubber) – Lubricants, cleaners, coatings – Fatty acid derivatives (e.g. biofuel) – Food and related supplements (e.g. bio oils) • Around 7 – 8 % by weight of the dry mass is a significant portion of material 22 n=3 n=2 n=4 n=5 Tungstan mediated fatty acid functionalisation: J. Appl. Poly. Science, In Prep Products from Extractions • Conversion of ‘model feedstocks’ into polyurethane materials • Two initial materials were identified Beneficial effects in atherosclerosis, osteoporosis, diabetes mellitus and certain cancers. Use as dietary supplements / plant extracts has been steadily increasing. Anti-oxidants. Vanillin derivative. Used in fragrances, flavouring. Annual demand for vanillin = 12,000 tons. Natural source = 1200 tons, synthesis = 10,800 tons 24 Chrysin: a naturally occurring flavone TGA Curve for Chrysin derivatives - N2 100 % Mass Change 90 80 70 60 50 25 125 225 325 Temperature / oC Polyurethanes from Flavone derivatives: J. Appl. Poly. Science, In Prep Polyurethanes from Vanillin derivatives: J. Appl. Poly. Science, In Prep Other Alternative uses of lignin • Filler in biocomposite structures – May promote resin / matrix adhesion between for natural fibres • Use in electrospun nanofibres – Solutions not ideal for electrospinning – Potential to be co-spun with other polymers (e.g. PVOH) – Degradation products may have beneficial anti-oxidant properties which can be incorporated 28 A (DoE) approach to material properties of electrospun nanofibres. SR Coles, AJ Clark, K Kirwan et al. J. Appl. Poly. Science, 2009 Accepted Future work Biodegradation Isolation and purification of degradation enzymes from bacteria. Analysis Continued identification of novel lignin degradation products. Preparation of LC-MS standards for unambiguous identification. Materials Identification of molecules for further study. Scale up of chosen molecules (synthesis) Identification of potential industrial partners (medical / cosmetic ?). Evaluation of estolides as lubricants (Fuchs). Evaluation as novel fatty amides as additives in paints (Akzo Nobel). Evaluation of vanillin and flavone polymers for anti-oxidant / UV stability. Preparation of materials from gallic acid, ferulic acid derivatives. Other Evaluation of lignin incorporation in electrospun fibres and composites.