A_5_8_Cost_Analysis_100g_appendix

advertisement

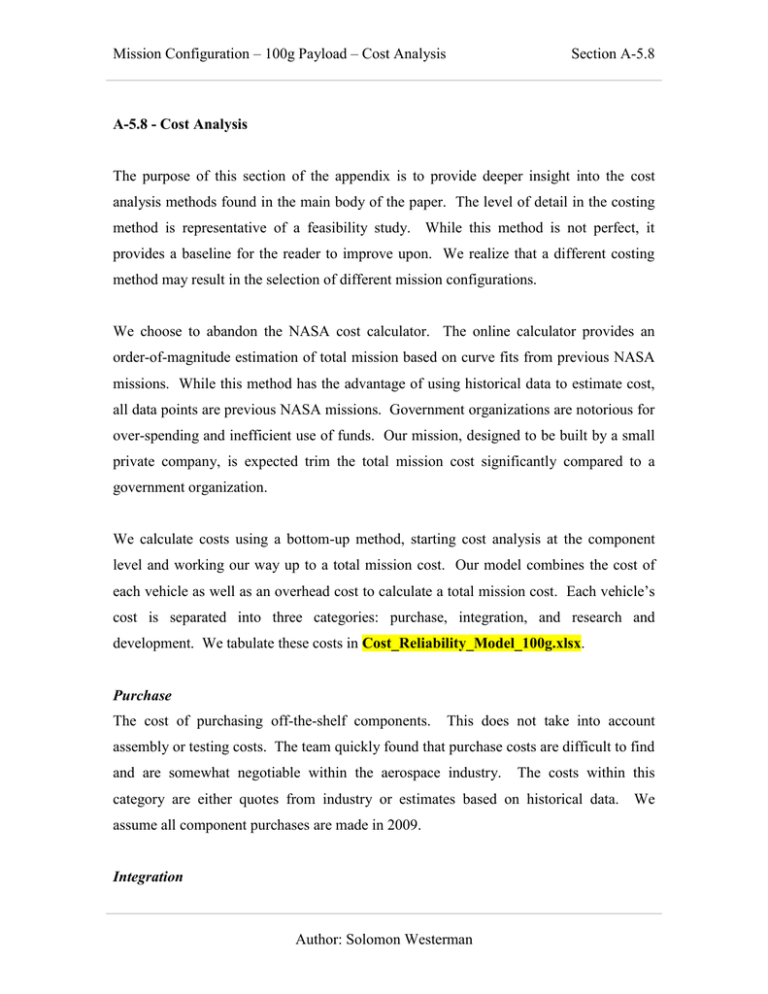

Mission Configuration – 100g Payload – Cost Analysis Section A-5.8 A-5.8 - Cost Analysis The purpose of this section of the appendix is to provide deeper insight into the cost analysis methods found in the main body of the paper. The level of detail in the costing method is representative of a feasibility study. While this method is not perfect, it provides a baseline for the reader to improve upon. We realize that a different costing method may result in the selection of different mission configurations. We choose to abandon the NASA cost calculator. The online calculator provides an order-of-magnitude estimation of total mission based on curve fits from previous NASA missions. While this method has the advantage of using historical data to estimate cost, all data points are previous NASA missions. Government organizations are notorious for over-spending and inefficient use of funds. Our mission, designed to be built by a small private company, is expected trim the total mission cost significantly compared to a government organization. We calculate costs using a bottom-up method, starting cost analysis at the component level and working our way up to a total mission cost. Our model combines the cost of each vehicle as well as an overhead cost to calculate a total mission cost. Each vehicle’s cost is separated into three categories: purchase, integration, and research and development. We tabulate these costs in Cost_Reliability_Model_100g.xlsx. Purchase The cost of purchasing off-the-shelf components. This does not take into account assembly or testing costs. The team quickly found that purchase costs are difficult to find and are somewhat negotiable within the aerospace industry. The costs within this category are either quotes from industry or estimates based on historical data. assume all component purchases are made in 2009. Integration Author: Solomon Westerman We Mission Configuration – 100g Payload – Cost Analysis The cost associated with manufacturing a vehicle. Section A-5.8 In reality, this cost would be a function many variables, including vehicle complexity and problems encountered during assembly. In this project, we make the simplifying assumption that the integration cost is only a function of the vehicle mass. We base the integration cost on a manned lunar architecture proposal by an aerospace consulting firm. (Herbert) We expect manned lunar missions to be more expensive, per kilogram, than unmanned missions. However, large manned missions have an economy of scale that may reduce the cost per kilogram relative to smaller missions. In our analysis, we assume these factors wash out and use a $10k per kilogram estimate for integration costs. We believe this is an appropriate first-order approximation to the integration costs encountered in the aerospace industry. Research and Development The cost of developing or refining a technology in-house. In many cases, off-the-shelf components matching our requirements did not exist or were too expensive to be considered. In some of these cases, we decide to design a system in-house in an attempt to reduce the overall system cost. The research and development cost is an estimation of the cost to design, build, and test a system we design in-house. This cost is a function of the success rate of the system as well as the number of engineers employed, their salaries, and testing equipment costs. We assume each month of research and development increases the success rate of the system by two percent with cap of 95%. We employ twenty engineers at a cost of $150k each per year ($12.5k per month) and add $50k of testing equipment per month. Overhead Overhead is a separate category of cost independent of vehicle. Overhead represents the recurring cost of maintaining a functioning company. This cost includes salary expense for fifteen engineers at $150k per year. We purchase three Satellite Tool Kit licenses at Author: Solomon Westerman Mission Configuration – 100g Payload – Cost Analysis Section A-5.8 $200k per year and fifteen MATLAB licenses at $15k per year. Communication rental expense for ground stations is estimated at $1M flat cost. Our analysis does not include overhead costs associated with building rental, computer hardware, or miscellaneous expenses. We expect the overhead cost to be under-estimated. A company with fifteen engineers designing components is meager. Although some engineers are “employed” through the integration cost, the total overhead cost represents a bare-bones company. We used a bare-bones approach for overhead cost in an attempt to make direct profit from the GLXP. Cash flow Our analysis incorporates inflation at a rate of 3.8%, the average inflation of the U.S. dollar in the past eight years. (Inflation Data) We assume a constant value for simplicity. We purchase the Dnepr launch vehicle in late 2011. We assume an even distribution of overhead cost over four years from 2009 until mission completion in 2012. Integration and research and development costs are evenly distributed over three years from 2009 until launch in 2011. Figure X.X.X-X depicts the cash flow for the 100g mission. This spreadsheet is available on the course website as CashFlow_100g.xlsx. Author: Solomon Westerman Mission Configuration – 100g Payload – Cost Analysis Section A-5.8 Net operating loss: $4.83M in 2009 dollars Figure X.X.X-X, Cash Flow Diagram for the 100g Mission. Overhead, purchase, integration, research and development, as well as launch costs are shown. The 100g mission’s net operating loss is $4.83M in 2009 dollars. (Solomon Westerman) Author: Solomon Westerman