Chapter_07_Lecture_08_to_11_w08_431_MRP_JIT

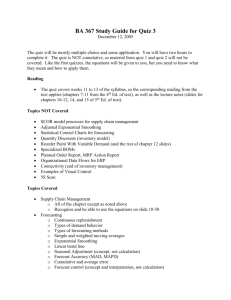

advertisement

LESSON 8: MATERIAL REQUIREMENTS PLANNING Outline • • • • • • Hierarchy of Production Decisions MRP and its importance Input and Output of an MRP system MRP Calculation Lot Sizing Lot Sizing with Capacity Constraint 1 Hierarchy of Production Decisions • The next slide presents a schematic view of the aggregate production planning function and its place in the hierarchy of the production planning decisions. • Forecasting: First, a firm must forecast demand for aggregate sales over the planning horizon. • Aggregate planning: The forecasts provide inputs for determining aggregate production and workforce levels over the planning horizon. • Master production schedule (MPS): Recall, that the aggregate production plan does not consider any “real” product but a “fictitious” aggregate product. The MPS translates the aggregate plan output in terms of specific production goals by product and time period. For example, 2 Hierarchy of Production Decisions Forecast of Demand Aggregate Planning Master Production Schedule Inventory Control Operations Scheduling Vehicle Routing 3 Hierarchy of Production Decisions suppose that a firm produces three types of chairs: ladderback chair, kitchen chair and desk chair. The aggregate production considers a fictitious aggregate unit of chair and find that the firm should produce 550 units of chairs in April. The MPS then translates this output in terms of three product types and four work-weeks in April. The MPS suggests that the firm produce 200 units of desk chairs in Week 1, 150 units of ladder-back chair in Week 2, and 200 units of kitchen chairs in Week 3. • Material Requirements Planning (MRP): A product is manufactured from some components or subassemblies. For example a chair may require two back legs, two front legs, 4 leg supports, etc. While forecasting, aggregate plan 4 Hierarchy of Production Decisions Master Production Schedule April 1 Ladder-back chair 2 3 Aggregate production plan for chair family 4 5 150 6 7 8 150 200 Kitchen chair Desk chair May 200 120 120 200 550 200 790 5 Hierarchy of Production Decisions and MPS consider the volume of finished products, MRP plans for the components, and subassemblies. A firm may obtain the components by in-house production or purchasing. MRP prepares a plan of in-house production or purchasing requirements of components and subassemblies. • Scheduling: Scheduling allocates resource over times in order to produce the products. The resources include workers, machines and tools. • Vehicle Routing: After the products are produced, the firm may deliver the products to some other manufacturers, or warehouses. The vehicle routing allocates vehicles and prepares a route for each vehicle. 6 Hierarchy of Production Decisions Materials Requirement Planning Back legs Back slats Seat cushion Leg supports Seat-frame boards Front legs 7 Material Requirements Planning • The demands for the finished goods are obtained from forecasting. These demands are called independent demand. • The demands for the components or subassemblies depend on those for the finished goods. These demands are called dependent demand. • Material Requirements Planning (MRP) is used for dependent demand and for both assembly and manufacturing • If the finished product is composed of many components, MRP can be used to optimize the inventory costs. 8 Importance of an MRP System • Next two slides explain the importance of an MRP system. The first one shows inventory levels when an MRP system is not used. The next one shows the same when an MRP system is used. • The chart at the top shows inventory levels of the finished goods and the chart on the bottom shows the same of the components. • If the production is stopped (like it is at the beginning of the chart), the finished goods inventory level decreases because of sales. However, the component inventory level remains unchanged. When the production resumes, the finished goods inventory level increases, but the component inventory level decreases. 9 Importance of an MRP System Inventory without an MRP System 10 Importance of an MRP System Inventory with an MRP System 11 Importance of an MRP System • Without an MRP system: – Component is ordered at time A, when the inventory level of the component hits reorder point, R – So, the component is received at time B. – However, the component is actually needed at time C, not B. So, the inventory holding cost incurred between time B and C is a wastage. • With an MRP system: – We shall see in this lesson that given the production schedule of the finished goods and some other information (see the next slide), it is possible to predict the exact time, C when the component will be required. Order is placed carefully so that it is received at time C. 12 MRP Input and Output • MRP Inputs: – Master Production Schedule (MPS): The MPS of the finished product provides information on the net requirement of the finished product over time. – Bill of Materials: For each component, the bill of materials provides information on the number of units required, source of the component (purchase/ manufacture), etc. There are two forms of the bill of materials: • Product Structure Tree: The finished product is shown at the top, at level 0. The components assembled to produce the finished product is shown at level 1 or below. The sub-components used to produce the components at level 1 is 13 MRP Input and Output Master Production Schedule Forecasts Bill of Materials file MRP computer program Inventory file To Production Reports Orders To Purchasing 14 MRP Input and Output shown at level 2 or below, and so on. The number in the parentheses shows the requirement of the item. For example, “G(4)” implies that 4 units of G is required to produce 1 unit of B. The levels are important. The net requirements of the components are computed from the low levels to high. First, the net requirements of the components at level 1 is computed, then level 2, and so on. 15 MRP Input and Output • Bill of Materials: For each item, the name, number, source, and lead time of every component required is shown on the bill of materials in a tabular form. – Inventory file: For each item, the number of units on hand is obtained from the inventory file. • MRP Output: – Every required item is either produced or purchased. So, the report is sent to production or purchasing. 16 Bill of Materials: Product Structure Tree Level 0 Level 1 Level 2 Level 3 17 Bill of Materials Item B C D E BILL OF MATERIALS Product Description: Ladder-back chair Item: A Component Quantity Source Required Description Ladder-back 1 Manufacturing Front legs 2 Purchase Leg supports 4 Purchase Seat 1 Manufacturing 18 Bill of Materials Item H I BILL OF MATERIALS Product Description: Seat Item: E Component Quantity Required Description Seat frame 1 Seat cushion 1 Source Manufacturing Purchase 19 On Hand Inventory and Lead time Component Units in Inventory Lead time (weeks) Seat Subassembly 25 2 Seat frame 50 3 Seat frame boards 75 1 20 MRP Calculation • Now, the MRP calculation will be demonstrated with an example. • Suppose that 150 units of ladder-back chair is required. • The previous slide shows a product structure tree with seat subassembly, seat frames, and seat frame boards. For each of the above components, the previous slide also shows the number of units on hand. • The net requirement is computed from top to bottom. Since 150 units of ladder-back chair is required, and since 1 unit of seat subassembly is required for each unit of ladder-back chair, the gross requirement of seatsubassembly is 1501 =150 units. Since there are 25 units of seat-subassembly in the inventory, the net requirement of the seat-subassembly is 150-25 = 125 21 MRP Calculation units. Since 1 unit of seat frames is required for each unit of seat subassembly, the gross requirement of the seat frames is 1251 = 125 units. (Note that although it follows from the product structure tree that 1 unit of seat frames is required for each unit of ladder-back chair, the gross requirement of seat frames is not 150 units because each of the 25 units of seat-subassembly also contains 1 unit of seat frames.) Since there are 50 units of seat frames in the inventory, the net requirement of the seat frames is 125-50 = 75 units. The detail computation is shown in the next two slides. • A similar logic is used to compute the time of order placement. 22 MRP Calculation Quantity of ladder-back chairs to be produced Gross requirement, seat subassembly Less seat subassembly in inventory Net requirement, seat subassembly Gross requirement, seat frames Less seat frames in inventory Net requirement, seat frames Gross requirement, seat frame boards Less seat frame boards in inventory Net requirement, seat frame boards Units 150 25 50 75 Assume that 150 units of ladder-back chairs are to be produced at the end of week 15 23 MRP Calculation: Time of Order Placement Week Complete order for seat subassembly Minus lead time for seat subassembly Place an order for seat subassembl y Complete order for seat frames Minus lead time for seat frames Place an order for seat frames Complete order for seat frame boards Minus lead time for seat frame boards Place an order for seat frame boards 14 2 3 1 Assume that 150 units of ladder-back chairs are to be produced at the end of week 15 and that there is a one-week lead time for ladder-back chair assembly 24 MRP Calculation: Some Definitions • Scheduled Receipts: – Items ordered prior to the current planning period and/or – Items returned from the customer • Lot-for-lot (L4L) – Order quantity equals the net requirement – Sometimes, lot-for-lot policy cannot be used. There may be restrictions on minimum order quantity or order quantity may be required to multiples of 50, 100 etc. 25 MRP Calculation Example 1: Each unit of A is composed of one unit of B, two units of C, and one unit of D. C is composed of two units of D and three units of E. Items A, C, D, and E have on-hand inventories of 20, 10, 20, and 10 units, respectively. Item B has a scheduled receipt of 10 units in period 1, and C has a scheduled receipt of 50 units in Period 1. Lot-for-lot (L4L) is used for Items A and B. Item C requires a minimum lot size of 50 units. D and E are required to be purchased in multiples of 100 and 50, respectively. Lead times are one period for Items A, B, and C, and two periods for Items D and E. The gross requirements for A are 30 in Period 2, 30 in Period 5, and 40 in Period 8. Find the planned order releases for all items. 26 MRP Calculation Level 0 Level 1 Level 2 27 MRP Calculation Period 1 Item Gross Requirements A Scheduled receipts LT= On hand from prior period Net requirements Q= Time-phased Net Requirements Planned order releases Planned order delivery 2 3 4 5 6 7 8 9 10 28 MRP Calculation Period 1 2 3 Item Gross 30 Requirements A Scheduled receipts LT= On hand from 20 prior period 1 Net WK requirements Q= Time-phased Net Requirements L4L Planned order releases Planned order delivery All the information above are given. 4 5 30 6 7 8 9 10 40 29 MRP Calculation Period 1 2 3 4 5 6 Item Gross 30 30 Requirements A Scheduled receipts LT= On hand from 20 20 prior period 1 Net WK requirements -Q= Time-phased Net Requirements L4L Planned order releases Planned order delivery 20 units are just transferred from Period 1 to 2. 7 8 9 10 40 30 MRP Calculation Period 1 2 3 4 5 6 7 8 9 10 Item Gross 30 30 40 Requirements A Scheduled receipts LT= On hand from 20 20 prior period 1 Net WK requirements -- 10 Q= Time-phased Net 10 Requirements L4L Planned order 10 releases Planned order 10 delivery 31 The net requirement of 30-20=10 units must be ordered in week 1. MRP Calculation Period 1 2 3 4 5 6 Item Gross 30 30 Requirements A Scheduled receipts LT= On hand from 20 20 0 0 0 prior period 1 Net WK requirements -- 10 Q= Time-phased Net 10 Requirements L4L Planned order 10 releases Planned order 10 delivery On hand in week 3 is (20+10)-30=0 unit. 7 8 9 10 40 32 MRP Calculation Period 1 2 3 4 5 6 7 8 9 10 Item Gross 30 30 40 Requirements A Scheduled receipts LT= On hand from 20 20 0 0 0 prior period 1 Net 30 WK requirements -- 10 Q= Time-phased Net 30 10 Requirements L4L Planned order 30 10 releases Planned order 10 30 delivery 33 The net requirement of 30-0=30 units must be ordered in week 4. MRP Calculation Period 1 2 3 4 5 6 7 8 9 10 Item Gross 30 30 40 Requirements A Scheduled receipts LT= On hand from 20 20 0 0 0 0 0 0 prior period 1 Net 30 40 WK requirements -- 10 Q= Time-phased Net 30 40 10 Requirements L4L Planned order 30 40 10 releases Planned order 10 30 40 delivery 34 The net requirement of 40-0=30 units must be ordered in week 7. MRP Calculation Period 1 2 3 4 5 6 7 8 9 10 Item Gross 30 30 40 Requirements A Scheduled receipts LT= On hand from 20 20 0 0 0 0 0 0 0 0 prior period 1 Net 30 40 WK requirements -- 10 Q= Time-phased Net 30 40 10 Requirements L4L Planned order 30 40 10 releases Planned order 10 30 40 delivery 35 The net requirement of 40-0=30 units must be ordered in week 7. MRP Calculation Period 1 Item Gross Requirements B Scheduled receipts LT= On hand from prior period Net requirements Q= Time-phased Net Requirements Planned order releases Planned order delivery 2 3 4 5 Exercise 6 7 8 9 10 36 MRP Calculation Period 1 Item Gross Requirements C Scheduled receipts LT= On hand from prior period Net requirements Q= Time-phased Net Requirements Planned order releases Planned order delivery 2 3 4 5 Exercise 6 7 8 9 10 37 MRP Calculation Period 1 Item Gross Requirements D Scheduled receipts LT= On hand from prior period Net requirements Q= Time-phased Net Requirements Planned order releases Planned order delivery 2 3 4 5 Exercise 6 7 8 9 10 38 MRP Calculation Period 1 Item Gross Requirements E Scheduled receipts LT= On hand from prior period Net requirements Q= Time-phased Net Requirements Planned order releases Planned order delivery 2 3 4 5 Exercise 6 7 8 9 10 39 READING AND EXERCISES Lesson 8 Reading: Section 7.1 pp. 355-364 (4th Ed.), pp. 346-358 (5th Ed.) Exercise: 4 and 9 pp. 364-366 (4th Ed.), pp. 356-358 (5th Ed.) 40 LESSON 9: MATERIAL REQUIREMENTS PLANNING: LOT SIZING Outline • Lot Sizing • Lot Sizing Methods – Lot-for-Lot (L4L) – EOQ – Silver-Meal Heuristic – Least Unit Cost (LUC) – Part Period Balancing 41 Lot-Sizing • In Lesson 21 – We employ lot for lot ordering policy and order production as much as it is needed. – Exception are only the cases in which there are constraints on the order quantity. – For example, in one case we assume that at least 50 units must be ordered. In another case we assume that the order quantity must be a multiple of 50. • The motivation behind using lot for lot policy is minimizing inventory. If we order as much as it is needed, there will be no ending inventory at all! 42 Lot-Sizing • However, lot for lot policy requires that an order be placed each period. So, the number of orders and ordering cost are maximum. • So, if the ordering cost is significant, one may naturally try to combine some lots into one in order to reduce the ordering cost. But then, inventory holding cost increases. • Therefore, a question is what is the optimal size of the lot? How many periods will be covered by the first order, the second order, and so on until all the periods in the planning horizon are covered. This is the question of lot sizing. The next slide contains the statement of the lot sizing problem. 43 Lot-Sizing • The lot sizing problem is as follows: Given net requirements of an item over the next T periods, T >0, find order quantities that minimize the total holding and ordering costs over T periods. • Note that this is a case of deterministic demand. However, the methods learnt in Lessons 11-15 are not appropriate because – the demand is not necessarily the same over all periods and – the inventory holding cost is only charged on ending inventory of each period 44 Lot-Sizing • Although we consider a deterministic model, keep in mind that in reality the demand is uncertain and subject to change. • It has been observed that an optimal solution to the deterministic model may actually yield higher cost because of the changes in the demand. Some heuristic methods give lower cost in the long run. • If the demand and/or costs change, the optimal solution may change significantly causing some managerial problems. The heuristic methods may not require such changes in the production plan. • The heuristic methods require fewer computation steps and are easier to understand. • In this lesson we shall discuss some heuristic methods. The optimization method is discussed in the text, Appendix 7-A, pp 406-410 (not included in the course).45 Lot-Sizing • Some heuristic methods: – Lot-for-Lot (L4L): • Order as much as it is needed. • L4Lminimizes inventory holding cost, but maximizes ordering cost. – EOQ: • Every time it is required to place an order, lot size equals EOQ. • EOQ method may choose an order size that covers partial demand of a period. For example, suppose that EOQ is 15 units. If the demand is 12 units in period 1 and 10 units in period 2, then a lot size of 15 units covers all of period 1 and only (15-12)=3 units of period 2. So, one does not save the ordering cost of period 2, but carries some 3 units in 46 Lot-Sizing • Some heuristic methods: the inventory when that 3 units are required in period 2. This is not a good idea because if an order size of 12 units is chosen, one saves on the holding cost without increasing the ordering cost! • So, what’s the mistake? Generally, if the order quantity covers a period partially, one can save on the holding cost without increasing the ordering cost. The next three methods, SilverMeal heuristic, least unit cost and part period balancing avoid order quantities that cover a period partially. These methods always choose an order quantity that covers some K periods, K >0. • Be careful when you compute EOQ. Express both holding cost and demand over the same period. If the holding cost is annual, use annual demand. If the holding cost is weekly, use weekly demand. 47 Lot-Sizing • Some heuristic methods: – Silver-Meal Heuristic • As it is discussed in the previous slide, Silver-Meal heuristic chooses a lot size that equals the demand of some K periods in future, where K>0. • If K =1, the lot size equals the demand of the next period. • If K =2, the lot size equals the demand of the next 2 periods. • If K =3, the lot size equals the demand of the next 3 periods, and so on. • The average holding and ordering cost per period is computed for each K=1, 2, 3, etc. starting from K=1 and increasing K by 1 until the average cost per period starts increasing. The best K is the last one up to which the average cost per period decreases. 48 Lot-Sizing • Some heuristic methods: – Least Unit Cost (LUC) • As it is discussed before, least unit cost heuristic chooses a lot size that equals the demand of some K periods in future, where K>0. • The average holding and ordering cost per unit is computed for each K=1, 2, 3, etc. starting from K=1 and increasing K by 1 until the average cost per unit starts increasing. The best K is the last one up to which the average cost per unit decreases. • Observe how similar is Silver-Meal heuristic and least unit cost heuristic. The only difference is that Silver-Meal heuristic chooses K on the basis of average cost per period and least unit cost on average cost per unit. 49 Lot-Sizing • Some heuristic methods: – Part Period Balancing • As it is discussed before, part period balancing heuristic chooses a lot size that equals the demand of some K periods in future, where K>0. • Holding and ordering costs are computed for each K=1, 2, 3, etc. starting from K=1 and increasing K by 1 until the holding cost exceeds the ordering cost. The best K is the one that minimizes the (absolute) difference between the holding and ordering costs. • Note the similarity of this method with the SilverMeal heuristic and least unit cost heuristic. Part period balancing heuristic chooses K on the basis of the (absolute) difference between the holding and ordering costs. 50 Lot-Sizing • Some important notes – Inventory costs are computed on the ending inventory. – L4L minimizes carrying cost – Silver-Meal Heuristic, LUC and Part Period Balancing are similar – Silver-Meal Heuristic and LUC perform best if the costs change over time – Part Period Balancing perform best if the costs do not change over time – The problem extended to all items is difficult to solve 51 Lot-Sizing Example 2: The MRP gross requirements for Item A are shown here for the next 10 weeks. Lead time for A is three weeks and setup cost is $10. There is a carrying cost of $0.01 per unit per week. Beginning inventory is 90 units. Week 1 2 3 4 5 Gross requirements Week 30 6 50 7 10 8 20 9 70 10 Determine the lot sizes. Gross requirements 80 20 60 200 50 52 Lot-Sizing: Lot-for-Lot Period 1 2 3 4 5 6 7 8 9 10 Gross 30 50 10 20 70 80 20 60 200 50 Requirements Beginning 90 60 10 0 Inventory Net 0 0 0 20 Requirements Time-phased Net Requirements Planned order Release Planned Deliveries Ending 60 10 0 Inventory 53 Use the above table to compute ending inventory of various periods. Lot-Sizing: Lot-for-Lot Period 1 2 3 4 5 6 7 8 9 10 Gross 30 50 10 20 70 80 20 60 200 50 Requirements Beginning 90 60 10 0 Inventory Net 0 0 0 20 Requirements Time-phased Net 20 Requirements Planned order Release Planned Deliveries Ending 60 10 0 Inventory 54 Week 4 net requirement = 20 > 0. So, an order is required. Lot-Sizing: Lot-for-Lot Period 1 2 3 4 5 6 7 8 9 10 Gross 30 50 10 20 70 80 20 60 200 50 Requirements Beginning 90 60 10 0 Inventory Net 0 0 0 20 Requirements Time-phased Net 20 Requirements Planned order 20 Release Planned 20 Deliveries Ending 60 10 0 Inventory 55 A delivery of 20 units is planned for the 4th period.. Lot-Sizing: Lot-for-Lot Exercise Period 1 2 3 4 5 6 7 8 9 10 Gross 30 50 10 20 70 80 20 60 200 50 Requirements Beginning 90 60 10 0 0 Inventory Net 0 0 0 20 70 Requirements Time-phased Net 20 Requirements Planned order 20 Release Planned 20 Deliveries Ending 60 10 0 0 Inventory 56 The net requirement of the 5th period is 70 periods. Lot-Sizing: EOQ • First, compute EOQ – Annual demand is not given. Annual demand is estimated from the known demand of 10 weeks. Estimated annual demand, Total demand over 10 weeks 52 weeks/yea r 10 30 50 10 20 70 80 20 60 200 50 52 10 590 52 10 3,068 units/year – Compute annual holding cost per unit h $0.01/unit/week $0.52/unit /year 57 Lot-Sizing: EOQ • First, compute EOQ 3,068 units/year K $10 /order h $0.52 /unit/year 2 K 2 10 3,068 EOQ 343.51 344 units h 0.52 • Therefore, whenever it will be necessary to place an order, the order size will be 344 units. This will now be shown in more detail. 58 Lot-Sizing: EOQ Period 1 2 3 4 5 6 7 8 9 10 Gross 30 50 10 20 70 80 20 60 200 50 Requirements Beginning 90 60 10 0 Inventory Net 0 0 0 20 Requirements Time-phased Net Requirements Planned order Release Planned Deliveries Ending 60 10 0 Inventory 59 Use the above table to compute ending inventory of various periods. Lot-Sizing: EOQ Period 1 2 3 4 5 6 7 8 9 10 Gross 30 50 10 20 70 80 20 60 200 50 Requirements Beginning 90 60 10 0 Inventory Net 0 0 0 20 Requirements Time-phased Net 20 Requirements Planned order Release Planned Deliveries Ending 60 10 0 Inventory 60 Week 4 net requirement = 20 > 0. So, an order is required. Lot-Sizing: EOQ Period 1 2 3 4 5 6 7 8 9 10 Gross 30 50 10 20 70 80 20 60 200 50 Requirements Beginning 90 60 10 0 Inventory Net 0 0 0 20 Requirements Time-phased Net 20 Requirements Planned order 344 Release Planned 344 Deliveries Ending 60 10 0 Inventory 61 Order size = EOQ = 344, whenever it is required to place an order. Lot-Sizing: EOQ Exercise Period 1 2 3 4 5 6 7 8 9 10 Gross 30 50 10 20 70 80 20 60 200 50 Requirements Beginning 90 60 10 0 324 Inventory Net 0 0 0 20 Requirements Time-phased Net 20 Requirements Planned order 344 Release Planned 344 Deliveries Ending 60 10 0 324 Inventory 62 Week 5 b. inv=344-20=324>70= gross req. So, no order is required. Lot-Sizing: Silver-Meal-Heuristic j rj Order for weeks 1 week, week 4 2 weeks, weeks 4 to 5 3 weeks, weeks 4 to 6 4 weeks, weeks 4 to 7 5 weeks, weeks 4 to 8 6 weeks, weeks 4 to 9 7 weeks, weeks 4 to 10 1 2 3 4 5 6 7 20 70 80 20 60 200 50 Units in the inventory at the end of Week Q 4 5 6 7 8 9 10 Per H. Ord. Period Cost Cost Cost The order is placed for K periods, for some K>0. Use the above table to find K. 63 Lot-Sizing: Silver-Meal-Heuristic j rj Order for weeks 1 week, week 4 2 weeks, weeks 4 to 5 3 weeks, weeks 4 to 6 4 weeks, weeks 4 to 7 5 weeks, weeks 4 to 8 6 weeks, weeks 4 to 9 7 weeks, weeks 4 to 10 1 2 3 4 5 6 7 20 70 80 20 60 200 50 Units in the inventory at the end of Week Q 4 5 6 7 8 9 10 20 Per H. Ord. Period Cost Cost Cost 0.00 10 10.0 If K=1, order is placed for 1 week and the order size = 20. Then, the ending inventory = inventory holding cost =0. The order cost = $10. 64 Average cost per period = (0+10)/1=$10. Lot-Sizing: Silver-Meal-Heuristic Exercise j rj Order for weeks 1 week, week 4 2 weeks, weeks 4 to 5 3 weeks, weeks 4 to 6 4 weeks, weeks 4 to 7 5 weeks, weeks 4 to 8 6 weeks, weeks 4 to 9 7 weeks, weeks 4 to 10 1 2 3 4 5 6 7 20 70 80 20 60 200 50 Units in the inventory at the end of Week Q 4 5 6 7 8 9 10 20 90 70 Per H. Ord. Period Cost Cost Cost 0.00 10 10.0 0.70 10 5.35 If K=2, order is placed for 2 weeks and the order size = 20+70=90. Then, inventory at the end of week 4 = 90-20=70 and holding cost 65 =70 0.01. = 0.70. Average cost per period = (0.70+10)/2=$5.35. Lot-Sizing: Silver-Meal-Heuristic Period 1 2 3 4 5 6 7 8 9 10 Gross 30 50 10 20 70 80 20 60 200 50 Requirements Beginning 90 60 10 0 Inventory Net 0 0 0 20 Requirements Time-phased Net Requirements Planned order Release Planned Deliveries Ending 60 10 0 Inventory 66 Use the above table to compute ending inventory of various periods. Lot-Sizing: Silver-Meal-Heuristic Exercise Period 1 2 3 4 5 6 7 8 9 10 Gross 30 50 10 20 70 80 20 60 200 50 Requirements Beginning 90 60 10 0 Inventory Net 0 0 0 20 Requirements Time-phased Net 20 Requirements Planned order Release Planned Deliveries Ending 60 10 0 Inventory 67 Week 4 net requirement = 20 > 0. So, an order is required. Lot-Sizing: Least Unit Cost j rj Order for weeks 1 week, week 4 2 weeks, weeks 4 to 5 3 weeks, weeks 4 to 6 4 weeks, weeks 4 to 7 5 weeks, weeks 4 to 8 6 weeks, weeks 4 to 9 7 weeks, weeks 4 to 10 1 2 3 4 5 6 7 20 70 80 20 60 200 50 Units in the inventory at the end of Week Q 4 5 6 7 8 9 10 H. Ord. Unit Cost Cost Cost The order is placed for K periods, for some K>0. Use the above table to find K. 68 Lot-Sizing: Least Unit Cost j rj Order for weeks 1 week, week 4 2 weeks, weeks 4 to 5 3 weeks, weeks 4 to 6 4 weeks, weeks 4 to 7 5 weeks, weeks 4 to 8 6 weeks, weeks 4 to 9 7 weeks, weeks 4 to 10 1 2 3 4 5 6 7 20 70 80 20 60 200 50 Units in the inventory at the end of Week Q 4 5 6 7 8 9 10 20 H. Ord. Unit Cost Cost Cost 0.00 10 .500 If K=1, order is placed for 1 week and the order size = 20. Then, the ending inventory = inventory holding cost =0. The order cost = $10. 69 Average cost per unit = (0+10)/20=$0.50 Lot-Sizing: Least Unit Cost Exercise j rj Order for weeks 1 week, week 4 2 weeks, weeks 4 to 5 3 weeks, weeks 4 to 6 4 weeks, weeks 4 to 7 5 weeks, weeks 4 to 8 6 weeks, weeks 4 to 9 7 weeks, weeks 4 to 10 1 2 3 4 5 6 7 20 70 80 20 60 200 50 Units in the inventory at the end of Week Q 4 5 6 7 8 9 10 20 90 70 H. Ord. Unit Cost Cost Cost 0.00 10 .500 0.70 10 .119 If K=2, order is placed for 2 weeks and the order size = 20+70=90. Then, inventory at the end of week 4 = 90-20=70 and holding cost 70 =70 0.01. = 0.70. Average cost per unit = (0.70+10)/90=$0.119. Lot-Sizing: Least Unit Cost Period 1 2 3 4 5 6 7 8 9 10 Gross 30 50 10 20 70 80 20 60 200 50 Requirements Beginning 90 60 10 0 Inventory Net 0 0 0 20 Requirements Time-phased Net Requirements Planned order Release Planned Deliveries Ending 60 10 0 Inventory 71 Use the above table to compute ending inventory of various periods. Lot-Sizing: Least Unit Cost Exercise Period 1 2 3 4 5 6 7 8 9 10 Gross 30 50 10 20 70 80 20 60 200 50 Requirements Beginning 90 60 10 0 Inventory Net 0 0 0 20 Requirements Time-phased Net 20 Requirements Planned order Release Planned Deliveries Ending 60 10 0 Inventory 72 Week 4 net requirement = 20 > 0. So, an order is required. Lot-Sizing: Part Period Balancing j rj Order for weeks 1 week, week 4 2 weeks, weeks 4 to 5 3 weeks, weeks 4 to 6 4 weeks, weeks 4 to 7 5 weeks, weeks 4 to 8 6 weeks, weeks 4 to 9 7 weeks, weeks 4 to 10 1 2 3 4 5 6 7 20 70 80 20 60 200 50 Units in the inventory at the end of Week Q 4 5 6 7 8 9 10 H. Ord. Cost Cost The order is placed for K periods, for some K>0. Use the above table to find K. 73 Diff Lot-Sizing: Part Period Balancing j rj Order for weeks 1 week, week 4 2 weeks, weeks 4 to 5 3 weeks, weeks 4 to 6 4 weeks, weeks 4 to 7 5 weeks, weeks 4 to 8 6 weeks, weeks 4 to 9 7 weeks, weeks 4 to 10 1 2 3 4 5 6 7 20 70 80 20 60 200 50 Units in the inventory at the end of Week Q 4 5 6 7 8 9 10 20 90 170 190 250 450 1 week, week 9 200 2 weeks, weeks 9 to 10 250 70 150 80 170 100 20 230 160 80 60 430 360 280 260 200 NOT COMPUTED 50 H. Ord. Cost Cost 0.00 0.70 2.30 2.90 5.30 15.30 10 10 10 10 10 10 Diff 10.0 9.30 7.70 7.10 4.70 5.30 0.00 10 10.0 0.50 10 9.50 The above computation is similar to that of the Silver-Meal heuristic. The primary difference is that the (absolute) difference between 74 holding and ordering cost is shown in the last column. Lot-Sizing: Part Period Balancing Period 1 2 3 4 5 6 7 8 9 10 Gross 30 50 10 20 70 80 20 60 200 50 Requirements Beginning 90 60 10 0 Inventory Net 0 0 0 20 Requirements Time-phased Net Requirements Planned order Release Planned Deliveries Ending 60 10 0 Inventory 75 Use the above table to compute ending inventory of various periods. Lot-Sizing: Part Period Balancing Period 1 2 3 4 5 6 7 8 9 10 Gross 30 50 10 20 70 80 20 60 200 50 Requirements Beginning 90 60 10 0 230 160 80 60 0 50 Inventory 200 Net 0 0 0 20 Requirements Time-phased Net 20 200 Requirements Planned order 250 250 Release Planned 250 250 Deliveries Ending 60 10 0 230 160 80 60 0 50 0 Inventory The computation is similar to that of the Silver-Meal heuristic. 76 Cost Comparison • Lot-for-Lot – See the last slide entitled “lot-sizing: lot-for-lot” – Number of orders: 7 – Ordering cost = 7 $10/order = $70 – Holding cost = (60+10) $0.01/unit/week = $0.70 – Total cost = 70+0.70 =$70.70 • EOQ – See the last slide entitled “lot-sizing: EOQ” – Number of orders: 2 – Ordering cost = 2 $10/order = $20 – Holding cost = (60 +10 +324 +254 +174 +154 +94 +237 +187) $0.01/unit/week = $14.94 – Total cost = 20+14.94 =$34.94 77 Cost Comparison • Silver-Meal Heuristic – See the last slide entitled “lot-sizing: Silver-Meal heuristic” – Number of orders: 2 – Ordering cost = 2 $10/order = $20 – Holding cost = (60 +10 +230 +160 +80 +60 +50) $0.01/unit/week = $6.50 – Total cost = 20+6.50 =$26.50 • Least Unit Cost – See the last slide entitled “lot-sizing: least unit cost” – Number of orders: 2 – Ordering cost = 2 $10/order = $20 – Holding cost = (60 +10 +430 +360 +280 +260 +200) $0.01/unit/week = $16.00 78 – Total cost = 20+16.00 =$36.00 Cost Comparison • Part-Period Balancing – See the last slide entitled “lot-sizing: part-period balancing” – Number of orders: 2 – Ordering cost = 2 $10/order = $20 – Holding cost = (60 +10 +230 +160 +80 +60 +50) $0.01/unit/week = $6.50 – Total cost = 20+6.50 =$26.50 • Conclusion: In this particular case, Silver-Meal heuristic and part period balancing yield the least total holding and ordering cost of $26.50 over the planning period of 10 weeks. 79 READING AND EXERCISES Lesson 9 Reading: Section 7.2-7.3 pp. 366-375 (4th Ed.), pp. 358-366 (5th Ed.) Exercise: 17 and 25 pp. 371-373, 375 (4th Ed.), pp. 363, 366 80 LESSON 10: MATERIAL REQUIREMENTS PLANNING: LOT SIZING WITH CAPACITY CONSTRAINTS Outline • Lot Sizing with Capacity Constraints – Order Partial Requirements – Checking Feasibility – Lot Shifting Technique – An Improvement Procedure 81 Lot Sizing with Capacity Constraints • In Lessons 21 and 22 we have assumed that there is no capacity constraint on production. However, often, the production capacity is limited. • In this lesson we assume that it is required to develop a production plan (i.e., production quantities of various periods) that minimizes total inventory holding and ordering costs. • Capacity constraints make the problem more realistic. • At the same time, capacity constraints make the problem difficult. 82 Lot Sizing with Capacity Constraints • We shall discuss – the lot shifting technique, a heuristic procedure that constructs a production plan, and – another procedure that improves a given production plan. • At times, capacity may be so low that it may not be possible to meet the demand of all periods. We shall discuss a procedure to check feasibility. • First, a property that is new for the problems with capacity constraints. 83 Order Partial Requirements • Recall from Lesson 22, that if a lot-sizing solution includes an order size that covers a period only partially, then we can reduce the holding cost without increasing the ordering cost. So, Silver-Meal heuristic, least unit cost and part-period balancing consider order sizes that equals demand of K periods in future, for some K>0. • As it is shown by the next example, the above does not hold if there are some capacity constraints. It may be essential to order partial requirement of a period. 84 Order Partial Requirements Example 3 Production Requirement Production Capacity June 10 12 July 10 8 • Without capacity constraint, June production quantity must include either all or none of the July production requirement – If production is ordered only in June, produce all in June – If production is ordered in both June and July, produce June requirement in June and July requirement in July 85 Order Partial Requirements • With capacity constraint, June production quantity may include a part of the July production requirement – If production is ordered only in June, produce all in June – If production is ordered in both June and July, June production quantity must include all of the June requirement and 2 units of the July requirement 86 Checking Feasibility • As it was discussed before, sometimes capacity may be so low that it may not be possible to meet the demand of all periods. • So, given demand over the planning horizon and the corresponding capacity constraints, we ask if there exists a feasible solution that meets all the demand. This is the feasibility problem. • The procedure is stated in the next slide and then the procedure is illustrated with an example. 87 Checking Feasibility • Procedure to check feasibility: – For every period, compute the cumulative requirement and the cumulative capacity. • If for every period, the cumulative capacity is larger than (or equal to) the cumulative requirement, then there exists a feasible solution. • Else, if there is a period in which cumulative capacity is smaller than the cumulative requirement, then there will be a shortage in that period, and, therefore, there is no feasible solution. 88 Checking Feasibility Example 4 Production Requirement June 10 July 14 August 15 September 16 Production Capacity 15 11 12 17 Question: Is it possible to meet the production requirements of all the months? 89 Checking Feasibility Production Production Requirement Cumulative Capacity Cumulative June 10 10 15 15 July 14 24 11 26 August 15 39 12 38 September 16 55 17 55 Answer: The August requirement cannot be met even after full production in June, July and August. Hence, it is not possible to meet the production requirements of all the months. 90 Lot Shifting Technique • Lot shifting technique constructs a feasible production plan, if there exists one or provides a proof that there is no feasible solution. • Lot shifting method is a heuristic. The production plan obtained from the lot shifting technique is not necessarily optimal. It is possible to improve the production plan. • An improvement procedure will be discussed after the discussion on the lot shifting technique. 91 Lot Shifting Technique • The lot shifting method repeatedly does the following: – Find the first period with less capacity. • If possible, back-shift the excess capacity to some prior periods. Continue. • If it is not possible to back-shift the excess capacity to some prior periods, stop. There is no feasible solution. 92 Lot Shifting Technique Example 5 Production Requirement June 10 July 14 August 15 September 16 Production Capacity 30 13 13 17 Question: Find a feasible production plan 93 Lot Shifting Technique Production Requirement June 10 July 14 August 15 September 16 Production Capacity 30 13 (less capacity) 13 17 Rule: Find the first period with less capacity. The first period with shortage is July when the capacity = 13 < 14 = production requirement. 94 Lot Shifting Technique Production Requirement June 10 July 14 13 August 15 September 16 Production Capacity 30 13 (less capacity) 13 17 July production requirement is 14 units which is 1 unit more than the capacity of 13 unit. So, this 1 unit must be produced in some earlier month. There is only one month before July. 95 Lot Shifting Technique Production Requirement June 10 11 July 14 13 August 15 September 16 Production Capacity 30 (back-shift) 13 (less capacity) 13 17 Rule: Back-shift the excess requirement to prior periods. One unit excess demand of July is back-shifted to June. So, the June production is 10+1=11 units. 96 Lot Shifting Technique Production Requirement June 10 11 July 14 13 August 15 13 September 16 Production Capacity 30 13 13 (less capacity) 17 Rule: Find the first period with less capacity 97 Lot Shifting Technique Production Requirement June 10 11 13 July 14 13 August 15 13 September 16 Production Capacity 30 (back-shift) 13 13 (less capacity) 17 Rule: Back-shift the excess requirement to prior periods 98 An Improvement Procedure • Now, a procedure will be discussed that can sometimes find an alternative production plan that may reduce the total holding and ordering cost over the planning horizon. • Keep in mind that it is guaranteed that whenever, there is an improved plan, the procedure will be able to identify that plan. Sometimes, the procedure may fail to identify an improved plan, although there may actually exist one. 99 An Improvement Procedure Example 6 Production Requirement June 13 July 13 August 13 September 16 Production Capacity 30 13 13 17 Question: Is it possible to improve the plan if K= $50, h=$2/unit/month? 100 An Improvement Procedure Production Requirement June 13 July 13 August 13 September 16 Production Capacity 30 13 13 17 Improvement procedure: Start from the last period and work backwards. In each iteration, back-shift all units of the period under consideration to one or more previous periods if additional holding cost is less than the ordering cost saved. 101 An Improvement Procedure Production Requirement June 13 July 13 August 13 September 16 Production Capacity Excess 30 17 13 0 13 0 17 1 Improvement procedure: Start from the last period and work backwards. In each iteration, back-shift all units of the period under consideration to one or more previous periods if additional holding cost is less than the ordering cost saved. 102 An Improvement Procedure Production Requirement June 13 July 13 August 13 September 16 Production Capacity Excess 30 17 13 0 13 0 17 1 Back-shift September production to June? Additional holding cost = (16)(2)(3) =$96 > 50 = K So, do not back-shift September production to June. 103 An Improvement Procedure Production Requirement June 13 July 13 August 13 September 16 Production Capacity Excess 30 17 13 0 13 0 17 1 Back-shift August production to June? Additional holding cost = (13)(2)(2) =$52 > 50 = K So, do not back-shift August production to June. 104 An Improvement Procedure Production Requirement June 13 July 13 August 13 September 16 Production Capacity Excess 30 17 13 0 13 0 17 1 Back-shift July production to June? Additional holding cost = (13)(2)(1) =$26 < 50 = K So, yes, back-shift July production to June. 105 An Improvement Procedure Production Requirement June 26 July 0 August 13 September 16 Production Capacity Excess 30 4 13 13 13 0 17 1 Final Plan The above is the result of the improvement procedure. 106 READING AND EXERCISES Lesson 10 Reading: Section 7.4 pp. 375-379 (4th Ed.), pp. 366-369 (5th Ed.) Exercise: 28 p. 380 (4th Ed.), p. 369 (5th Ed.) Lesson 11 Reading: Section 7.6 pp. 387-395 (4th Ed.) pp. 377-384 (5th Ed.) Exercise: 37 p. 395 (4th Ed.), p. 384 (5th Ed.) 107 LESSON 11: JUST-IN-TIME Outline • Just-in-Time (JIT) • Examples of Waste • Some Elements of JIT 108 Just-in-time • Producing only what is needed and when it is needed • A philosophy • An integrated management system 109 Just-in-time • Theme: eliminate all waste including the ones caused by: – inventory management – supplier selection – defective parts – scheduling of production and delivery – information system 110 Examples Of Waste • • • • • • • • • Watching a machine run Waiting for parts Counting parts Overproduction Moving parts over long distances Storing inventory Looking for tools Machine breakdown Rework 111 Some Elements Of JIT 1. 2. 3. 4. 5. 6. 7. 8. 9. Focused factory networks Grouped Technology: Cellular layouts Quality at the source Flexible resources Pull production system Kanban production control Small-lot production and purchase Quick setups Supplier networks 112 Cellular Layouts • • • • Group dissimilar machines in a cell to produce a family of parts Reduce setup time and transit time Send work in one direction through the cell (resembling a small assembly line) Adjust cycle time by changing worker paths 113 Cellular Layouts Machines Enter Worker 2 Worker 1 Worker 3 Exit Key: Product route Worker route 114 Original Process Layout Assembly 4 6 7 5 8 2 1 A 10 3 B 9 12 11 C Raw materials 115 Part Routing Matrix Parts A B C D E F G H 1 2 3 4 x x x x x x x x x x Machines 5 6 7 8 9 10 11 12 x x x x x x x x x x x x x x x x x x x x 116 Part Routing Matrix - Reordered Machines Parts 1 2 4 3 5 6 7 8 9 10 11 12 A x x x x x B x x x x C x x x D x x x x x E x x x F x x x G x x x x H x x x 117 Part Routing Matrix - Reordered Machines Parts 1 2 4 3 5 6 7 8 9 10 11 12 A x x x x x D x x x x x B x x x x C x x x E x x x F x x x G x x x x H x x x 118 Part Routing Matrix - Reordered Parts A D B C E F G H 1 x x x Machines 2 4 8 3 5 6 7 9 10 11 12 x x x x x x x x x x x x x x x x x x x x x x x x x x x 119 Part Routing Matrix - Reordered Parts A D F B C E G H 1 2 4 8 x x x x x x x x x x x Machines 3 5 6 7 9 10 11 12 x x x x x x x x x x x x x x x x x x x 120 Part Routing Matrix - Reordered Parts A D F B C E G H 1 x x x Machines 2 4 8 10 3 5 6 7 9 11 12 x x x x x x x x x x x x x x x x x x x x x x x x x x x 121 Part Routing Matrix - Reordered Parts A D F C G B E H 1 x x x Machines 2 4 8 10 3 6 9 5 7 11 12 x x x x x x x x x x x x x x x x x x x x x x x x x x x 122 Cellular Layout Solution Assembly 8 10 9 12 11 4 Cell 2 6 Cell1 Cell 3 7 2 1 Raw materials 3 A C 5 B 123 Advantages of Cellular Layouts • Reduced material handling and transit time • Reduced setup time • Reduced work-in-process inventory • Better use of human resources • Easier to control • Easier to automate 124 Disadvantages of Cellular Layouts • Inadequate part families • Poorly balanced cells • Expanded training and scheduling of workers • Increased capital investment 125 Quality At The Source • • • • • Jidoka is the authority to stop a production line Andon lights signal quality problems Undercapacity scheduling allows for planning, problem solving & maintenance Visual control makes problems visible Poka-yoke prevents defects 126 Kaizen • • • Continuous improvement Requires total employment involvement The essence of JIT is the willingness of workers to • spot quality problems, • halt production when necessary, • generate ideas for improvement, • analyze problems, and • perform different functions 127 Flexible Resources • Multifunctional workers • General purpose machines • Study operators & improve operations 128 Flexible Resources 129 Flexible Resources Cell 1 Cell 2 Worker 2 Worker 1 Worker 3 Cell 3 Cell 4 Cell 5 130 Pull Production System • • • In a push system, a schedule is prepared in advance and as soon as one process completes its work, its products are sent to the next process. In a pull system, workers take the parts or materials from the preceding stations as needed.Workers at the preceding stations may produce the next unit only after their outputs are taken by the workers in the subsequent processes. Although the concept of pull production seems simple, it can be difficult to implement. Kanbans are introduced to implement the pull system. 131 Kanban Production Control Part no.: 7412 Description: Slip rings From : Machining M-2 Box capacity 25 Box Type A Issue No. To: Assembly A-4 3/5 • A kanban is a card that indicates quantity of production • Kanbans maintain the discipline of pull production – - A production kanban authorizes production – - A withdrawal kanban authorizes the movement of 132 goods The Origin Of Kanban a. Two-bin inventory system Bin 1 Reorder Card b. Kanban Inventory System Bin 2 Kanban Q-R R Q = order quantity R = reorder point = demand during lead time 133 A Single-Kanban System 134 A Single-Card Kanban System Consider the fabrication cell that feeds two assembly lines. 1. As an assembly line needs more parts, the kanban card for those parts is taken to the receiving post and a full container of parts is removed from the storage area. 2. The receiving post accumulates cards for both assembly lines and sequences the production of replenishment parts. 135 A Dual Kanban System 136 A Two-Card System 1. When the number of tickets on the withdrawal kanban reaches a predetermined level, a worker takes these tickets to the store location. 2. The workers compares the part number on the production ordering kanban at the store with the part number on the withdrawal kanban. 3. The worker removes the production ordering kanban from the containers, places them on the production ordering kanban post, and places the withdrawal kanbans in the containers. 4. When a specified number of production ordering kanbans have accumulated, work center 1 proceeds with production. 137 5. The worker transports parts picked up at the store to work center 2 and places them in a holding area until they are required for production. 6. When the parts enter production at work center 2, the worker removes the withdrawal kanbans and places them on the withdrawal kanban post. 138 Kanban Squares X X X X X X Flow of work Flow of information Kanban Racks 407 409 410 408 411 412 Signal Kanban 407 408 409 407 408 409 Kanban Post Office 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103 104 105 106 Types Of Kanbans • • • • Kanban Square – marked area designed to hold items Signal Kanban – triangular kanban used to signal production at the previous workstation Material Kanban – used to order material in advance of a process Supplier Kanban – rotates between the factory and supplier Determining Number Of Kanbans avg.demand during lead time + safety stock No. of kanbans = container size DL w y a where – y = number of kanbans or containers – = average demand over some time period D – L = lead time to produce parts – w = safety stock, usually 10% of the demand during lead time – a = container size Kanban Calculation Example Problem statement: D = 150 bottles per hour DL = (150)(0.5) = 75 a = 25 bottles L = 30 minutes = 0.5 hours w = 10% of DL Solution: DL w 75 (0.1)( 75) y 3.3 Kanban containers a 25 Round up to 4 (allow some slack) or down to 3 (force improvement) Small-Lot Production • Requires less space & capital investment • Moves processes closer together • Makes quality problems easier to detect • Makes processes more dependent on each other 146 Small-lot Production and Purchase 147 Reducing Setup Time • • • • • • Preset desired settings Use quick fasteners Use locator pins Prevent misalignments Eliminate tools Make movements easier 148 Trends In Supplier Policies 1. Locate near to the customer 2. Use small, side loaded trucks and ship mixed loads 3. Consider establishing small warehouses near to the customer or consolidating warehouses with other suppliers 4. Use standardized containers and make deliveries according to a precise delivery schedule 5. Become a certified supplier and accept payment at regular intervals rather than upon delivery 149 Benefits Of JIT 1. 2. 3. 4. Reduced inventory Improved quality Lower costs Reduced space requirements 5. Shorter lead time 6. Increased productivity 7. 8. Greater flexibility Better relations with suppliers 9. Simplified scheduling and control activities 10. Increased capacity 11. Better use of human resources 12. More product variety 150 READING AND EXERCISES Lesson 11 Reading: Section 7.6 pp. 387-395 (4th Ed.) pp. 377-384 (5th Ed.) Exercise: 37 p. 395 (4th Ed.), p. 384 (5th Ed.) 151