Heat Transfer - Indico

advertisement

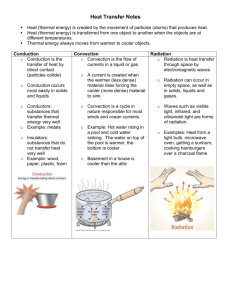

Heat Transfer G.Vandoni CERN, AT Division G.Vandoni, Heat Transfer Academic Training 2005 1 A detour in basic thermodynamics A refrigerator extracts heat at a temperature T below ambient and rejects it at a Tambient. Second law of thermodynamics : (Ta T ) W Q T W refrigeration work Q heat to extract at T and reject at Ta Minimize thermal loads: boundary temperatures fixed, heat transfer rate minimization seeked Maximize heat extraction: heat transfer rate fixed, minimize temperature difference G.Vandoni, Heat Transfer Academic Training 2005 2 The 3 modes of heat transfer Conduction: heat transported in solids or fluids at rest Q k (T ) A grad T FOURIER’s law: Convection: heat transport produced by flow of fluid Q hA(Tw T f ) Convection exchange: Radiation: heat carried by electromagnetic radiation Stefan-Boltzmann’s law: G.Vandoni, Heat Transfer Q A(Th4 Tc4 ) Academic Training 2005 3 Electrical analogy Valid in the three cases for a small DT (linearization of Stefan-Boltzmann’s law) series/parallel impedances Basis for modelling and numerization above 1D T1 Q T2 S Qk (T2 T1 ) l 1 l Rth k S V1 I I 1 Relec V2 S (V2 V1 ) l l S thermal impedance G.Vandoni, Heat Transfer Academic Training 2005 4 Cryogenic heat transfer modes PeakNucleate BoilingFlux increase of Re for decreasing T increase of Gr for decreasing T, h~T-1/2 k~T0.7 T3 G.Vandoni, Heat Transfer Academic Training 2005 5 Time-independent conduction x2 dx G x1 A( x ) 1D, constant A dT Q k (T ) A dx Th Tc Th 1 A Th Q k (T )dT L Tc Tt L A k (T )dT material' s property Tc 300 Heat flux reduction by intermediate temperature thermalization: 250 200 150 Temperature profile T(x) of st.steel bar with thermalization 2/3 of length at 80K 100 50 0 0 G.Vandoni, Heat Transfer Academic Training 2005 0.2 0.4 0.6 0.8 1 6 Intermediate heat interception Stainless steel T Th pure Copper 300 K T L A 77 K 4K Tt x x Tc Purely conductive T(x) profile over the whole length Thermalization (=fixing the temperature) at Tt Larger Q evacuated at Tt, but smaller at Tc => optimization possible with exergy function G.Vandoni, Heat Transfer Academic Training 2005 7 Thermal conductivity integrals Tc=4 K G.Vandoni, Heat Transfer Reduction of heat flow to the cold boundary temperature by thermal interception at intermediate temperature Academic Training 2005 8 Time-dependent conduction Energy conservation difference between heat entering and leaving dv T T k Q h C x x t internal heat source density dv rate of temperature increase (thermal inertia) Diffusivity D=k/C characterizes the propagation of a thermal transient… ro2 ~ D G.Vandoni, Heat Transfer …through a characteristic time depending on the object’s dimension ro Academic Training 2005 9 Diffusivity and time regimes T ro2 D x x late regime x early regime ro Late regime: exponential decay ro2 t D ro2 t D T (t ) T (To T ) exp( t ) = hS/( C V) time constant of the system 0 G.Vandoni, Heat Transfer Academic Training 2005 2 4 6 8 t 10 10 Internal versus external resistance Under some circumstances, the decay is exponential starting from t=0 Q surf A hDTs surface thermal resistance Qvol kDTvol A ro T x internal thermal resistance x hro 1 Biot number: Bi k Lumped capacitance model applies starting t=0 G.Vandoni, Heat Transfer Exponential Academic Training 2005 ro T (t ) T 11 Conductivity of solids -> form for pure and alloyed metals -> st.steel -> increase with T G.Vandoni, Heat Transfer Academic Training 2005 12 Conductivity of solids Heat carriers: phonons (k~T3) and electrons (k~T) Good electrical conductors = good thermal conductors Hinder heat transmission at low T ? (but not the best ones !) DEFECTS difference between pure and alloyed effect of modification of the defect content: magnetic impurities, annealing, cold work Hinder heat transmission at high T ? Phonon-phonon Phonon-electron no difference between pure and alloyed metals T behaviour well known G.Vandoni, Heat Transfer Academic Training 2005 13 Metal’s conductivity (T )k (T ) LLorentzT k (T ) k ( RRR, T ) Wiedemann-Franz: free-electron metal RRR parametrization (next slide) Superconductor’s conductivity Electronic above Tc, phononic below Tc: Pb: knormal/ksupra=45/T2 In : knormal/ksupra=1/T2 => Thermally switch between conducting and isolating by applying a magnetic field>critical field… G.Vandoni, Heat Transfer Academic Training 2005 14 RRR parametrization of k(T) K (W / m.K ) (W0 Wi Wio ) 1 Thermal Conductivity of copper k [W/m K] 10000 RRR RRR=80 RRR=120 RRR=180 r 0.0003 0.634 RRR W0 RRR=230 1000 (273 K ) (4 K ) T P1T P 2 Wi 1 P1P 3T ( P 2 P 4 ) e W *W i Wi 0 P 7 0 W0 W i 100 1 10 T [K] 100 1000 Valid over a broad range of RRR, ~10% exactness r P1 P2 P3 P4 P5 P6 P7 P5 T P6 0.634 / RRR / 0.0003 1.7541E-08 2.763 1.1020E+03 -0.165 70 1.756 0.838 / r0.1661 A similar parametrization also available for (RRR,T) G.Vandoni, Heat Transfer Academic Training 2005 15 Diffusivity of common materials Cv(T) decreases faster than k(T): small equilibration times at low T D=k/Cv Diffusivity larger for conductors than insulators G.Vandoni, Heat Transfer Academic Training 2005 16 Specific heat of structural materials Cv heat capacity per kg mole approximately described by the Debye function T C v 9 R q D 3 q /T 0 x 4e x dx x 2 (e 1) qD Debye temperature, a material’s property Nb: Tc/qD=0.04 G.Vandoni, Heat Transfer Academic Training 2005 17 Conductivity of gases: 2 regimes mean free path L vs wall distance L 115 molecular: p T M [Pa.s],[Pa],[cm] viscous: q proportional to p q independent from p q independent from L q=kSDT/L k predicted by kinetic theory of gases P [Pa] 10-2 100 Ar 0.63 cm 6.3 10-5 N2 1.8 1.8 10-4 He 0.60 6.0 10-5 1 2 1 8 RT k C v 3 M k~T0.7 G.Vandoni, Heat Transfer Academic Training 2005 18 Viscous regime Thermal conductivity k [Wcm-1 K-1] @ 1 atm T [K] 4He H2 N2 300 80 20 1.56 10-3 0.64 10-3 0.26 10-3 1.92 10-3 0.6 10-3 0.16 10-3 2.60 10-4 0.76 10-4 5 0.10 10-3 G.Vandoni, Heat Transfer Academic Training 2005 19 Molecular regime: Kennard’s law 1 R Q A1 1 8 Cp/Cv 1/ 2 p MT T2 T1 R ideal gas constant accomodation coefficient Q [mW/cm2] 01, degree of thermal equilibrium between molecules and wall, ~0.7-1 for heavy gases. 1.E+00 H2 He 1.E-01 1 2 N2 A 2 1 (1 2 ) 1 1.E-02 A2 for simple geometries, (parallel plates, coaxial cylinders, spheres) G.Vandoni, Heat Transfer 1.E-03 1.E-06 1.E-05 300K->77K Academic Training 2005 1.E-04 p [m m Hg] 20 Contact resistance DT RH Q / AC - phonon scattering (Kapitza) - spot-like contact points Features: G.Vandoni, Heat Transfer Temperature discontinuity at the interface: Proportional to FORCE, not to pressure (constant spot area, number of contact points increases with force) For metals, saturates above 30N @ 300K Hysteresis upon loading cycles (plastic deformations) Can be reduced by fillers, grease, In, coatings For el. conductors, Rh~Rel Rh-1=Kh increases with T then saturates Approximately proportional to microhardness/k Academic Training 2005 21 Contact resistances G.Vandoni, Heat Transfer Academic Training 2005 22 Thermal switches SCOPE: Good thermal contact for cooldown BUT Thermal insulation once cold REALIZATION: heat sink G.Vandoni, Heat Transfer Exchanger gas: long time for evacuation Gas heat exchanger: short time for evacuation Superconducting switch (Pb or In) Polycristalline graphite: k~T3 up to 100K device Switch from normal (thermally conducting) to superconducting (thermally insulating) with applied magnetic field Academic Training 2005 23 RADIATION Any surface T>0K absorbs () and emits () energy as electromagnetic radiation: depending on direction and wavelength incident P reflected P transmitted P The whole incident radiation is absorbed: =1 absorbed P Energy conservation 1 Opaque medium 1 G.Vandoni, Heat Transfer BLACK-BODY: Academic Training 2005 24 Black-body radiation Planck’s law for energy flux emitted by a cavity [W/cm3] E b , C1 5 exp( C 2 / T ) 1 Wien’s law max 2898 [ m / K ] T 300 K 10 m 80 K 36 m Integral over : Stefan-Boltzmann’s law for black body 5500 K 0.4-0.7 m (sun) (visible) G.Vandoni, Heat Transfer q T 4 =5.67 10-8 W m-2 Academic Training 2005 25 Heat exchange between two black surfaces 4 4 Q A1F12 (T2 T1 ) A1, T1, A2, T2 Geometrical FORM FACTOR F12 F12= (radiation leaving A1 intercepted by A2) / (radiation leaving A1 in all directions) = integral of solid angle under which A1 sees A2 F12 tabulated for several useful geometries G.Vandoni, Heat Transfer Academic Training 2005 26 From a blackbody to a real body Definition of (total hemispherical) emissivity 1: black-body q T 4 q T 4 real-body Monochromatic directional emissivity ( , T , ) APPROXIMATIONS I ( , T , ) I b , grey-body diffuse-body ( independent of ) ( independent of q) G.Vandoni, Heat Transfer Academic Training 2005 27 Kirchoff’s law From energy conservation in a cavity: For black-body and diffuse grey body: (T) = (T) Practical use: can be estimated from provided the incident radiation and the surface have the same temperature In reality, (,q,T) ≠ (,q,T) G.Vandoni, Heat Transfer Academic Training 2005 28 Electrical analogy for real (diffuse/grey) surfaces q12 T14 T24 q1 q2 1 1 A1 1 internal resistance of the surface to black-body emission motor q12 flux 1 A1F12 1 2 A2 2 resistance between two blackbodies T14 T24 1 1 1 1 2 A1 1 A1F12 A2 2 Blackbody form factors can be used for real diffusegrey surfaces total thermal impedance G.Vandoni, Heat Transfer Academic Training 2005 29 Heat transfer between 2 real surfaces q A112 (T24 T14 ) 12 effective emissivity (emissivities + view factor) 1 2 2 (1 2 ) 1 Parallel plates Spheres and long cylinders self-contained, not concentrical/coaxial (A1<A2) 1 2 2 A1 (1 2 ) 1 A2 A2>>A1 equivalent to A2 black: black-body radiation fills the cavity between the two surfaces and is collected by A1 proportionnally to 1 G.Vandoni, Heat Transfer Academic Training 2005 30 Emissivity and materials Real emissivities depend on direction and wavelength Drude law for ideal metal T , T 0.365 Polished metals: small Insulators: large (T): for real metals, ~T at low T Coatings: since related to surface, not bulk, resistance, => lower limit on thickness of reflectors (1 above ~40nm) G.Vandoni, Heat Transfer Academic Training 2005 31 Emissivity and materials –2- G.Vandoni, Heat Transfer Academic Training 2005 32 Radiative heat transfer in cryogenics 4 4 q (Twarm Tcold ) Blackbody radiation from 290 K to 80 K: 399 W/m2 Blackbody radiation from 290 K to 4.2 K : 401 W/m2 negligible effect of Tcold Blackbody radiation from 290 K to 4.2 K: 401 W/m2 Blackbody radiation from 80 K to 4.2 K : 2.3 W/m2 reduction of heat flux by one cooled screen G.Vandoni, Heat Transfer Academic Training 2005 33 Floating radiation screens Floating = not actively cooled, they operate at a temperature determined by heat balance Tw Tc 4 4 (Tw Tc ) q 2 T 1 4 4 q (Tw Tc ) 2 2 1 4 4 q (Tw Tc ) n 1 2 1 4 T (Tw Tc4 ) 2 4 4 4 T T 4 c Ti Tc4 w i 1 n G.Vandoni, Heat Transfer Academic Training 2005 34 Multi-layer Insulation Stacking of “reflectors” separated by insulating “spacers” reflector spacer blanket Reflector: low emittance radiation shield polyester film, 300-400 A pure Al coating, usually double face Spacer: insulating, lightweight material paper, silk, polyester net 1. Heat transfer parallel to the layers ~1000 times greater than normal to the layers thermal coupling between blanket edges and construction elements may dominate heat rate. 2. Heat transfer very sensitive to layer density single local compression affects the T profile over the entire blanket, substantially degradating heat loss (factors 2-3 more !) G.Vandoni, Heat Transfer Academic Training 2005 35 Effective conductivity k=aT+ bT3 Heat transfer rate q=k/e DT, e = thickness W/m2 MLI: effective conductivity Optimal density: 10-20 cm-1 layers/cm Low boundary temperature: 77 K-> 4K High boundary temperature: 300 K-> 77K G.Vandoni, Heat Transfer heat transfer rate determined by aT, not by radiation 1 single aluminized foil is sufficient in high vacuum in bad vacuum, MLI provides sufficient insulation heat transfer rate determined by radiation important reduction with layer’s number bad vacuum: radiation dominates anyway Academic Training 2005 36 MLI: number of layers 30 layers, 300K-> 77K, 0.5 W/m2 10 layers, 77K-> 4K, 20 mW/m2 N = 15 cm-1 Tc= 4.2K, = 0.03 G.Vandoni, Heat Transfer Academic Training 2005 37 MLI and residual pressure MLI constitutes a supplementary protection against vacuum rupture, only at low boundary temperature: at high boundary temperature, radiation dominates anyway interstitial gas: nitrogen 300 K -> 77 K 77 K -> 4.2 K 300 K -> 77 K 77 K -> 4.2 K 300 K -> 77 K 77 K -> 4.2 K 300 K -> 77 K 77 K -> 4.2 K Kennard’s law G.Vandoni, Heat Transfer Academic Training 2005 38 Passive cooling by radiators Radiation cooling to a cold screen -> cool down without contact Requires large surface-to-volume ratio + large emissivity Black silicon paints compatible with high vacuum from the space industry (cooling of CERN antiproton collector’s mobile electrodes) Cooling in space applications towards the cosmic background radiation at 2.7K Figure: the NGST (next generation space telescope) solar screen G.Vandoni, Heat Transfer Academic Training 2005 39 Free and forced CONVECTION Q / A q h(Ts T f ) Q transferred heat, A surface area h: heat transfer coefficient, function of fluid properties, flow velocity and channel geometry Scope: determine h Tf Ts Analysis: dimensionless groups, EMPIRICAL correlations Free (natural) convection : the fluid movement is due to expansion upon heating, reduction of density and buoyancy (kettle, fireplace) Forced convection: the fluid is set into movement by external action (pressure difference, mechanical action, elevation difference) G.Vandoni, Heat Transfer Academic Training 2005 40 Convection exchange coefficient Boiling, water q h(Ts T f ) Boiling organic liquids Convective heat transfer in cryogenic fluids not different from any other, except He II Condensation, water vapors Condensation, organic vapors Liquid metals, forced convection Boiling HeI, N2 peak nucleate flux (PNBF): 104 W/m2K Water, forced convection Organic liquids, forced convection Gases 200atm, forced convection Gases 1atm, forced convection Gases, natural convection 1 G.Vandoni, Heat Transfer 10 102 103 h (W/m2K) Academic Training 2005 104 105 106 41 Dimensionless groups Group Name Re Reynolds Pr flow character Prandtl fluid characteristics Nu Nusselt Definition Physical interpretation Vd / inertia force/viscous force C p / k momentum transport/ thermal diffusivity hd / k convection exchange/ conduction exchange defines convection exchange Gr Grashof Ra Rayleigh gDTd 3 2 / 2 buoyancy force/viscous force like Re for free convection Gr Pr d=characteristic dimension, ex. tube diameter or hydraulic diameter, =dynamic viscosity, =volume expansivity, k=thermal conductivity, DT=temperature difference, =density, Cp=specific heat at constant pressure, h=heat transfer coeff , g= gravity acceleration G.Vandoni, Heat Transfer Academic Training 2005 42 Reynolds number and flow character Re Vd density, V fluid average velocity, d hydraulic diameter, dynamic viscosity Inertia forces compared to viscous forces Viscous forces are stabilizing: Inertial forces are de-stabilizing: laminar flow turbulent flow Laminar: low heat transfer coefficient Turbulent: high heat transfer coefficient In free convection, Gr plays the role of Re: buoyancy versus viscosity G.Vandoni, Heat Transfer Academic Training 2005 43 Free (natural) convection General relation Nu = function(Gr,Pr) Nu = a (Gr .Pr) n= a . Ra n Configuration regime limits a n vertical, free surface laminar turbulent 5.103<Ra<109 109<Ra<1013 0.59 0.13 ¼ 1/3 Ra<103 1.18 1/8 laminar 103<Ra<2.107 0.54 ¼ turbulent 2.107<Ra<1013 0.14 1/3 Empirical form horizontal, free surface d to be used to calculate: diameter (horizontal cylinder), height (vertical plates/cylinders), smallest exchange dimension (horizontal plates), distance between walls (enclosures) G.Vandoni, Heat Transfer Academic Training 2005 44 Free convection in gases and air common gases: h~p½, important increase at low temperature h~T-½. cold helium gas (80K, 1 bar): Nu~3.65 (laminar) Air close to ambient conditions vertical plates DT h 1.4 d horizontal plates DT h 1 .3 d G.Vandoni, Heat Transfer 1/ 4 Watt m-2 K-1 1/ 4 Academic Training 2005 Watt m-2 K-1 45 1phase forced convection Empirical relation Nu = f (Re,Pr) = aF Rem Prn Configuration regime limit a m n F horizontal plate laminar 103<Re<105 0.66 ½ 1/3 1 turbulent 3 105<Re 0.036 0.8 1/3 1 103<Re<2.1 103 Re Pr D/L >10 1.86 1/3 1/3 (D/L)1/3 Re Pr D/L >10 RePrD/L>2.4 105 0.023 0.8 0.33 1+(D/L)0.7 horizontal tube laminar annular space turbulent Colburn formula Sieder & Tate formula G.Vandoni, Heat Transfer Academic Training 2005 46 Steps to solve a convection problem 1. Calulate Re to determine flow character: laminar/turbulent hydraulic calculation of pressure drop dp v 2 4 f f=Fanning, function of Re dx 2 d 2. Evaluate Pr (fluid characteristics) 3. 4. Choose the appropriate formula for Nu -> h In doubt about the importance of free convection: calculate Gr G.Vandoni, Heat Transfer Academic Training 2005 47 Boiling heat transfer in He I Increase of heat transfer up to a Peak Nucleate Boiling Flux: He I: 1 W cm-2 @ 1K superheat N2 : 10 W cm-2 @ 10K H2O: 100 W cm-2 @ 30K Hysteresis: cooling path not the same as warming path Positive consequence for safety: limit to the highest flux released by a warm object (quenching magnet, human skin) G.Vandoni, Heat Transfer Academic Training 2005 48 Two-phase convection heat transfer = bubble formation and motion near the walls + direct sweeping of the heated surface by the fluid Instabilities of density-wave type: pressure waves increase locally the heat transfer rate, the fluid expands => decrease in conductivity and heat transfer rate How to avoid them: -Maintain low vapor quality -Not too large differences in elevation -No downstream flow restrictions -Introduce upstream flow restrictions G.Vandoni, Heat Transfer Academic Training 2005 -> destabilizing -> stabilizing 49 Refrigeration properties of cryogens Working domain close to critical point: properties of liquid and vapor phase are similar low vaporization heat Low viscosity hence excellent leaktightness required for He He N2 H2O Normal boiling point 4.2 77 373 Critical temperature 5.2 126 647 Critical pressure 2.3 34 221 Liquid density/ Vapor density* Heat of vaporization * 7.4 175 1600 [Jg-1] 20.4 199 2260 Liquid viscosity * [poise] 3.2 152 283 Enthalpy increase between T1 and T2 T1 = 4.2 K T2 = 77 K 384 - - T1 = 4.2 K 1157 - T2 = 300 K *at normal boiling point G.Vandoni, Heat Transfer 228 highly effective for selfsustained vapor cooling! Academic Training 2005 50 Shielding potential of cold vapours Pure conduction heat losses evacuated at the coldest temperature Self sustained vapour cooling: vapour flow generated only by heat leak is used to cool the device Th L A Tc A T2 Q k (T )dT L T1 G.Vandoni, Heat Transfer Heat evacuation across a small DT thermodynamically much more efficient Academic Training 2005 51 Shielding potential of cold vapours heat balance, perfect exchange k (T ) A dT Q k (T ) A m C p (T Tl ) dx dT m C p (T Tl ) dx self-sustained evaporation of fluid Q m L v Tl A T2 k (T )dT Q L Tl 1 (T Tl )C p / Lv Q A T2 Q k (T )dT L l Th.conductivity integral [W cm-1] [W cm-1] ETP copper OFHC copper 128 110 1620 1520 Aluminium 1100 39.9 728 AISI 300 st.steel 0.92 30.6 G.Vandoni, Heat Transfer Academic Training 2005 52 Phase diagram of helium FORCED FLOW small inventory, no instability bi-variant, high p, JT heating POOL BOILING constant T, irrespective of q PNBF, large quantities of cryogen FORCED FLOW JT cooling, good heat transfer, small liquid inventory flow instabilities, small (p,T) range high HT, low T, large Cv refrigeration cost, sub-atm pipes high HT, low T dielectric breakdown, sub atm, large gas volume G.Vandoni, Heat Transfer Academic Training 2005 53 Typical heat inleaks in a cryostat …between flat plates, at vanishingly low temperature [W/m2] Black-body radiation from 290 K 400 Black-body radiation from 80 K 2.3 Residual gas conduction (100mPa helium) from 290 K 19 Residual gas conduction (1mPa helium) from 290 K 0.19 Multi-layer insulation (30 layers) from 290 K, residual pressure below 1mPa Multi-layer insulation (10 layers) from 80 K, residual pressure below 1mPa 0.5-1.5 Multi-layer insulation (10 layers) from 80 K, residual pressure 100mPa 0.2 0.05 Radiation screening Insulation vacuum MLI at high (>30 layers) and low (10 layers) boundary temperature G.Vandoni, Heat Transfer Academic Training 2005 54 Heat inleaks in an accelerator Cryostat heat inleak Resistive dissipation Beam-induced losses radiation to cold surface superconductor splices synchrotron radiation cold mass supports wall resistance beam-image currents warm-to-cold feedthroughs instrumentation beam-gas inelastic scattering AC losses beam losses G.Vandoni, Heat Transfer Academic Training 2005 55