ACARP Sept 07 Presentation

advertisement

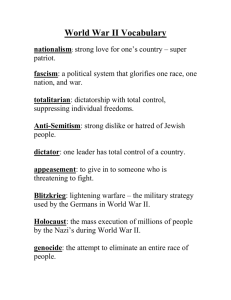

Beltana Development ACARP Roadway Development Operators Workshop Sept. 2007 16 Beltana Hunter Valley NSW 17 Beltana 18 Blakefield South 19 Blakefield South 20 Beltana Development Beltana Update. Blakefield Update. USA Systems Study. Supporting a High Capacity Longwall. 21 Beltana Total of 28 Million tonnes mined to date. Total of 80 km of roadway driveage to date. 22 Beltana 2007 Total of 5.5 Million tonnes mined to date. Total of 16.5 km of roadway driveage to date. 23 Single or Super Single Miner MG7 V’s Super Unit MG8 MG9 Cut Rate m/hr 4.2 4.9 5.6 Metres/wk 340 389 373 Belt Moves 17.8 17.6 19.9 24 Single or Super Single Miner MG7 V’s Super Unit MG8 MG9 Eng Avail. 91.8 93.8 88 Op Avail. 77.6 74.9 75.4 Op Time. 78 74.8 67 25 Single or Super Single Miner MG7 V’s Super Unit MG8 MG9 3.6 3.4 3.5 Total Metres 7,421 6,555 7,045 Days / Panel 159 114 132 Pillar Cycle 26 Single or Super Single Miner v’s Super Unit Gains – Cut Rate 112% – Metres / Week 125% – Pillar Cycles 103% – Days / Panel 119% 27 Single or Super Single Miner v’s Super Unit Losses – Maint Quality – Standards – Belt Moves / Parallel Tasks – Production Maintenance. – Sustainability 28 Changes at Beltana Back into Mains Driveage Starting a 2nd Crew – Self Hired – Integration of Crews Change in Development Structure – Addition to Development Management Team – Each Crew self sufficient – Maintain Single Panel Focus. 29 Single Miner What will it support at Beltana Development at 340m per week Equates to 144m LW retreat / wk Equates to 165,600t / wk 6.95 Million Tonnes / yr 30 Strategies Key Points to our Strategies – Manning. – Standards. – Measurement. – Continuous Improvement. – Fit for purpose equipment. – Communication. 31 Blakefield South 173km of Driveage 44.6 million ROM tonnes 400m Longwall Face 6.7 million Tonnes / Year 9 year Life 32 Blakefield South Up to 10m3/t if insitu CH4 High volumetric capacity ventilation system maximum 580m3/sec. Force–exhaust (pressure balanced) ventilation system. 7 heading mains / 3 heading gate roads. 33 Blakefield South 34 Blakefield South 35 USA System Study Review Strategies for future Development systems. – Review 3 Hdg Gate Road Development. – Review Continuous Haulage. – New Technology. 36 Mines Visited Peabody Highland – FCT in Room and Pillar Operation. (High Voltage Miners.) Consol Loveridge – 3 Hdg Development and changing from batch Haulage to FCT. (ABM’s.) Cumberland – 3 Hdg Development. (Miner Bolters and Mobile Bolters.) 37 Mines Visited Twenty Mile – 3 Hdg Development (Place Changing.) – High Producing Mine. San Juan – 3 Hdg Development (place Changing.) – Good Technology. Joy Franklin – New Technology ED miners, Automatic Drill Rigs and FCT’s. 38 San Juan Transport 39 Specialise The Americans Specialise everything they do. Whether it be in Motels, Restaurants, Roadwork's and Coal Mining. 40 Development Place Changing – Up to 8,200ft / mth = 2,500m / mth Bolter Miners – Up to 6000ft / mth = 1830m / mth FCT Operation Room and Pillar – Up to 700ft / shift = 210m / Shift – 21m / hr (Approx 8,500m / mth) 41 3 hdg Development Opportunities Design FCT Operation (Consol Loveridge) – ABM 14’s – Joy 4 FCT – Auxiliary Ventilation To give a 50% improvement in Gate Road Development. Process Cost Saving Up to 9000ft / Month = 2,750m / Month 42 Where we are at Now Beltana Bolter Miner – Joy 12CM12 – 2 Joy 10SC32 Shuttle Cars (16t) – Breaker Feeder (18t bunker capacity at 1700tphr) – Auxiliary Ventilation – 5.5m/hr Up to 6200ft / mth = 1888m / mth 43 Development Where does Development need to be? What maximum production can we expect from a single Longwall? 44 Some Facts 7million tonne Longwall (400m face at 1740 t/m) – 2hdg Development – 3hdg Development 2.88m/hr 4.51m/hr 10million tonne Longwall – 2hdg Development – 3hdg Development 4.11m/hr 6.44m/hr 45 Some Facts 12million tonne Longwall – 2hdg Development – 3hdg Development 4.93m/hr 7.73m/hr 15million tonne Longwall – 2hdg Development – 3hdg Development 6.17m/hr 9.67m/hr 46 Low Hanging Fruit Obtained Process Improvement Old 7.2 Day Pillar Cycle New 3.6 Day Pillar Cycle Total Process Improvement 100 % 47 FCT Model For Beltana From Data measured at Beltana a Cut Rate after a belt move of 8.92 m/hr can be achieved. Joy FCT Modelled a rate 8.98 m/hr with a Joy 12CM12D. Therefore we believe an average cut rate with an FCT for a 100m pillar cycle would be in the order of 8 to 9m/hr. This would be a 70% increase in this part of the Process. 48 Opportunities Bolter Miners – 14ED25 being built in USA to go into Consol McElroy which commenced production 1st May 2007. – ABM 25’s Used throughout QLD and NSW Automated bolting Self Drilling Bolt 49 Opportunities Continuous Haulage Systems – Joy4FCT – Stamler Chain Haulage – Prairie System – Sandvik Continuous Haulage 50 FCT Stats 51 Summary To Advance to the next step in Longwall Production Development has to do something different. By 3 to 5 years time we need to have developed a new system so Longwall Coal is not restricted. 52 Development Can’t keep doing the same and expect something different. 12 Million Tonne Longwalls being supported by 500 people. This is not sustainable. 53 USA is BIG 54