File

advertisement

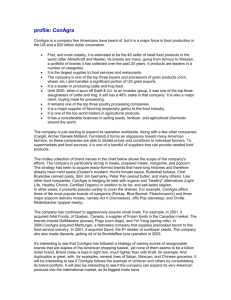

Introduction ConAgra Foods is a $12 billion company headquartered in Omaha, Nebraska. The company employs approximately 25,000 people in North America. ConAgra is a major company within the food processing and production industry. Food processing and production encompasses the procurement of harvested crops and butchered animal products in order to produce attractive and marketable long shelf-life food products. ConAgra maintains a large profile of brands that spreads across two business segments, consumer food products and commercial food products. ConAgra brands for consumer foods include Healthy Choice, Hunts, Snack Pack and many more. Consumer food brands are mainly carried by grocery and convenience stores. While commercial food product brands main customers are restaurants. Commercial food brands under ConAgra include Lamb Weston, Spicetec and others. One reason why ConAgra has such an interesting supply chain is that their products for different business segments serve customers that both require different distribution channels. Major competitors for ConAgra include Kraft, General mills and Cargill. In 2012 ConAgra ranked 14th in the food processing industry slightly below General Mills and one position above Cargill. Although according to standard supply chain metrics ConAgra is performing below industry average, their innovation in new product delivery, advanced inventory system, environmentally conscientious logistics planning and socially responsible supply chain practices all help to make ConAgra a strong player in the food processing and production industry. Supply Chain Metrics Examining ConAgra based on Supply Chain Metrics and drawing comparisons between ConAgra, leading competitors as well as the industry average allows for a holistic performance analysis of ConAgra’s supply chain After examining the supply chain metrics for ConAgra, General Mills, and Kraft. (Appendix 1). ConAgra has its strengths and weaknesses. Some of the weaknesses ConAgra has is its PM, ROA, ROE, and Inventory Turnover. A weakness in all these areas can mean different things. A PM problem can mean they aren’t as effective and efficient at making sales. A problem with ROA can mean they aren’t as effective at getting a good return on the assets they have. An issue with ROE means they aren’t as diligent with the owners money to invest in. A problem with inventory turnover can mean they have too much inventory, or bad sales, or something along those lines. A possible explanation for this is that they are offering higher quality brands and lower prices, which can dampen all of those ratios. For ConAgra’s strengths can include Debt to Equity and Current Ratio. Compared to General Mills and Kraft, ConAgra is a lot more liquid. They could more easily pay their liabilities if they all came do. ConAgra’s debt to equity is better than Kraft’s but worse then compared to General Mills. ConAgra is more leveraged compared to General Mills but not to Kraft. Which means they are operating on more debt than General Mills is but less so compared to Kraft. For the higher debt to equity it depends on what ConAgra is doing. If they are changing processes, reinvesting it to generate more revenue, etc, that is a good thing. However, if they are paying back old debt and not using it wisely then it can be a problem. With there other weaker ratios it can be problematic to have a higher debt to equity such as in this case. Distribution Channels ConAgra has two possible scenarios for their distribution network. Both scenarios include distribution centers with different methods of arriving to the customer. The final shipping method depends on the product and the intended use of the product. ConAgra’s main distribution channel is a distributor storage with customer pickup type system. This distribution channel is mainly for ConAgra products that are intended for retail which includes brands like Marie Callender's and Healthy Choice. Each factory produces a specific type of product (Chef Boyardee, Slim Jim, ect.) and then the products are shipped internationally to distribution centers in which the orders are filled for retail locations. In this case the retail locations are mainly grocery stores (Walmart, local grocery stores, etc.) or convenience stores (Seven-Eleven, Maverick, etc.). For more popular products that require greater supply chain responsiveness due to faster turnover ConAgra may adjust the distribution channel and ship to Walmart or Seven Eleven distribution centers. Product is then distributed to the individual retail locations. These retail locations act as pick-up sites in which the customers pick-up and pay for their products. The next scenario is distributor storage with carrier delivery. This distribution channel scenario is predominantly used for ConAgra’s Commercial Food products. For instance, the Lamb Weston brand division under ConAgra provides potato products for Arby’s as well as many other fast food chains. The Lamb Weston plant produces the potato products which are shipped to distribution centers across North America. From the distribution center 3rd party carriers deliver the product to Arby’s locations and other fast food locations. From the fast food restaurants products are delivered to the end consumer. New Product Launching ConAgra Foods is a major industry player in food processing and production. By evaluating ConAgra’s consumer foods segment their market presence in food processing and production is apparent. ConAgra products can be found in an astonishing 97 percent of American households, and sells nearly 13 million packages of food products per day. ConAgra’s other major business segment is the commercial food industry which accounts for 35% of annual sales. Within the commercial food industry ConAgra has several brands devoted to different successful types of products. Brands include Lamb Weston, ConAgra Mills, Ultra grains, Spicetec and JM Swank. Having several well established brands within ConAgra allows for a more extensive and diversified product portfolio. ConAgra has a research and development team which develops products for all brands and businesses across the company. The Research Quality and Innovation Team (RQI) is extensive considering ConAgra’s expansive product portfolio. The team brings together innovative employees from various specialized segments across ConAgra. The main products that the RQI team focuses on is consumer food products across all ConAgra consumer food brands. The team has a set procedure they follow to ensure that the environment is fit to encourage innovation since ConAgra works to instill an innovative culture. RQI has close partnerships with each business and operating group within ConAgra. These partnerships aid RQI in building a strong communication network among businesses and operating groups. Strong communication among partners enables RQI to prioritize innovation and allows them to deliver products that address the needs of their customers as well as make a market impact that satisfies ConAgra executives. Some evidence that the RQI team innovation process is delivering successful results is that in 2011 two products designed by the RQI team received Edison Innovation Awards, which are given each year to innovative new products. They received one for their ‘Healthy Choice Top Chef Café Steamers’ and one for their ‘Marie Callender’s Bakes.’ Head of the RQI team is Al Bolles, executive vice president of research, quality and innovation, says his management style promotes employees with ideas to take risks and own their products. He says that communication throughout the company and making folks accountable for their actions leads them to have empowerment which will lead to innovation. He also says that, “Innovation is our lightning rod for growth.” Bolles also states,“We exist to drive the business; the business isn’t here to fund our science projects. We’re here to use science and technology to find better ways of making better products.” Strong research and development allows ConAgra to maintain customers interest yet product roll out and delivery is key in order for customers to access products. Therefore supply chain ability plays an important role in allowing for successful new product launches. New product launching involves the whole supply chain from the very beginning. There are cross-functional teams in each subsidiary company of ConAgra who help with design and implementation of new products. Customer input is a highly valued piece of information for ConAgra, as Bolles states, “Ideas start with consumer insights.” Bolles says there is a lot of work which goes into these projects and new product ideas outside of work which is what really makes a difference. Having these empowered team members in a culture which allows them to thrive and turn their ideas into exciting new products, helps to drive innovation along the supply chain for ConAgra Foods. (Troops, Food Processing, 2013). Logistics Systems ConAgra is dedicated to lowering their carbon footprint in every process from the farm to the dinner table, and especially in their logistics system. ConAgra contracts 95 percent of their transportation, and have come up with a sustainable transportation strategy. This strategy is made up of three parts consisting of capacity utilization, utilizing most efficient transportation modes, and exploration of alternative fuels. For capacity utilization, ConAgra has developed a new pallet initiative that changes the shapes and sizes of packages to match the type of transportation they will use. This means more products on each trip, which leads to less trips and less carbon emissions. This project has cut greenhouse gas emissions by more than 3,900 metric tons over the last four years. ConAgra has also experimented with different types of transportation to find the most efficient way to move products. Trucking still makes up about 84 percent of total transportation, but railroad at 9.4 percent and container transportation at 4.7 percent are on the rise. ConAgra is also looking at ways to use less diesel fuel and has been exploring with alternative fuels such as biodiesel and vegetable oil that produce less harmful emissions. By actively moving toward more sustainable logistics systems ConAgra could ultimately increase stakeholder satisfaction and grow their customer base. Industry players within the commercial food industry are often chastised for having a lack of concern for environmental conscientiousness. ConAgra’s dedication to best sustainable practices can help them to maintain a competitive edge within the industry. By focusing on sustainability within ConAgra’s logistical system a higher value will be associated with their products for customers and potential customers that prefer environmentally friendly products. This could ultimately aid ConAgra in increasing market share. Inventory ConAgra’s current inventory system begins with working with their customers to clarify the customers’ needs, and develop a unique set of customer focused programs to assist in managing their business. To provide what customers want, ConAgra offers customers, display ready units for special promotions or events that arrive ready to be displayed instantly. However, other customers may want to pick up their product at a plant or mixing center depending on the type of product as well as the type of customer. At various locations ConAgra is able to keep the product at ideal temperatures due to their network of dry and temperature controlled facilities to maintain freshness. The mixing centers are located conveniently around major stores and distribution centers to reduce miles shipped and delivery costs while increasing responsiveness. ConAgra uses vendor-managed inventory to support their customer-centric philosophy. By using vendor-managed inventory, ConAgra manages the ordering process at the distribution-center level and holds themselves accountable for customers’ key metrics such as days on hand, inventory turns, and the in-stock rate. ConAgra can identify costs and order history for each product SKU to identify improvements in order efficiency. ConAgra then uses warehouse and store-level inventory and sales data to help customers identify when items need to be replenished. To improve upon their current inventory system, ConAgra could employ a couple of options. Currently, ConAgra keeps customers’ food items at ideal temperatures before shipping them, or waiting for pickup. However, ConAgra could use trucks that transport goods at the same ideal temperatures, to improve product quality, customer satisfaction and reduce the spoilage rate of their products. Also, the trucks would allow shipments to deliver products at locations further away since the products will be kept fresh. Another option ConAgra could use to improve their inventory management system is to continuously improve on inventory optimization using data. Senior Director Asis Sengupta at ConAgra gives insight into how his company may improve, “mastering data cleansing and maintenance from end-to-end interfacing with our facilities to manage inputs and monitor results. Creating a resourcing and/or research team to ensure implementation would be a key driver behind success of this.” With the vendormanaged inventory model ConAgra will want to use this data to increase profits for themselves, and their retailers by having the right demand and customer data. In 2006 ConAgra restructured their inventory management system from 11 different systems to a single integrated application suite. ConAgra implemented the SAP enterprise inventory optimization application by SmartOps. The application helped to smooth out the inventory process and reduce redundancy in inventory information storage. Since the implementation of the new system ConAgra has experienced many improvements in inventory management. Financially, ConAgra has lowered days of finished goods inventory by 20% and has reduced transportation expediting costs. Operationally, store-in-stock rate has increased by 0.7%, forecast accuracy has increased by 30% and case-fill on-time rate has increased by 0.3%. Strategically, ConAgra has increased customer satisfaction, boosted capacity planning and increased productivity by automating manual processes. Supply Chain Ethics ConAgra has a strong focus on ethical supply chain practices. From implementing sustainable best practices into their logistics system to procuring products from suppliers that provide high quality products ConAgra applies ethical practices across many supply chain facets. In order to promote sustainable long-term business success ConAgra promotes sustainable practices into their supply chain. For instance ConAgra is committed to lowering greenhouse gas emissions. ConAgra joined the Carbon Disclosure Project’s Supply Chain Leadership Council in 2009 to encourage accountability and disclosure practices with emission reduction targets. To accomplish this ConAgra requested more than seventy of their top suppliers and contract manufacturers to release their information related to their own greenhouse gas emissions in order to collaborate efforts into the future. One way that ConAgra is procuring sustainable raw material is by using palm oil that was produced sustainably. ConAgra’s goal is for one hundred percent of ConAgra’s palm oil to be RSPO sustainability certified by 2015. Successful goal completion will result in a sustainable market, and help prevent deforestation of lands. Another way that ConAgra is procuring ethical raw materials is by pledging to eliminate the use of pork from gestation crates from their supply chain. Gestation crates measure about two by seven feet which is too small for sows to turn around. By 2017 ConAgra expects all suppliers for their Slim Jim beef jerky and Hebrew National hot dogs to produce action plans for eliminating gestation crates. ConAgra is also demanding suppliers to create systems within their operations that allow the humane origins of their pork to be traceable. ConAgra expects this to be a long term process that could take up to ten years. By reducing greenhouse gas emissions ConAgra can build a more cost efficient and sustainable supply chain. Building sustainable products into ConAgra’s supply chain such as sustainably produced palm oil shows ConAgra’s commitment to the environment and a healthy future. Also by eliminating gestation crate pork products from ConAgra’s supply chain exemplifies strong corporate social responsibility and increases stakeholder satisfaction. Implementation of strong supply chain ethics will help ConAgra to build goodwill among customers in order to tap a new market segment and stimulate demand. Conclusion ConAgra is a company that exemplifies how innovation in supply chain can lead to ultimate business success. By setting up responsive distribution channels to serve key customers, introducing innovative new products, and using sustainable logistic systems ConAgra has kept their customer-centric philosophy. Combining ConAgra’s customer-centric philosophy with effective inventory systems, and employing strong business ethics has enabled ConAgra to become a nationwide leader in supply chain management. Appendix ConAgra Profit Margin: 3.48 ROA: 3.99 ROE: 9.87 Current Ratio: 1.50 Debt to Equity: 2.10 Inventory Turnover: 4.99 General Mills ROA: 8.27 ROE: 22.14 Inventory Turnover: 6.63 Profit Margin: 10.41 Debt to Equity: 1.14 Current Ratio: 1.02 Kraft ROA: 7.92 ROE: 16.92 Inventory Turnover: 6.46 Profit Margin: 8.95 Debt to Equity: 2.66 Current Ratio: 1.34 Industry PM: 6.3 ROA: 7.5 ROE: 15.90 Current Ratio: 1.75 Debt to Equity: .50 Inventory Turnover: 6.2 Sources: Troops, D. (2004, 15). Food Processing. 2012 R&D Team Winner: ConAgra. Retrieved May 02, 2013, from http://www.foodprocessing.com/articles/2012/rd-conagra.html Turner, T., Maxwell, J., McPartlin, S., Weizmann, B., & Dugal, L. (2011, 25). Grocery Manufacturers Association | GMA. 2010 Food, Beverage, and Consumer Products Financial Performance Report. Retrieved April 25, 2013, from http://www.gmaonline.org/downloads/wygwam/LA-100348_2010_CPG_Report_2010_Final_SinglePages_Interactive_v2.pdf (n.d.). Retrieved from http://finance.yahoo.com http://finance.yahoo.com (2013, 15). Yahoo Finance. Industry Browser. Retrieved April 20, 2013, from http://biz.yahoo.com/p/340conameu.html Dunkin' Donuts. N.p.: Environmental Leader, 2012. N. pag. Web. 5 May 2013. <http://www.environmentalleader.com/2012/09/27/dunkin-donuts-conagra-foods-make-humanesupply-chain-commitments/>. Food Processor. N.p.: Putnam Media, 2003-2014. N. pag. Web. 4 May 2013. <http://www.foodprocessing.com/top100/>. Con Agra. N.p.: n.p., n.d. N. pag. Web. 4 May 2013. <http://www.conagrafoods.com/pdf/We_Know_How.pdf>. "2012 Citizenship Report." Transportation. N.p., n.d. Web. 12 Apr. 2013. <www.conagrafoodscitizenship.com/good-for-the-planet/our-climate-strategy/transportation/>.