Diverting C&D Wood to Fiberboard Opportunities for Massachusetts

advertisement

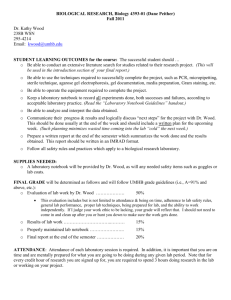

Diverting C&D Wood to Fiberboard Opportunities for Massachusetts Sylvain Martel Wood supply manager Who are we? Tafisa Canada Tafisa Canada Overview • Member of Sonae Industria, based in Portugal • Largest multi-regional composite panel producer globally. • Mill began operations in 1992 • Major expansion in 2000: 2nd Particleboard line (being rebuilt in 2007) • 325 employees • Product line: Particleboard and Melamine surface board • Largest integrated Particleboard plant in North America • 2 Particleboard Continuous Presses, 9’ and 10’ widths • 4 Melamine Presses Tafisa Canada Tafisa Canada Overview • ISO 9001 manufacturing certification • ISO 14001 environment certification (1st in North America) • EPP certified by the Composite Panel Association • 92% Recycled and Recovered wood fibre •FSC certified • Have made capital investment to process « urban wood residues » within strict physical quality parameters. Tafisa Canada Montreal 140 miles TC Boston 275 miles Plant Location in relation to Boston MA and Montreal QC The grey shaded region denotes Tafisa’s natural market for Particleboard & Melamine panels. Massachusetts and New England are in the “heart” of our market. Tafisa Canada • New England represents an important market for Tafisa. • We ship $7 million worth Particleboard and Melamine panels per year to Massachusetts and New England. • With the rebuild of our Particleboard Line 2, we expect to build substantially on this volume in 2008. • Our volume in New England is sold primarily through Distributors such as Baer Supply Company , North Pacific Corporation and other valuable customers. • Our products are used primarily to manufacture Kitchen & Bathroom Cabinets, Interior (Walk-In) Closets, Residential and Office Furniture, Kitchen & Retail Countertops. • Our New England customer base would widely embrace the concept of Tafisa purchasing « urban wood residues » from within their own market. Why use recycled wood? Motivations: - Increase demand for « green products» by our clients (EPP, LEED, etc.) - Limited natural resources - Increase the life cycle of wood - Protect the environment by stopping disposal of wood - Prohibitive cost for waste disposal Tafisa specification for wood KRUGER • THE KRUGER ORGANIZATION • Kruger is a major pulp and paper company engaged in the manufacturing and sale of newsprint, specialty grades, lightweight coated paper, directory paper, tissue, recycled linerboard, corrugated containers, lumber and other wood products, including DRIcore, the most recently patented unique engineered sub-flooring system. Kruger Energy Inc.is a producer of green and renewable energy. Kruger Products, a member of the Kruger Company, is the leading tissue manufacturer in Canada. Scott Paper serves the Canadian consumer market with well-known brands including Cashmere, Purex, SpongeTowels, Scotties, White Swan, White Cloud, as well as away from home products for industrial and commercial use across Canada. • • The Kruger company has operations in Québec, Ontario, Alberta, British Columbia and Newfoundland and Labrador, the United States, United Kingdom and employs over 10,000 people. Kruger specifications for wood In compliance with Kruger authorization for energetic recovery for our cogeneration plant in Sherbrooke, the received materials must meet the following norms (mass analysis of residue will be done to evaluate residue compliance): 1.Total halogen content (fluorine, chlorine, bromine, iodine and astatine) must always be less than 0.15% of the wet weight 2.The supplied material will contain a minimum of 75% biomass (wood residue with no treatment and no paint) 3.The following materials may be included in the mix but are not considered as biomass Carton fiber panels, paper, paperboard, pressed wood panels (MDF, HDF, etc.), plywood Contaminants other than wood (total mass of contaminants must always be less than 5% in dry weight): -Asphalt shingle -Gypsum, metal, glass, ceramic -Stone, sand, ash and/or concrete -Acoustic products & insulation material -Plastics (styrofoam, urethane, vinyl, vapor barrier, ABS, etc.) -Fiberglass Kruger specifications for wood (2) • • • • • • • • • The following materials must never be delivered (0% non detectable visually) Dangerous goods Asbestos and/or Magnesium Paints, oils, solvents, glues & other similar materials Treated wood (0%) with creosote, copper arsenate (CCA), or pentachlorophenol (PCP) Any other materiel not listed above All combustibles will be delivered shredded with a maximum dimension of 15 cm (6 inches) and a target of 0 to 10 cm (0 to 4 inches) The maximum humidity will be 35%, if this limit is crossed, then Kruger could refuse the delivery or reduce the paid price. The sampling will be taken at the delivery as per received Kruger instructions. TAGER • The TAGER project is basically the creation of a purchasing group between Tafisa Canada and Kruger inc. TAGER is the abbreviation of Tafisa and Kruger • The need for such a group comes from a synergy between the companies regarding recycled wood. Tafisa needs good quality recycled wood and Kruger needs low quality recycled wood for fuel in their cogeneration plants. In the market, this new entity would be able to purchase and use all the grades of recycled wood. • This synergy will grow and some new projects will be created were we see fit Our need for wood • For Tafisa in 2009 the wood need for board material is going to be 150,000 GT and for boiler fuel 40,000 GT • For Kruger the need for cogeneration will be 200,000 GT • A grand total of 390,000 GT Conclusions - Wood products, such as particleboard and medium density fiberboard, offer opportunities as an eco-efficient material for the mitigation of climate change. Over ninety percent (90%) of the total panel composition is wood fibers derived from a renewable source and most importantly offering a recyclable store of carbon. By increasing the use of wood for energy production derived from sources traditionally flowing to the composite industry will create severe distortions in the carbon cycle. • All instruments (including government incentives) to enhance the use of wood, wood residues and wood wastes as a renewable raw material or a renewable energy source should: • Consider all wood residues and wastes that are suitable for the production of wood-based products in the first place for material recycling; • Consider all wood residues and wastes not suitable for recycling as biomass fuel. • It is estimated that we create 54 man hours per dry ton of wood in the panel and resulting woodworking industry as opposed to 2 man hours per dry ton when used as a biomass. • Only burn wood after it has been fully and soundly used Conclusions •Sourcing urban wood residues (waste) from Massachusetts and New England represents an economic fibre re-use strategy with distinct environmental benefits. •Superior to land-filling, burning as co-generation, etc. • Tafisa and Kruger are long-term players committed to the New England marketplace. • Sourcing urban wood residues from New England makes long term sense to both our companies, and, not a short-term/opportunistic transaction. • By working together, Massachusetts, New England and us can benefit by solving long-disposal and sustainable fibre supply issues. • This relationship would make a strong sustainable environmental statement based on a sound economic foundation.