Utility Analysis - University of Dayton

advertisement

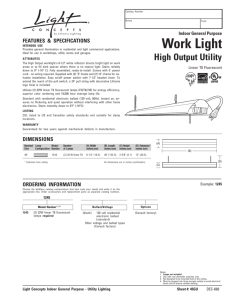

Energy Efficient Lighting Introduction In the U.S., about 19% of all electricity is used for lighting (ACEEE, 2000). Typical lighting power densities are about 1-2 W/ft2 in the commercial sector and 1-1.5 W/ft2 in the manufacturing sector (UD-IAC, 2008). Modern lighting systems are much more energy efficient that previous systems. Thus, upgrading older lighting presents an opportunity for energy savings. However, an effective lighting system must do more than deliver light efficiently. Effective lighting must provide the right quantity of light, with good color rendition and minimal glare. Quality lighting and day lighting has been shown to improve productivity and enhance worker satisfaction. In most cases, small improvements in worker productivity greatly outweigh lighting energy costs. Thus, when considering upgrades to reduce lighting energy use and costs, it is essential that the changes maintain or improve the quality of light. Inside-Out Approach to Energy Efficient Lighting The whole-system inside-out approach to identifying savings opportunities leads to the greatest savings at the least first cost. First, develop a baseline by documenting the current lighting system. Next, look for savings opportunities when current lighting is not providing useful light. Next, investigate the lighting distribution system, including light position and fixture efficiency. Finally, consider the actual energy conversion equipment, the lights, and look for more energy efficient options. To develop a lighting baseline: Record lighting level (fc), light quality (CRI), lighting type, input power and occupied hours for each area within a facility. Compare measured lighting levels with those recommended by the Illuminating Engineering Society. Evaluate daylighting options. Record fenestration area, orientation, and transmittance. Record lighting levels in daylit spaces with and without additional electric lighting. Note glare issues. Evaluate quality of light in daylit spaces compared to other spaces. End use lighting savings opportunities include: Turn off blocked lights and lights in unoccupied areas. Use motion sensors to turn off lights in seldom used areas such as warehouses. Turn off unnecessary lights near windows or skylights. Use photo sensors to turn on/off outdoor lights. Determine required light level and disconnect lights in overlit areas. Replace colored glass and fiberglass with corrugated polycarbonate, and turn off unnecessary lights. Energy Efficient Lighting 1 Add windows or skylights, and turn off unnecessary lights. Next, consider the lighting distribution system. Savings opportunities include: Clean dirty lenses and replace yellowed lenses. Add reflectors to fluorescent strip lights. Add task lighting over critical areas and decrease general lighting. Lower lights beneath scaffolding. Paint ceilings and walls lighter color. Finally, consider lighting replacement options. Savings opportunities include Replace incandescent and halogen lights with compact fluorescent lights. Replace T12 fluorescent lights with T8 or T5 lights and electronic ballasts. Replace HID lights with HBF lights. Productivity and Lighting Several studies have documented productivity improvements due to lighting upgrades and the increased use of sunlight for interior lighting. A few examples are listed here. Lighting Upgrades In the post office in Reno, Nevada, a lighting retrofit with a six-year payback increased the number of letters sorted per hour by 6% and decreased the rate of sorting errors to 0.1% making the Reno Post Office the most efficient in the Western US. Energy savings were about $22,400 per year, but the increase productivity was worth about $400,000 per year (Romm and Browning, 1999). Boeing recently went through a lighting upgrade with a two-year payback. In addition to energy savings, “the things that people tell us are almost mind boggling”, said one manager. Machinists report being able to read calipers and tools more easily. The improved contrast improves workers ability to detect imperfections in the shop by 20%. This is important because “most of the errors… weren’t picked up until installation in the airplane, where it is much more expensive to fix” (Romm and Browning, 1999). Hyde Tools lighting upgrade reduced electricity costs by $48,000 per year. However, “the quality of work improved significantly because we could see things we couldn’t see before”. The manager estimates that the improved lighting results in about $250,000 per year in additional revenue (Romm and Browning, 1999). Pennsylvania Power and Light saved $2,000 per year from their lighting upgrade, but the time required to produce drawings decreased, saving them another $42,000 per year. In addition, sick leave decreased from 72 to 54 hours per year. Energy Efficient Lighting 2 It was apparent that “low quality seeing conditions were causing morale problems among employees” (Romm and Browning, 1999). West Bend Mutual Insurance Company’s move to a new building with advanced HVAC and better lights reduced electricity costs from $2.16 /ft2 to 1.32 /ft2, and improved productivity by 16.8% (Romm and Browning, 1999). Day Lighting The Herman Miller company built a new manufacturing plant with a large portion of its lighting provided by skylights. Production output has consistently been over 20% higher than in the previous electrically-lighted plant. Employees report that working conditions are excellent (McDonough, 2008). Lockheed Missiles and Space Company commissioned a new office building in California in which the cost of extensive day lighting added an extra 4% to the buildings cost. However, electricity costs will be reduced by about $500,000 per year for a four- year payback. In addition, absenteeism dropped by 15%, which paid for 100% of the first cost in the first year (Romm and Browning, 1999). Skylights were installed on one half of the roof of a Wal-mart in Lawrence, Kansas. Sales data indicated that the departments under the skylights sold more than the departments under the electric lighting, and more than similar departments in other stores. To test whether this was due to the skylights, the departments were switched from one side of the store to the other. As before, sales from departments under the sky lights increased (Romm and Browning, 1999). A 1999 study conducted for Pacific Gas and Electric evaluated elementary student test scores and found that, in classrooms with daylight, test scores improved by over 20+%. Retail sales in a chain of 100+ similar stores were also evaluated. Sales were found to be as much as 40% higher in stores with skylighting (Heschong Mahone Group, 1999). Lighting Fundamentals Effective, energy-efficient lighting systems provide the right quantity of light, with good color rendition and minimal glare, while minimizing energy-use. Each of these concepts is described briefly in the sections that follow. Light Quantity The quantity of visible light radiated by a light source is measured in lumens. The theoretical upper limit for the conversion of energy to light is 683 lm/W. Natural daylight has luminous efficacy of about 110 lm/W. Electric lighting ranges from about 10 to 100 lm/W. Illuminance is the quantity of light divided by the area on which it is incident. Illuminance can be measured by light meters. The common measure of Energy Efficient Lighting 3 illuminance in U.S. units is footcandles. One footcandle is one lumen per square foot. 1 fc = 1 lm/ft2 The Illuminating Engineering Society of North America (IESNA) publishes recommended lighting levels for various tasks and spaces. IESNA recommended lighting levels for some common spaces are shown in the table below (IESNA Handbook, 9th Edition). In general, recommended lighting levels increase as the size and contrast of the visual task decrease. Thus, the recommended lighting level will be near the lower level of the range shown in the table below when the size and/or contrast of the visual task is large, and will be near the upper level of the range when the size and/or contrast of the visual task is small. For example, 15 fc may be sufficient for warehouses with large bulk items, but 25 fc may be needed for warehouses with hand-stocked items. Similarly, 30 fc may be sufficient for general manufacturing, but 50 fc may be required for manufacturing tasks requiring visual precision. Space/Function Offices and classrooms Corridors Restrooms Dining rooms Merchandise Display Warehouse Manufacturing Inspection Recommended Lighting Level (fc) 30-50 5-10 5 10 50 5-30 30-50 50-100 Light Quality Our eyes evolved to see in natural sunlight; thus, we distinguish colors best in sunlight. Light from electric lamps is generated at lower temperatures than sunlight and reduces our ability to distinguish between colors. Color Rendering Index (CRI) describes the effect of a light source on the color appearance of an object. CRI varies between 0 and 100. Approximate CRIs of various types of lighting are shown in the table below. Light Type Sunlight Incandescent T8 Fluorescent Metal halide T12 Fluorescent (cool white) High-pressure sodium CRI 100 99 75-85 65 60 22 Some tasks, such as inspection and painting, clearly require high-quality light. In addition, most people prefer to work and live in light that is as close to sunlight as Energy Efficient Lighting 4 possible; thus the CRI of a light source should always be a consideration when selecting lights. For example, most people report seeing better under fluorescent lights with a CRI of 85 than under high-pressure sodium lights with a CRI of 22, even when the illuminance under the high-pressure sodium lights is higher. Glare Glare is uncomfortably high illuminance. Glare can be problematic with large windows with direct sunlight and with direct high-intensity artificial lighting. For this reason, windows are often equipped with some type of shading and luminaries are often designed to diffuse light. Electric Lighting Common types of electrical lighting fall into three categories: incandescent, fluorescent and high-intensity discharge. Important characteristics of each category are described below. Incandescent Lights Thomas Edison invented the incandescent light bulb and it remains essentially unchanged today. Incandescent lights produce light by simple radiation from a heated tungsten filament. The lighting efficiency is generally low since most of the energy is released as infrared radiation rather than visible light. In recent years, halogen has been added to the filament increasing the efficiency and light output by about 30% in ‘halogen lights’. Incandescent lights are inexpensive, require almost no warm-up time, and the lighting output does not degrade significantly over time. However, because of their inefficiency, they are being replaced by compact fluorescent lights that use about 30% as much energy and last about seven times longer. Fluorescent Lights Fluorescent lights work by energizing Ar, Ar-Ne or Kr gasses inside a tube. The gasses produce UV radiation that is converted to visible light when it interacts with phosphor coatings on the inside of the tube. Fluorescent lights have a higher lighting efficiency than incandescent lights. They start quickly and lighting output degrades only moderately over time. Fluorescent lamps are labeled using “F” and “T” notion. The “F” notation refers to the nominal wattage of the lamp. The “T” notation denotes the diameter in units of 1/8 inch. Thus, Thus ‘F32T8’ refers to a lamp with nominal power draw of 32 W and 1 inch diameter. Over time, the progression has been toward thinner lamps, from T12 to T8 to T5, with corresponding improvements in energy efficiency and color rendition. Tubular fluorescent lamps with low mercury content are generally marked with green end caps. All fluorescent lights require ballasts. The ballast regulates voltage and uses some energy itself. Old-style T12 lamps used magnetic and electro-magnetic ballasts. T8 and T5 lamps use electronic ballasts. New electronic ballasts are more energy- Energy Efficient Lighting 5 efficient, eliminate the flicker associated with old-style magnetic ballasts, are quieter and contain less heavy metals than old-style ballasts. The actual power draw of the lamp, and the corresponding lamp output are determined by the power supplied to the lamp by the ballasts. The relative power delivered by the ballast to the lamps is called “ballast factor”. For example, lamps powered by a ballast with a ballast factor of 0.87, will draw about 87% of their rated wattage and deliver about 87% of their rated lighting output. The fixture that houses the lamps and ballast and directs the light onto the work plane is called a luminaire. The most common types of fluorescent luminaries are recessed-troffer and suspended luminaires. Many offices employ recessed-troffer luminaires. The troffers are typically equipped with acrylic lenses or parabolic grids to diffuse the light. Although acrylic lenses transmit more light than parabolic grids, parabolic grids produce less glare and are therefore widely used in rooms with video displays. Recessed parabolic and lensed troffers. In industrial applications, fluorescent luminaires are typically suspended from the ceiling. Simple “strip” lights without reflectors attached to the sides lose a significant amount of the light sideways and upwards. Adding reflectors to the sides of the luminaire pushes more light downward onto the work plane, and reduces the number of lights required to generate a given lighting level on the work plane. The most efficient fluorescent luminaires employ polished metal mirrors above each lamp to direct the maximum possible light onto the work plane. High-bay fluorescent (HBF) luminaires employ these polished reflectors, and are displacing HID lights in industrial applications due to their improved energy efficiency, color rendition and other attributes. A) fluorescent strip light, B) fluorescent strip light with side reflectors, C) high-bay fluorescent light with individual polished mirror reflectors. Energy Efficient Lighting 6 High-Intensity Discharge Lights High-intensity discharge (HID) lights are primarily used in applications with high ceilings or for outdoor lighting. The most common types of HID lights are metal halide (MH) and high-pressure sodium (HPS). MH lights produce a white light with a CRI of about 65, and have a lighting efficiency of about 70 lm/W. HPS lights have a lighting efficiency of about 95 lm/W, but produce a yellow light with poor color rendering (CRI = 20); thus, these lights are best suited for outdoor and warehouse applications. All HID lamps require a ballast. The ballast for a typical 400-W HID lamp uses 50 to 65 W. HID lamps take about 3 minutes to start-up when cold and about 25 minutes when warm. Thus, most HID lighting systems include a few fluorescent safety lights that start up immediately in the advent of a power interruption. Two-stage and dimmable HID ballasts with occupancy sensors are available, Twostage HID ballasts typically have a low-lighting stage that produces 35% of the light while using 50% of the rated energy. Luminaries for HID lights typically use acrylic or spun-aluminum reflectors. Acrylic reflectors spread about 10% of the light horizontally and toward the ceiling. Because of this, they are often used in retail applications where bright ceilings are more visually attractive. Spun aluminum reflectors are the most common type in industrial applications and direct all light toward the floor. HID luminaries are classified as high-bay for placements higher than about 25 feet, and low-bay for placements less than about 25 feet. Low-bay luminaries have acrylic lenses that spread the light outward over a wider surface area. A) acrylic high-bay luminaire, B) aluminum high-bay luminaire, C) aluminum low-bay luminaire with acrylic lens. Comparative Characteristics The efficiency of converting electricity to light can be measured as the ratio of light output (lm) and electrical power (W). All common types of electric lights except incandescent lights require a ballast to regulate the voltage to the lamp. Thus, the lighting efficiency should include the electricity consumed by both the lamp and ballast. The lighting output of most types of lights degrades over the lifetime of the light, thus the mean lighting output should be used when calculating energy efficiency. The approximate lighting efficiencies of common Energy Efficient Lighting 7 types of lighting systems (including ballasts), and other characteristics are shown in the table below. Light Type Efficiency (Lm/W)* 18 70 58 100 70 96 CRI Lifetime (hours) 750 10,000 20,000 20,000 20,000 20,000 Lumen Maint. Good OK Good Good Fair Good Restrike Time Instant Immediate Immediate Immediate 30 min 30 min Incandescent 99 Compact fluorescent 60 T12 Fluorescent 60 T8 Fluorescent 75 Metal halide 65 High-pressure 22 sodium *Typical lm/W calculated using mean lighting output (lm) and energy use (W) including ballast. Performance Metrics Typical performance and cost data for common lamps and ballasts are shown below. Fluorescent and HID lamps are generally specified by a nominal power draw and nominal light output. However, the power to a lamp is regulated by a ballast. Thus, the actual power draw of the lamps plus the ballast, and light output of the lamps is determined by the ballast. Example 4-ft T8 fluorescent lamps have a nominal power draw of 32 W each and nominal light output of 2,710 lm each. Using data from the tables shown below, calculate the actual power draw and lighting output of two 32-W lamps when powered by a single low-output electronic ballast, and when powered by a high-output electronic ballast. The power consumption of a single low-output electronic ballast is 51 W and the power consumption of a single high-output electronic ballast is 77 W. Thus, Power input of 2 lamps and the ballast for low output ballast = 51 W Power input of 2 lamps and the ballast for high output ballast = 77 W The actual light output of a lamp is the product of the nominal rated light output and the ballast factor associated with the ballast. Thus, the actual light output of two 32-W lamps with nominal rated output of 2,710 lm each, when powered by a low-output electronic ballast with ballast factor 0.75 is: Light output (low output ballast) = 2 lamps x 2,710 lm/lamp x 0.75 = 4,065 lm Energy Efficient Lighting 8 If the same lamps were powered by a high-output electronic ballast with ballast factor 1.20 the actual light output would be: Light output (high output ballast) = 2 lamps x 2,710 lm/lamp x 1.20 = 6,504 lm Similarly, a metal halide lamp may be labeled with a nominal power draw of 400 W and nominal light output of 23,500 lm. However, as shown in the tables below, the lamp and the ballast together draws 460 W. HID ballasts generally have a ballast factor of 1.0. Thus, the actual light output of HID lamp is equivalent to the nominal light output of the lamps. Fluorescent Lamps Type 4-ft T12 48-in T12 34-W 48-in T12 40-W 4-ft T8 48-in T8 32-W 48-in T8 32-W, long life, low merc 48-in T8 32-W, cover guard 8-ft T12 96-in T12 60-W 96-in T12 95-W 96-in T12 110-W 8-ft T8 96-in T8 59-W 96-in T8 59-W, cover guard 96-in T8 86-W Energy Efficient Lighting 9 Nominal Power (W) Rated Life (hr) Mean Output (lm) CRI Cost ($) 34 40 20,000 20,000 2,280 2,910 62 73 1.40 4.00 32 32 32 20,000 24,000 20,000 2,710 2,710 2,625 78 75 78 1.90 2.60 11.00 60 95 110 12,000 12,000 12,000 5,060 6,960 7,740 62 60 60 3.90 6.00 13.00 59 59 86 15,000 15,000 18,000 5,310 5,150 7,200 75 75 75 7.80 24.10 17.70 Fluorescent Ballasts Type Lamps Lamp Power (W) Ballast Power (W) Ballast Factor 2 34 68 .87 2 2 2 32 32 32 51 58 77 .75 .87 1.20 2 2 2 60 95 110 112 203 237 .88 .91 .95 2 2 59 86 110 160 .85 .88 4-ft T12 Fluor F34T12 Electromagnetic 4-ft T8 Fluor F32T8 Electronic (Low Output) Fluor F32T8 Electronic (Normal Output) Fluor F32T8 Electronic (High Output) 8-ft T12 Fluor F96T12 Electromagnetic Fluor F96T12 Electromagnetic Fluor F96T12 Electromagnetic 8-ft T8 Fluor F96T8 Electronic Fluor F96T8 Electronic Cost ($) $36 $15 $36 $25 $29 Metal Halide Lights 175 W 250 W 360 W 400 W 1,000 W 1 1 1 1 1 kW/fix 0.210 0.295 0.420 0.460 1.080 Lum/fix 8,800 13,500 23,500 23,500 66,000 Hours/lamp 10,000 10,000 20,000 20,000 12,000 Cost/lamp $27 $26 $50 $23 $74 Cost/fix*: Low Bay $225 $215 $250 $250 $205 Cost/fix*: High Bay --65 --65 $110 65 $110 65 $235 65 Lamps/fix CRI High-Pressure Sodium Lights 70 W 100 W 150 W 250 W 400 W 1,000 W 1 1 1 1 1 1 kW/fix 0.088 0.128 0.185 0.300 0.465 1.110 Lum/fix 5,450 8,550 14,400 27,000 45,000 126,000 Hours/lamp 24,000 24,000 24,000 24,000 24,000 24,000 Cost/lamp $27 $23 $21 $21 $19 $83 Cost/fix* $163 22 $165 22 $160 22 $196 22 $216 22 $360 22 Lamps/fix CRI Energy Efficient Lighting 10 High-Bay Fluorescent Lights T8 T8 T8 T5 T5 T5 4 6 8 4 6 8 kW/fix 0.156 0.234 0.312 0.236 0.354 0.472 Lum/fix ** 13,680 20,520 27,360 24,000 36,000 48,000 Hours/lamp*** 24,000 24,000 24,000 24,000 24,000 24,000 Cost/lamp $2.50 $2.50 $2.50 $15 $15 $15 Cost/fix* $120 $150 $200 $170 $230 $300 Cost/occ sen $70 $70 $70 $70 $70 $70 CRI 85 85 85 85 85 * Fixture cost includes lamp, ballast and luminaire ** Assumes three 2-lamp, 1.2 BF, 78-W ballasts ***Assumes long-life lamps rated at 24,000 hours with cycle of 3 hours/start. 85 Lamps/fix Lighting Design The Illuminating Engineering Society (IES) lumen method calculates the illuminance on a workplane, Ew (fc), as: Ew = Cu x F / Aw where Cu is the coefficient of utilization, F is the total lumens produced by the lamps, and Aw is the area of the work plane. Cu is a calculated from a manufacturer-supplied table based on the type of luminaire, room geometries and surface reflectivities. Typical Cus range from about 0.2 to 0.6 (Kreider and Rabl 1994) Heating and Cooling of Buildings. This equation can also be written as Ew = Cu x (LPF x N) / Aw Where LPF is the lumens per fixture and N is the number of fixtures. In fluorescent lights, lumens per fixture LPF is the product of the number of lamps, NL, lumens per lamp, LPL, and the ballast factor, BF. LPF = NL x LPL x BF To determine how many fixtures are needed simply solve this equation for N. N = (Ew x Aw) / (Cu x LPF) Values of the coefficient of utilization, CU, for typical 4-lamp fluorescent troffer fixtures, 400-W high-bay metal halide fixtures and 6-lamp high bay fluorescent fixtures are shown in the tables below. Energy Efficient Lighting 11 CU values for recessed 2’ x 4’ fixture with acrylic lens and 4 lamps (www.columbialighting.com) CU values for 8-ft 4-lamp or 4-ft 2-lamp fluorescent fixture (www.goodmart.com) CU values for high-bay 400-W MH or HPS fixture (www.cooperlighting.com) Energy Efficient Lighting 12 CU values for high-bay six-lamp ORION 416 HPM fluorescent fixture (www.orionlighting.com) In each table CU depends on the room cavity ratio, RCR, where RCR = 5 x h x (w + l) / (w x l) CU also depends on the reflectivity of the ceiling, rc, and the reflectivity of the walls, rw. Most paint color chips report Light Reflecting Value (LRV), which is the reflectivity. Light surfaces have a high reflectivity. Source: http://www.squidoo.com/LRV Electrical Lighting Design Example Determine the number of 400-W metal halide fixtures and 230-W high-bay fluorescent fixtures required to light a space with the following characteristics: Ew = 40 fc W = width = 50 ft L = length = 100 ft H = height = 25 ft Rc = reflectivity of ceiling = 50% Rw = reflectivity of walls = 50% Solution: Energy Efficient Lighting 13 RCR = 5 x h x (w + l) / (w x l) = 5 x 25 x (50 + 100) / (50 x 100) = 3.75 ~ 4.0 CU (400-W metal halide) = 0.57 CU (230-W high-bay fluorescent) = 0.69 LPF (400-W metal halide) = 23,500 lm LPF (230-W high-bay fluor, w/ 3 2-lamp, 1.2 BF, 78-W ballasts at 8,000 hrs) = 3 x 6,840 lm = 20,520 lm N = (Ew x Aw) / (Cu x LPF) N (400-W metal halide) = (40 x [50 x 100]) / (.57 x 23,500) = 14.9 ~ 15 lights N (230-W high-bay fluorescent) = (40 x [50 x 100]) / (.69 x 20,520) = 14.1 ~ 14 lights Lamp Replacement Costs Overtime, lamps fail and need to be replaced. Thus, economic analysis of lighting upgrades should consider lamp replacement costs. The number of lamps that must be replaced each year, Nr, can be calculated as: Nr = Nt x AOH / LL Where: Nt = total number of lamps in operation AOH = annual operating hours LL = lamp lifetime Lamp Replacement Cost Example Consider lamp replacement savings from replacing 320 400-W MH fixtures with 320 6-lamp HBF fixtures if the lights operate 8,000 hours per year. The number of lamp replacements would be about: MH: (320 fix x 1 lamps/fix) x 8,000 hours/year / 20,000 hours = 128 lamps/year T8: (320 fix x 6 lamps/fix) x 8,000 hours/year / 30,000 hours = 512 lamps/year The cost of a 400-W MH lamp is about $23, and T8 lamps cost about $3 each. The hourly wage for a skilled-trade electrician, including all benefits, is about $65 per hour. Assuming it would take one worker about 30 minutes to replace either a single MH lamp or 6 T8 lamps, the annual maintenance costs are about: MH: 128 lamps/year x ($23 /lamp + (30/60 hours/lamp x $65 /hour)) = $7,104 /year Energy Efficient Lighting 14 T8: 512 lamps/year x ($3 /lamp + (30/60 hours / 6 lamps x $65 /hour)) = $4,309 /year Thus, the annual maintenance savings would be about: $7,104 /year - $4,309 /year = $2,795 /year Economics of Lighting Upgrades The methods described above can be used to determine the economics of lighting upgrades. The method typically involves the following steps. Calculate how many of the proposed lights are needed to deliver the required number of footcandles in the space. Calculate the annual energy cost savings of replacing the current lights with the proposed lights. Calculate the annual relamping cost savings, including both labor and material costs. Calculate total annual cost savings including both annual energy and annual relamping savings. Calculate the one-time implementation cost of replacing the current lights with the proposed lights. Calculate the simple payback of the investment. The performance and coefficient of utilization data from the preceding sections can be used in these calculations. Lighting Upgrade Economics Example A facility has 25 fixtures with 400-W high pressure sodium (HPS) lamps. A lighting upgrade to 6-lamp T8 high-bay fluorescent (HBF) fixtures is proposed. The lights operate 6,000 hours per year and the average cost of electricity is $0.10 /kWh. The hourly wage for an electrician is $50 per hour. It takes an electrician 15 minutes to replace either a single HPS lamp or 6 T8 lamps. It takes an electrician 30 minutes to replace a HPS fixture with a new HBF fixture. Determine annual cost savings including energy and lamp replacement costs, the implementation cost, and simple payback of the project. The space has the following characteristics: Ew, required = 50 fc W = width = 150 ft L = length = 100 ft H = height = 25 ft Rc = reflectivity of ceiling = 70% Rw = reflectivity of walls = 70% Energy Efficient Lighting 15 Solution: The number of HBF fixtures required would be: RCR = 5 x h x (w + l) / (w x l) = 5 x 25 x (150 + 100) / (150 x 100) = 2.0 CU (HBF) = 0.93 LPF (HBF) = 20,520 lm N (HBF) = (Ew x Aw) / (Cu x LPF) N (HBF) = (50 x [150 x 100]) / (.93 x 20,520) = 34 fixtures The energy cost savings would be: Esav = [(25 fix x .465 kW/fix) – (34 fix x .234 kW/fix)] x 6,000 hr/yr Esav = 22,014 kWh/yr ECsav = 22,014 kWh/yr x $0.10 /kWh = $2,201 /yr The number of annual lamp replacements would be: HPS: (25 fix x 1 lamps/fix) x 6,000 hours/year / 24,000 hours = 6 lamps/year HBF: (34 fix x 6 lamps/fix) x 6,000 hours/year / 24,000 hours = 51 lamps/year The annual lamp replacement costs would be: HPS: 6 lamps/year x ($19 /lamp + (.25 hr/lamp x $50 /hr)) = $189 /yr HBF: 51 lamps/year x ($2.5 /lamp + (.25 hr/ 6 lamps x $50 /hr)) = $234 /yr The annual lamp replacement savings would be: $189 /year - $234 /year = -$45 /year The total annual savings would be: $2,201 /year - $45 /year = $2,157 /year The implementation cost and simple payback would be: IC = 34 fix x [$200 /fix + (.50 hr/fix x $50 /hr)] = $7,650 SP = $7,650 / $2,157 /yr x 12 mo/yr = 43 months Natural Lighting Design Natural lighting uses light through skylights in the roof of a building or windows in the walls of a building. Energy Efficient Lighting 16 Illuminance from Skylights The Illuminating Engineering Society (IES) lumen method to calculate the illuminance on a work plane, Ew (fc), from the illuminance on a horizontal skylight Esl (fc) is: Ew = Esl x Cu x transmissivity of the skylight x transmissivity of the well x Asl / Aw Where Cu is the coefficient of utilization, Asl is the area of the skylight and Aw is the area of the work plane. Cu is a function of ceiling reflectivity, pc , wall reflectivity, pw, and the room cavity ratio, RCR. Values of Cu for skylights are tabulated in Table 13.5 of Kreider and Rabl, 1994, Heating and Cooling of Buildings. An adequate approximation is given by: Cu = 1.016898 + 0.074074 pc + -0.14778 RCR + 0.111111 pw + 0.037037 pc2 + 0.008133 RCR2 + 0.125 pw2 The room cavity ratio, RCR, is: RCR = 5 x h x (w + l) / (w x l) where h is the height of the skylight over the work plane, w is the width of the room and l is the length of the room. Design values of the illuminance on a skylight, Esl, can be found in Figures 13.4 – 13.6 of Kreider and Rabl, 1994, Heating and Cooling of Buildings. Alternately, Esl can be calculated from the total radiation on a horizontal surface Ih (Btu/hr-ft2) by assuming that the illuminance of sunlight is 110 lm/W. Esl (fc) = Ih Btu/hr-ft2 / 3.413 Btu/W-hr x 110 lm/W x 1 fc/(lm/ft2) According to a local roofing company contacted in 2002, the material and installation for a 4 ft by 4 ft skylight with a 10-foot shaft would cost about $2,000. Illuminance from Skylights Example A 50 ft by 50 ft room with a 25 foot ceiling has 50 ft2 of skylights. The total solar radiation on the skylights is 300 Btu/hr-ft2. Calculate the illuminance on the floor. The reflectivity of the walls is 0.70 and the reflectivity of the ceiling is 0.70. The average transmissivity of each skylight is 0.80 and the average transmissivity of each skylight well is 0.90. Assuming that the illuminance of sunlight is 110 lm/W, the illuminance on a skylight, Esl, is: Esl = Ih Btu/hr-ft2 / 3.413 Btu/W-hr x 110 lm/W x 1 fc/(lm/ft2) = 9,669 fc Energy Efficient Lighting 17 The room cavity ratio, RCR, is: RCR = 5 x h x (w + l) / (w x l) = 5 The coefficient of utilization, Cu, is: Cu = 1.016898 + 0.074074 pc + -0.14778 rcr + 0.111111 pw + 0.037037 pc2 + 0.008133 rcr2 + 0.125 pw2 = 0.690 The illuminance on a work plane, Ew (fc), is: Ew = Esl x Cu x transmissivity of skylight x transmissivity of well x Asl / Aw = 96 fc Illuminance from Vertical Windows The IES recommends an illuminance of about 20 fcs for warehouse spaces and 50 fc for precision work. The general equation to calculate the illuminance on a work plane, Ew (fc), from the illuminance on a vertical window Ev (fc) is: Ew = Ev x Cu x transmissivity of the window Where Cu is the coefficient of utilization. Cu is a function of the window length and height, room depth and the distance between the window and the work plane (expressed as a fraction of the room depth). Values of Cu for windows are tabulated in Table 13.8 or Kreider and Rabl, 1994, Heating and Cooling of Buildings. Design value of the illuminance on a vertical window, Ev, can be found in Figures 13.4 – 13.6 of Kreider and Rabl, 1994, Heating and Cooling of Buildings. Alternately, Ev can be calculated from the total radiation on a vertical surface Iv (Btu/hr-ft2) by assuming that the illuminance of sunlight is 110 lm/W. Ev (fc) = Iv Btu/hr-ft2 / 3.413 Btu/W-hr x 110 lm/W x 1 fc/(lm/ft2) If the window is shaded from direct solar radiation, then the Iv should be the diffuse component of solar radiation. LightSim Daylighting Analysis Software LightSim daylighting analysis software simulates hour-by-hour illuminance on a work plane using TMY2 meteorological data. It is specifically designed to assess the feasibility of daylighting in buildings. LightSim can quickly determine the fraction of time that various daylighting designs can meet or exceed a target illumination on a work plane. LightSim is available at no cost from the University of Dayton IAC. Energy Efficient Lighting 18 Photo Controls Photo controls turn lights on and off depending on lighting levels or occupancy. In indoor lighting applications, photo controls are most often used with fluorescent or incandescent lights since these lights turn on and off quickly. Photo controls are seldom used with HID lighting in indoor applications, because of the 15minute restrike time required for HID lighting to regain full output. Photo Sensors Photo sensors measure light levels and control lights based on the difference between the measured light level and a set point. In outdoor applications, photo sensors turn lights off during the day and on during night, with an average on-time of 12 hours per day. Most outdoor HID lights come with a ½-inch knockout or an 11/16-inch hole for easy screw-in mounting. Most photo sensors have built-in delays to prevent false cycling from headlights, etc. Photo sensors typically cost less than $15 each and can be installed in less than ½ hour. Thus, it is virtually always cost-effective to install photo sensors on outdoor lights to prevent lights from running during daylight hours. In indoor applications, photo sensors turn off unnecessary lights in day lit spaces. Occupancy Sensors Occupancy sensors turn lights on when a space is occupied and turn lights off about 4 minutes after the space is unoccupied. Most occupancy sensors use infrared sensors to detect body heat in motion. In commercial buildings, occupancy sensors are especially effective in lightly used areas, such as lavatories or conference rooms, or in rooms where lights may be left on inadvertently. In manufacturing facilities, occupancy sensors are especially effective in ware house areas with limited traffic between rows of stacks. Residential occupancy sensors cost about $15 each and commercial/industrial quality occupancy sensors cost between $80 and $200 each. Ballast and Lamp Disposal Ballasts manufactured before 1979 contained wet-capacitors with the hazardous waste PCB. After 1979, ballasts used dry capacitors and contain no appreciable hazardous wastes. Because very few pre-1979 ballasts remain, most states allow post-1979 ballasts to be disposed of in normal waste streams. Fluorescent and HID lamps contain small amounts of mercury in the phosphor powder. Mercury is a potent neurotoxin and is harmful to both animals and humans. When unbroken lamps are disposed of in landfills, virtually no mercury leaches into the environment. However, if lamps are incinerated, the mercury is transported through the atmosphere to water, animals and humans. Spent lamps can also be recycled; however, some studies indicate that more mercury is released into the environment during recycling than by placing the lamps in landfills. Energy Efficient Lighting 19 Currently, lamp disposal is regulated on a state-by-state basis, or indirectly by the 1990 RCRA, which recognizes mercury as a hazardous waste. In many states, all traditional spent lamps from businesses are considered hazardous waste irrespective of the number of lamps being disposed. In this case, spent lamps should be sent to a registered recycler or hazardous waste contractor. Under RCRA, small quantity generators that dispose less than 350 4-foot lamps per month can legally dispose of spent lamps into the municipal solid waste stream. In any case, if the municipal waste is incinerated, it is recommended that the lamps be sent to an EPA-registered recycler or hazardous waste disposal company. Be sure to research the credibility of the recycler or waste management company. If the waste is not disposed of properly, the original generator may be legally liable. Recyclers and hazardous waste handlers typically charge about 40 cents per lamp for disposal or recycling. For new lamp purchases, specify low-mercury lamps, which are commonly marked with green end-caps. Low-mercury lamps have about 5 milligrams of mercury compared to about 48 milligrams for 1985 vintage lamps. The additional cost for low-mercury lamps is usually negligible, and in most states, spent low-mercury lamps can be deposited directly in landfills instead of being sent to a lamp recycler. This saves disposal costs and reduces potential environmental legal liability issues. Compact fluorescent lamps contain about 4 mg of mercury. However, the 75% reduction in energy use compared to incandescent lamps displaces mercury emissions from coal fired power plants. The U.S. EPA estimates that the use of CFLs in place of incandescent lamps results in over three times less mercury emissions. Source: U.S. E.P.A., Information on CFLs and Mercury, 10/2010 Energy Efficient Lighting 20 Heating and Cooling Interactions Reducing the lighting energy added to a conditioned space decreases the space cooling load and increases the space heating load. From simple energy balances, the air conditioning electricity savings can be estimated as: [(Plights,pre - Plights,post) x hours/year ] / cooling The additional heating energy can be estimated as: [(Plights,pre - Plights,post) x hours/year] / heating Where Plights is the power draw of the lights and is the efficiency of the space conditioning equipment. Heating and Cooling Energy Example If the lighting load were decreased from 50 kW to 40 kW, for 2,500 hours per year during the cooling season, and the average efficiency (coefficient of performance) of an air conditioner is 3.0, calculate the air conditioning savings: The air conditioning savings would be: [(50 kW - 40 kW) x 2,500 hr/yr ] / 3.0 = 8,333 kWh/yr If the lighting load were decreased by the same amount for 2,500 hours during the heating season, and the average efficiency of a furnace was 75%, calculate the additional heating energy needed. The additional heating energy would be about: [(50 kW - 40 kW) x 2,500 hr/yr ] / 0.80 x 3,413 Btu/kWh = 117 x 106 Btu/yr Note that when the heating and cooling periods are about the same length, as in this example, the increased air conditioning and decreased heating costs may be nearly equal. For this reason, they are sometimes ignored. In buildings with complex HVAC systems, heating and cooling interaction effects can be more accurately modeled by building energy simulation software. Emerging Lighting Technologies Light emitting diodes (LEDs) are semiconductor materials that emit light when electricity is passed through them. Currently, LEDs are used in thin-screen computer monitors, thin-screen televisions, watches, exit signs, flashlights, traffic lights and many other applications. Their appeal lies in their energy efficiency and longevity. Current white light LEDs have efficiencies somewhere between incandescent lights, at about 5%, and fluorescent lights, at about 25%. Current Energy Efficient Lighting 21 LEDs last about 5 times as long as incandescent lights. For example, California has replaced thousands of 150-W incandescent light bulbs that last about 1 year in traffic lights with red, yellow and green LEDs that consume about 15 W and last about 5 years. A principle challenge for white light LEDs is converting the colored light produced by an LED into white light, which a combination of many colors of light. One current design uses a LED that produces UV light to stimulate phosphors which emit red, green and blue light in the proper proportion to make white light. Another approach is to develop organic LEDs, which resemble a patch of softly glowing plastic. Organic LEDs could someday be mass-produced using ink jet technology on a substrate. Theoretically, LEDs could be 100% efficient. (Technology Review, 2003). References American Council for an Energy-Efficient Economy, 2000, “Guide to EnergyEfficient Commercial Equipment”, Washington, D.C. Energy Information Administration, 1996, “Residential Lighting Use and Potential Savings” DOE/EIA-0555(96)/2, U.S. Department of Energy, Washington, DC, http://www.eia.doe.gov/emeu/lighting/. Energy Information Administration, 2002, “U.S. Lighting Market Characterization, Volume 1: National Lighting Inventory and Energy Consumption Estimate”, U.S. Department of Energy, Washington, D.C. Granger, 2001, “Grainger Industrial Supply Catalog 2000-2001”, No. 391. Heschong Mahone Group, 1999, “Daylighting in Schools” and “Skylighting and Retail Sales”, Pacific Gas and Electric, http://www.h-mg.com/Daylighting/daylighting_and_productivity.htm Kreider, J.F. and Rabl, A., “Heating and Cooling of Buildings”, 1994, McGraw-Hill Inc. McDonough, 2008, http://www.mcdonough.com/miller.html. Orion, Plymouth WI, www.orionlighting.com Romm and Browning, 1999, “Greening the Building and the Bottom Line”, Global Energy Conference, Vancouver, May. Suozzo, M., Benya, J., Hydeman, M., Dupont, P., Nadel, S. and Elliot, N., “Guide to Energy Efficient Commercial Equipment”, 2000, American Council for an Energy Efficient Economy. Energy Efficient Lighting 22 Technology Review, 2003, “LED vs. the Lightbulb”, May, pgs. 30-36. University of Dayton Industrial Assessment Center, 2008, Dayton, OH. Energy Efficient Lighting 23