Experimental Methods for Engineers

advertisement

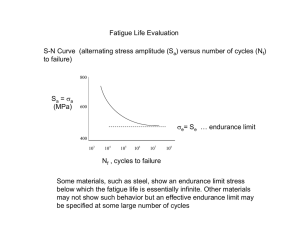

ME 388 – Applied Instrumentation Laboratory Fatigue Lab Objectives • Learn fatigue testing procedures – Wohler machine (Rotating cantilever beam machine) – R.R. Moore (Rotating beam machine) • Evaluate fatigue behavior of AA 6061-T6 – Generate S-N diagram – Determine endurance limit • Observe surface characteristics of fatigue failure References • Shigley and Mischke, Mechanical Engineering Design, 6th edition • Metals Handbook, Vol.2, 10th edition, ASM International • Holmon, Experimental Methods for Engineers, 6th edition • www.matls.com AA 6061 – T6 • Most common structural AlMgSi alloy • Temper designation indicates thermal solutionizing and aging treatment to achieve strength • See www.matls.com for properties Properties (from www.matls.com) • • • • • • • Density = 2700 kg/m3 Yield strength = 275 MPa Tensile strength = 310 MPa Elongation = 12% Young’s Modulus = 69 GPa Poisson’s ratio = 0.33 Fatigue strength = 95 MPa @ N = 5 108 Fatigue failure • Fracture by cyclic stressing or straining • The amplitude of or for fatigue failure may be well below those for static failures • Fatigue process – Initiation of small cracks during “early” cycles – Propagation of cracks during subsequent cycles – Fracture Factors affecting fatigue • Surface finish (amount and direction) • Stress concentration or raisers • Internal metal defects (voids, cracks, inclusions) • Temperature • Size • Miscellaneous Effect of Geometry • Effect of geometry (i.e., a notch) is a “constraint” that favors higher stresses • Small cracks reduce area producing a higher stress • Stress concentration at the tip of small fissures provides a much greater influence • Actual stress can be several orders of magnitude larger than the applied stress Progress of fatigue failure From R.A. Higgins, Engineering Metallurgy Failure Surface Fatigue data • Plotted on S-N diagram S = stress or strain N = number of cycles • Fatigue is a statistical phenomenon with significant scatter • Ferrous alloys typically show a distinct fatigue limit, below which failure does not occur (roughly UTS/2) • Many non-ferrous alloys do not have a distinct fatigue limit Ferrous vs. non ferrous alloys From R.A. Huggins, Engineering Metallurgy Steel vs. Aluminum alloy From Manufacturing Processes for Engineering Materials, Kalpakjian High cycle fatigue • Greater than 103 cycles or more • Sensitive to surface quality • May involve little large scale plastic flow, characteristic of brittle fracture • Local crack propagation may involve a wide variety of ductile and brittle phenomena Specimen Bearing Set screw ø5.00 Cantilever arm Applied load + self loading weight 125.7 mm Experimental Apparatus 3 1 D C B 4 A 2 Calculations 125.7 P r 2 b = (N/mm ) I d 4 I = 64 1 applied b N a 0.81 2ultimate a endurance b 0.9 ultimate 1 log X endurance X 1 log[ N reference ] 2 8.40 Log (Applied stress) 8.35 8.30 8.25 y = -0.0977x + 8.8369 R2 = 1 8.20 8.15 8.10 8.05 8.00 0.00 1.00 2.00 3.00 4.00 5.00 6.00 Log (Cycles to Failure) 7.00 8.00 9.00 Lab Analysis and Report • Determine weight for each stress level • Predict N for each trial • Calculate mean and standard deviation for each data set • Perform Chauvenet’s criteria analyses • Plot bending stress vs. mean cycles to failure showing one standard deviation • Extrapolate endurance limit for N = 5 108 • Redo for r = 2.45 mm