Fatigue

advertisement

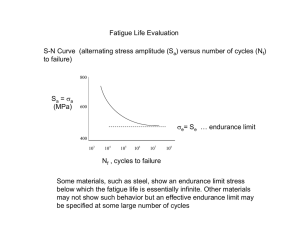

Fatigue of Materials Fatigue Definition: Damage accumulated through the application of repeated stress cycles Variable amplitude loadings cause different levels of fatigue Fatigue is cumulative through the life of an engineering element Factors Affecting Fatigue Life Loading Conditions Type of stress Stress amplitude, mean value Condition of Specimen/Structural Member Stress concentrations Surface finish Material Thermal history (e.g. grain size in metals) Environmental conditions Temperature Corrosion effects Loading Characteristics Effect of Mean Stresses sult sm=0 sa No mean stress sm>0 sa Mean Stresses reduce the stress range Stress Amplitude vs. Mean Goodman Relationship: lower the mean stresses, the greater the allowable stress amplitude for the same life. sa sm 1 s f su sa sf su sm Example: Goodman Diagram If sf=su/2, sm=su/2, What is the max and min s that can be applied? sa su/2sf smin= su/4 smax= 3su/4 su/4sf su/2sm su sm Stress vs. Number of Cycles S-N Diagram Lower mean stress Miner’s Rule Damage from variable loadings is related to the life consumed by number of cycles at each particular STRESS RANGE. The summation of life consumed at each stress range must be less than 1 to avoid failure. where: S ni/Nfi 1 = number of repetitions applied at si Nfi = number of repetitions to cause failure at a stress range, si (ni < Nfi) ni Example problem - Miner’s Rule Stress Range, si (ksi) No. Applied Cycles, Ni No. Cycles to Failure,Nfi 3 5 900 50 10,000 500 SNi/Nfi = 900/10,000 + 50/500 = 0.09 + 0.10 = 0.19 0.19 < 1.0 OK Used 19% of fatigue life, 81% remains 5 3 500 10,000 Log N Fatigue tests 1. Beam Fatigue 2. Tension- Compression V 3. Others M 2c smax = Mc/I M Loading Patterns: 1. Reverse stresses, + to 2. Alternate zero to some maximum 3. Alternate above some base value