Process Capability

advertisement

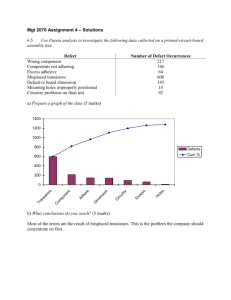

Chapter 9A Process Capability and SPC 9A-2 OBJECTIVES • Process Variation • Process Capability • Process Control Procedures – – Variable data Attribute data 9A-3 Basic Forms of Variation Assignable variation is caused by factors that can be clearly identified and possibly managed Common variation is inherent in the production process Example: A poorly trained employee that creates variation in finished product output. Example: A molding process that always leaves “burrs” or flaws on a molded item. 9A-4 Taguchi’s View of Variation Traditional view is that quality within the LS and US is good and that the cost of quality outside this range is constant, where Taguchi views costs as increasing as variability increases, so seek to achieve zero defects and that will truly minimize quality costs. High High Incremental Cost of Variability Incremental Cost of Variability Zero Zero Lower Target Spec Spec Upper Spec Traditional View Lower Spec Target Spec Upper Spec Taguchi’s View Process Capability • Process limits • Specification limits • How do the limits relate to one another? 9A-6 Process Capability Index, Cpk Capability Index shows how well parts being produced fit into design limit specifications. X LTL UTL - X C pk = min or 3 3 As a production process produces items small shifts in equipment or systems can cause differences in production performance from differing samples. Shifts in Process Mean 9A-7 Process Capability – A Standard Measure of How Good a Process Is. A simple ratio: Specification Width _________________________________________________________ Actual “Process Width” Generally, the bigger the better. 9A-8 Process Capability C pk X LTL UTL X Min ; 3 3 This is a “one-sided” Capability Index Concentration on the side which is closest to the specification - closest to being “bad” 9A-9 The Cereal Box Example • We are the maker of this cereal. Consumer reports has just published an article that shows that we frequently have less than 16 ounces of cereal in a box. • Let’s assume that the government says that we must be within ± 5 percent of the weight advertised on the box. • Upper Tolerance Limit = 16 + .05(16) = 16.8 ounces • Lower Tolerance Limit = 16 – .05(16) = 15.2 ounces • We go out and buy 1,000 boxes of cereal and find that they weight an average of 15.875 ounces with a standard deviation of .529 ounces. 9A-10 Cereal Box Process Capability • Specification or Tolerance Limits – Upper Spec = 16.8 oz – Lower Spec = 15.2 oz • Observed Weight – Mean = 15.875 oz – Std Dev = .529 oz C pk C pk X LTL UTL X Min ; 3 3 15.875 15.2 16.8 15.875 Min ; 3 (. 529 ) 3 (. 529 ) C pk Min.4253; .5829 C pk .4253 9A-11 What does a Cpk of .4253 mean? • An index that shows how well the units being produced fit within the specification limits. • This is a process that will produce a relatively high number of defects. • Many companies look for a Cpk of 1.3 or better… 6-Sigma company wants 2.0! 9A-12 Types of Statistical Sampling • Attribute (Go or no-go information) – – – Defectives refers to the acceptability of product across a range of characteristics. Defects refers to the number of defects per unit which may be higher than the number of defectives. p-chart application • Variable (Continuous) – – Usually measured by the mean and the standard deviation. X-bar and R chart applications Statistical Process Normal Behavior Control (SPC) Charts 9A-13 UCL LCL 1 2 3 4 5 6 Samples over time UCL Possible problem, investigate LCL 1 2 3 4 5 6 Samples over time UCL Possible problem, investigate LCL 1 2 3 4 5 6 Samples over time 9A-14 Control Limits are based on the Normal Curve x m -3 -2 -1 Standard deviation units or “z” units. 0 1 2 3 z 9A-15 Control Limits We establish the Upper Control Limits (UCL) and the Lower Control Limits (LCL) with plus or minus 3 standard deviations from some x-bar or mean value. Based on this we can expect 99.7% of our sample observations to fall within these limits. 99.7% LCL UCL x 9A-16 Example of Constructing a p-Chart: Required Data Sample No. of No. Samples 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 Number of defects found in each sample 4 2 5 3 6 4 3 7 1 2 3 2 2 8 3 9A-17 Statistical Process Control Formulas: Attribute Measurements (p-Chart) T o ta l N u m b e r o f D e fe c tiv e s Given: p = T o ta l N u m b e r o f O b s e rv a tio n s sp = p (1 - p) n Compute control limits: UCL = p + z sp LCL = p - z sp 9A-18 Example of Constructing a p-chart: Step 1 1. Calculate the sample proportions, p (these are what can be plotted on the p-chart) for each sample Sample 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 n Defectives 100 4 100 2 100 5 100 3 100 6 100 4 100 3 100 7 100 1 100 2 100 3 100 2 100 2 100 8 100 3 p 0.04 0.02 0.05 0.03 0.06 0.04 0.03 0.07 0.01 0.02 0.03 0.02 0.02 0.08 0.03 9A-19 Example of Constructing a p-chart: Steps 2&3 2. Calculate the average of the sample proportions 55 p = 1500 = 0.036 3. Calculate the standard deviation of the sample proportion sp = p (1 - p) = n .036(1- .036) = .0188 100 9A-20 Example of Constructing a p-chart: Step 4 4. Calculate the control limits UCL = p + z sp LCL = p - z sp .036 3(.0188) UCL = 0.0924 LCL = -0.0204 (or 0) 9A-21 Example of Constructing a p-Chart: Step 5 5. Plot the individual sample proportions, the average of the proportions, and the control limits 0.16 0.14 0.12 UCL 0.1 p 0.08 0.06 0.04 0.02 LCL 0 1 2 3 4 5 6 7 8 9 O b servation 10 11 12 13 14 15 9A-22 Example of x-bar and R Charts: Required Data Sample 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Obs 1 10.68 10.79 10.78 10.59 10.69 10.75 10.79 10.74 10.77 10.72 10.79 10.62 10.66 10.81 10.66 Obs 2 10.689 10.86 10.667 10.727 10.708 10.714 10.713 10.779 10.773 10.671 10.821 10.802 10.822 10.749 10.681 Obs 3 10.776 10.601 10.838 10.812 10.79 10.738 10.689 10.11 10.641 10.708 10.764 10.818 10.893 10.859 10.644 Obs 4 10.798 10.746 10.785 10.775 10.758 10.719 10.877 10.737 10.644 10.85 10.658 10.872 10.544 10.801 10.747 Obs 5 10.714 10.779 10.723 10.73 10.671 10.606 10.603 10.75 10.725 10.712 10.708 10.727 10.75 10.701 10.728 9A-23 Example of x-bar and R charts: Step 1. Calculate sample means, sample ranges, mean of means, and mean of ranges. Sample 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Obs 1 10.68 10.79 10.78 10.59 10.69 10.75 10.79 10.74 10.77 10.72 10.79 10.62 10.66 10.81 10.66 Obs 2 10.689 10.86 10.667 10.727 10.708 10.714 10.713 10.779 10.773 10.671 10.821 10.802 10.822 10.749 10.681 Obs 3 10.776 10.601 10.838 10.812 10.79 10.738 10.689 10.11 10.641 10.708 10.764 10.818 10.893 10.859 10.644 Obs 4 10.798 10.746 10.785 10.775 10.758 10.719 10.877 10.737 10.644 10.85 10.658 10.872 10.544 10.801 10.747 Obs 5 10.714 10.779 10.723 10.73 10.671 10.606 10.603 10.75 10.725 10.712 10.708 10.727 10.75 10.701 10.728 Averages Avg 10.732 10.755 10.759 10.727 10.724 10.705 10.735 10.624 10.710 10.732 10.748 10.768 10.733 10.783 10.692 Range 0.116 0.259 0.171 0.221 0.119 0.143 0.274 0.669 0.132 0.179 0.163 0.250 0.349 0.158 0.103 10.728 0.220400 9A-24 Example of x-bar and R charts: Step 2. Determine Control Limit Formulas and Necessary Tabled Values x Chart Control Limits UCL = x + A 2 R LCL = x - A 2 R R Chart Control Limits UCL = D 4 R LCL = D 3 R From Exhibit 9A.6 n 2 3 4 5 6 7 8 9 10 11 A2 1.88 1.02 0.73 0.58 0.48 0.42 0.37 0.34 0.31 0.29 D3 0 0 0 0 0 0.08 0.14 0.18 0.22 0.26 D4 3.27 2.57 2.28 2.11 2.00 1.92 1.86 1.82 1.78 1.74 9A-26 Example of x-bar and R charts: Steps 3&4. Calculate x-bar Chart and Plot Values UCL = x + A 2 R 10.728 - .58(0.2204 ) = 10.856 LCL = x - A 2 R 10.728 - .58(0.2204 ) = 10.601 10.900 UCL 10.850 M ean s 10.800 10.750 10.700 10.650 10.600 LCL 10.550 1 2 3 4 5 6 7 8 Sam ple 9 10 11 12 13 14 15 9A-27 Example of x-bar and R charts: Steps 5&6. Calculate R-chart and Plot Values UCL = D 4 R ( 2.11)(0.2204) 0.46504 LCL = D3 R (0)(0.2204) 0 0 .8 0 0 0 .7 0 0 0 .6 0 0 0 .5 0 0 R UCL 0 .4 0 0 0 .3 0 0 0 .2 0 0 0 .1 0 0 LCL 0 .0 0 0 1 2 3 4 5 6 7 8 S a m p le 9 10 11 12 13 14 15 9A-29 Question Bowl A methodology that is used to show how well parts being produced fit into a range specified by design limits is which of the following? a. Capability index b. Producer’s risk c. Consumer’s risk d. AQL e. None of the above Answer: a. Capability index 9A-30 Question Bowl You want to prepare a p chart and you observe 200 samples with 10 in each, and find 5 defective units. What is the resulting “fraction defective”? a. 25 b. 2.5 c. 0.0025 d. 0.00025 e. Can not be computed on data above Answer: c. 0.0025 (5/(2000x10)=0.0025) 9A-31 Question Bowl You want to prepare an x-bar chart. If the number of observations in a “subgroup” is 10, what is the appropriate “factor” used in the computation of the UCL and LCL? a. 1.88 b. 0.31 c. 0.22 d. 1.78 e. None of the above Answer: b. 0.31 9A-32 Question Bowl You want to prepare an R chart. If the number of observations in a “subgroup” is 5, what is the appropriate “factor” used in the computation of the LCL? a. 0 b. 0.88 Answer: a. 0 c. 1.88 d. 2.11 e. None of the above 9A-33 Question Bowl You want to prepare an R chart. If the number of observations in a “subgroup” is 3, what is the appropriate “factor” used in the computation of the UCL? a. 0.87 b. 1.00 c. 1.88 d. 2.11 e. None of the above Answer: e. None of the above 9A-34 End of Chapter 9A 1-34