Document

advertisement

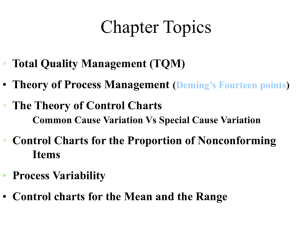

Using Control Charts to Keep an Eye on Variability Operations Management Dr. Ron Lembke Goal of Control Charts See if process is “in control” Process should show random values No trends or unlikely patterns Visual representation much easier to interpret Tables of data – any patterns? Spot trends, unlikely patterns easily NFL Control Chart? Control Charts Values UCL avg LCL Sample Number Definitions of Out of Control 1. 2. 3. 4. No points outside control limits Same number above & below center line Points seem to fall randomly above and below center line Most are near the center line, only a few are close to control limits 1. 2. 3. 8 Consecutive pts on one side of centerline 2 of 3 points in outer third 4 of 5 in outer two-thirds region Control Charts Normal 5 above, or below Too Low Too high Run of 5 Extreme variability Control Charts UCL 2σ 1σ avg 1σ 2σ LCL Control Charts 2 out of 3 in the outer third Out of Control Point? Is there an “assignable cause?” If not usual variability, GET IT OUT Or day-to-day variability? Remove data point from data set, and recalculate control limits If it is regular, day-to-day variability, LEAVE IT IN Include it when calculating control limits Attributes vs. Variables Attributes: Good / bad, works / doesn’t count % bad (P chart) count # defects / item (C chart) Variables: measure length, weight, temperature (x-bar chart) measure variability in length (R chart) p Chart Control Limits UCL p p z sp LCL p p z sp z = 2 for 95.5% limits z = 3 for 99.7% limits p = avg defect rate n = avg sample size sp = sample std dev k k sp p (1 p ) n n n i 1 k # Samples i X p i i 1 k n i 1 i # Defective Items in Sample i Sample i Size p Chart Example You’re manager of a 1,700 room hotel. For 7 days, you collect data on the readiness of all of the rooms that someone checked out of. Is the process in control (use z = 3)? © 1995 Corel Corp. p Chart Hotel Data Day 1 2 3 4 5 6 7 # Rooms n 1,300 800 400 350 300 400 600 No. Not Proportion Ready p 130 130/1,300 =.100 90 .113 21 .053 25 .071 18 .06 12 .03 30 .05 p Chart Control Limits k n n i i 1 1300 800 ... 600 k 4 ,150 7 592 . 8 7 k p Xi i 1 k n 130 90 ... 30 4 ,150 326 0 . 079 4 ,150 i i 1 p ( 0 . 10 0 . 113 ... 0 . 05 ) / 7 . 068 p Chart Solution p 0 . 079 , sp n 592 . 8 p 1 p n 0 . 079 1 0 . 079 592 . 8 CL p z s p 0 . 079 3 * 0 . 111 0 . 079 0 . 0333 UCL 0 . 1123 , LCL 0 . 0457 0 . 0111 Hotel Room Readiness P-Bar 0.12 0.1 0.08 UCL 0.06 Actual LCL 0.04 0.02 0 1 2 3 4 5 6 7 R Chart Type of variables control chart Shows sample ranges over time Interval or ratio scaled numerical data Difference between smallest & largest values in inspection sample Monitors variability in process Example: Weigh samples of coffee & compute ranges of samples; Plot Why do we need 2 charts? Consistent, but the average is in the wrong place UCL UCL LCL LCL X-Bar Chart R Chart The average works out ok, but way too much variability between points UCL UCL LCL LCL X-Bar Chart R Chart Hotel Example You’re manager of a 500room hotel. You want to analyze the time it takes to deliver luggage to the room. For 7 days, you collect data on 5 deliveries per day. Is the process in control? Hotel Data Day Delivery Time 1 7.30 4.20 6.10 3.45 2 4.60 8.70 7.60 4.43 3 5.98 2.92 6.20 4.20 4 7.20 5.10 5.19 6.80 5 4.00 4.50 5.50 1.89 6 10.10 8.10 6.50 5.06 7 6.77 5.08 5.90 6.90 5.55 7.62 5.10 4.21 4.46 6.94 9.30 R &X Chart Hotel Data Day Delivery Time 1 7.30 4.20 6.10 3.45 5.55 Sample Mean Range 5.32 7.30 + 4.20 + 6.10 + 3.45 + 5.55 Sample Mean = 5 R &X Chart Hotel Data Day Delivery Time 1 7.30 4.20 6.10 3.45 5.55 Largest Smallest Sample Mean Range 5.32 3.85 Sample Range = 7.30 - 3.45 R &X Chart Hotel Data Day 1 7.30 2 4.60 3 5.98 4 7.20 5 4.00 6 10.10 7 6.77 Delivery Time 4.20 6.10 3.45 8.70 7.60 4.43 2.92 6.20 4.20 5.10 5.19 6.80 4.50 5.50 1.89 8.10 6.50 5.06 5.08 5.90 6.90 5.55 7.62 5.10 4.21 4.46 6.94 9.30 Sample Mean Range 5.32 3.85 6.59 4.27 4.88 3.28 5.70 2.99 4.07 3.61 7.34 5.04 6.79 4.22 R Chart Control Limits U C LR D 4 R Table 10.3, p.433 L C LR D 3 R k Ri R i 1 k Sample Range at Time i # Samples Control Chart Limits n A2 D3 D4 2 1 .8 8 0 3 .2 7 8 3 1 .0 2 0 2 .5 7 4 0 .7 3 0 2 .2 8 5 0 .5 8 0 2 .1 1 6 0 .4 8 0 2 .0 0 7 0 .4 2 0 .0 8 1 .9 2 R Chart Control Limits k R Ri i 1 k 3 . 85 4 . 27 ... 4 . 22 3 . 894 7 UCL R D 4 * R 2 . 11 * 3 . 894 8 . 232 LCL R D 3 * R 0 * 3 . 894 0 D 3 , D 4 from Table 10.3 R Chart Solution 9 8 7 6 5 UCL Range LCL 4 3 2 1 0 1 2 3 4 5 6 7 X Chart Control Limits UCL X A2 R X Sample Mean at Time i k X i 1 k k R Xi R i 1 k i Sample Range at Time i # Samples X Chart Control Limits A2 from Table 10-3 UCL X X A2 R LCL X X A2 R k X X i 1 k k R i R i 1 k i Control Chart Limits n A2 D3 D4 2 1 .8 8 0 3 .2 7 8 3 1 .0 2 0 2 .5 7 4 0 .7 3 0 2 .2 8 5 0 .5 8 0 2 .1 1 6 0 .4 8 0 2 .0 0 7 0 .4 2 0 .0 8 1 .9 2 R &X Chart Hotel Data Day 1 7.30 2 4.60 3 5.98 4 7.20 5 4.00 6 10.10 7 6.77 Delivery Time 4.20 6.10 3.45 8.70 7.60 4.43 2.92 6.20 4.20 5.10 5.19 6.80 4.50 5.50 1.89 8.10 6.50 5.06 5.08 5.90 6.90 5.55 7.62 5.10 4.21 4.46 6.94 9.30 Sample Mean Range 5.32 3.85 6.59 4.27 4.88 3.28 5.70 2.99 4.07 3.61 7.34 5.04 6.79 4.22 X Chart Control Limits k Xi i 1 X k 5 . 32 6 . 59 ... 6 . 79 5 . 813 7 k R i 1 R k i 3 . 85 4 . 27 ... 4 . 22 3 . 894 7 UCL X X A 2 * R 5 . 813 0 . 58 * 3 . 894 8 . 060 LCL X X A 2 * R 5 . 813 0 . 58 * 3 . 894 3 . 566 X Chart Solution* 9 8 7 6 5 UCL Mean LCL 4 3 2 1 0 1 2 3 4 5 6 7 Summary Overview of “In Control” Attribute vs Continuous Control Charts P Charts X-bar and R charts