Laser Distance Meter- San Diego Poster Final

advertisement

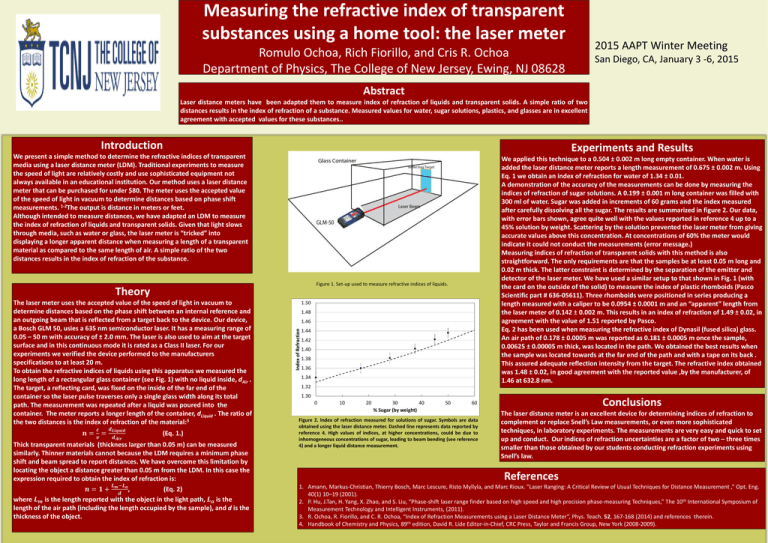

Measuring the refractive index of transparent substances using a home tool: the laser meter 2015 AAPT Winter Meeting Romulo Ochoa, Rich Fiorillo, and Cris R. Ochoa Department of Physics, The College of New Jersey, Ewing, NJ 08628 San Diego, CA, January 3 -6, 2015 Abstract Laser distance meters have been adapted them to measure index of refraction of liquids and transparent solids. A simple ratio of two distances results in the index of refraction of a substance. Measured values for water, sugar solutions, plastics, and glasses are in excellent agreement with accepted values for these substances.. Introduction Experiments and Results We present a simple method to determine the refractive indices of transparent media using a laser distance meter (LDM). Traditional experiments to measure the speed of light are relatively costly and use sophisticated equipment not always available in an educational institution. Our method uses a laser distance meter that can be purchased for under $80. The meter uses the accepted value of the speed of light in vacuum to determine distances based on phase shift measurements. 1-2The output is distance in meters or feet. Although intended to measure distances, we have adapted an LDM to measure the index of refraction of liquids and transparent solids. Given that light slows through media, such as water or glass, the laser meter is “tricked” into displaying a longer apparent distance when measuring a length of a transparent material as compared to the same length of air. A simple ratio of the two distances results in the index of refraction of the substance. Figure 1. Set-up used to measure refractive indices of liquids. Theory 𝒏= = 𝒅𝑳𝒊𝒒𝒖𝒊𝒅 𝒅𝑨𝒊𝒓 (Eq. 1.) Thick transparent materials (thickness larger than 0.05 m) can be measured similarly. Thinner materials cannot because the LDM requires a minimum phase shift and beam spread to report distances. We have overcome this limitation by locating the object a distance greater than 0.05 m from the LDM. In this case the expression required to obtain the index of refraction is: 𝑳𝒎 −𝑳𝒂 𝒏=𝟏+ , (Eq. 2) 𝒅 where 𝑳𝒎 is the length reported with the object in the light path, 𝑳𝒂 is the length of the air path (including the length occupied by the sample), and d is the thickness of the object. 1.50 1.48 1.46 Index of Refraction The laser meter uses the accepted value of the speed of light in vacuum to determine distances based on the phase shift between an internal reference and an outgoing beam that is reflected from a target back to the device. Our device, a Bosch GLM 50, usies a 635 nm semiconductor laser. It has a measuring range of 0.05 – 50 m with accuracy of ± 2.0 mm. The laser is also used to aim at the target surface and in this continuous mode it is rated as a Class II laser. For our experiments we verified the device performed to the manufacturers specifications to at least 20 m. To obtain the refractive indices of liquids using this apparatus we measured the long length of a rectangular glass container (see Fig. 1) with no liquid inside, dAir . The target, a reflecting card, was fixed on the inside of the far end of the container so the laser pulse traverses only a single glass width along its total path. The measurement was repeated after a liquid was poured into the container. The meter reports a longer length of the container, dLiquid . The ratio of the two distances is the index of refraction of the material:3 𝒄 𝒗 We applied this technique to a 0.504 ± 0.002 m long empty container. When water is added the laser distance meter reports a length measurement of 0.675 ± 0.002 m. Using Eq. 1 we obtain an index of refraction for water of 1.34 ± 0.01. A demonstration of the accuracy of the measurements can be done by measuring the indices of refraction of sugar solutions. A 0.199 ± 0.001 m long container was filled with 300 ml of water. Sugar was added in increments of 60 grams and the index measured after carefully dissolving all the sugar. The results are summarized in figure 2. Our data, with error bars shown, agree quite well with the values reported in reference 4 up to a 45% solution by weight. Scattering by the solution prevented the laser meter from giving accurate values above this concentration. At concentrations of 60% the meter would indicate it could not conduct the measurements (error message.) Measuring indices of refraction of transparent solids with this method is also straightforward. The only requirements are that the samples be at least 0.05 m long and 0.02 m thick. The latter constraint is determined by the separation of the emitter and detector of the laser meter. We have used a similar setup to that shown in Fig. 1 (with the card on the outside of the solid) to measure the index of plastic rhomboids (Pasco Scientific part # 636-05611). Three rhomboids were positioned in series producing a length measured with a caliper to be 0.0954 ± 0.0001 m and an “apparent” length from the laser meter of 0.142 ± 0.002 m. This results in an index of refraction of 1.49 ± 0.02, in agreement with the value of 1.51 reported by Pasco. Eq. 2 has been used when measuring the refractive index of Dynasil (fused silica) glass. An air path of 0.178 ± 0.0005 m was reported as 0.181 ± 0.0005 m once the sample, 0.00625 ± 0.00005 m thick, was located in the path. We obtained the best results when the sample was located towards at the far end of the path and with a tape on its back . This assured adequate reflection intensity from the target. The refractive index obtained was 1.48 ± 0.02, in good agreement with the reported value ,by the manufacturer, of 1.46 at 632.8 nm. 1.44 1.42 1.40 1.38 1.36 1.34 1.32 1.30 0 10 20 30 40 % Sugar (by weight) 50 Conclusions 60 Figure 2. Index of refraction measured for solutions of sugar. Symbols are data obtained using the laser distance meter. Dashed line represents data reported by reference 4. High values of indices, at higher concentrations, could be due to inhomogeneous concentrations of sugar, leading to beam bending (see reference 4) and a longer liquid distance measurement. The laser distance meter is an excellent device for determining indices of refraction to complement or replace Snell’s Law measurements, or even more sophisticated techniques, in laboratory experiments. The measurements are very easy and quick to set up and conduct. Our indices of refraction uncertainties are a factor of two – three times smaller than those obtained by our students conducting refraction experiments using Snell’s law. References 1. Amann, Markus-Christian, Thierry Bosch, Marc Lescure, Risto Myllyla, and Marc Rioux. ”Laser Ranging: A Critical Review of Usual Techniques for Distance Measurement ,” Opt. Eng. 40(1) 10–19 (2001). 2. P. Hu, J.Tan, H. Yang, X. Zhao, and S. Liu, “Phase-shift laser range finder based on high speed and high precision phase-measuring Techniques,” The 10th International Symposium of Measurement Technology and Intelligent Instruments, (2011). 3. R. Ochoa, R. Fiorillo, and C. R. Ochoa, “Index of Refraction Measurements using a Laser Distance Meter”, Phys. Teach. 52, 167-168 (2014) and references therein. 4. Handbook of Chemistry and Physics, 89th edition, David R. Lide Editor-in-Chief, CRC Press, Taylor and Francis Group, New York (2008-2009).