TQM_ Continuous Process Improvement

advertisement

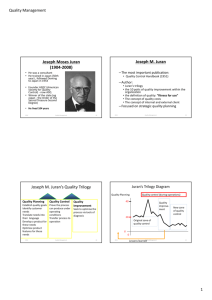

Continuous Process Improvement Achieve Perfection Work as Process to make it Effective, Efficient, and Adaptable Changing Customer Needs Control in process-Reduce Scrap, Time, Idle of Resources Eliminate Non Conformance in All Phases Bench Marking Innovation Statistical Tools, QFD,FMEA. Taguchi Loss Function 1 Types of Problems • • • • • Compliance Unstructured Efficiency Process Design Product Design 2 Shewhart’s PDSA CYCLE in 1930 • • • • PLAN DO STUDY ACT ACT STUDY PLAN DO 3 Continuous Process Improvement Cycle Phase 1 Identify the opportunity Phase 7Plan for the Future Phase 6 Standardize the Solution Phase 5 Study the Results Phase 2 Analyze the Process ACT STUDY PLAN Phase 3 Develop the Optimal Solution DO Phase 4 Implementation 4 5 The Deming Cycle or PDCA Cycle PLAN ACT Plan a change to the process. Predict the effect this change will have and plan how the effects will be measured Adopt the change as a permanent modification to the process, or abandon it. DO Implement the change on a small scale and measure the effects CHECK Study the results to learn what effect the change had, if any. 6 Kaoru Ishikawa has expanded Deming's four steps into six: Determine goals and targets. Determine methods of reaching goals. Engage in education and training. Implement work. Check the effects of implementation. Take appropriate action. 7 Juran's Trilogy Juran's Trilogy is possibly the most simple, complete, and pure representation of managing for Quality ever devised. The trilogy exemplifies the essence of Quality. It completely meets its objective in the most efficient and effective manner possible 8 Juran's Trilogy Quality Planning Identify the Customers Determine the customer’ needs Develop a process Prove process capability 9 Juran's Trilogy Quality Control Choose control Subjects (What to Control) Choose Units of measurements Establish Measurement Establish Standards of performance Measure actual performance Interpret the difference Take action on the difference 10 Juran's Trilogy Quality Improvement Prove need for improvement Identify specific projects for Improvements Organize to guide & Diagnosis To find causes Provide Remedies Prove remedies for effective in operating conditions Control the gains 11 JURAN’S QUALITY TRIOLOGY Cost of Quality Quality Planning Threshold Of Plan Quality Improvement Initial Quality Zone Chronic Waste (An opportunity For Improvement) Quality Control Breakthrough Quality Zone Time 12 Juran’s Spiral of Progress in Quality Marketing Operation Customers Further Product Development Customers Product Development 13 Quality Improvement Strategies • • • • Repair Refinement Renovation Reinvention 14 KAI Change ZEN Good (for the better) 15 KAIZEN = Continual Improvement KAIZEN Umbrella-Continuous Improvement • • • • • • • • Customer Orientation 5S TQC Zero Defect TPM QC’s JIT Quality Improvements 16 Japanese Mgt Functions and Kaizen TOP Mgt Innovation Middle Mgt Supervisors Maintenance Workers 17 Japanese Vs Western Approach KAIZEN INNOVATION JAPAN Strong Weak WEST Weak Strong 18 Kaizen Implementation • Discard Conventional ideas • Think in Positive Manner • Do not make excuses but question Current Practice • Correct Mistakes at once • Problem Solving & Find Root Causes • Team Work To achieve MAXIMUM • Meeting of Kaizen group once in Month 19 TOTAL MANUFACTURING CHAIN SCIENCE TECHNOLOGY INNOVATION DESIGN PRODUCTION MARKET KAIZEN 20 Comparison of INNOVATION & KAIZEN INNOVATION KAIZEN Creavitivity Adaptability Individualism Team Work Technology Information- Closed Seeks New Technology People- oriented Information-Open Builds on Existing Technology Comprehensive Feedback Limited Feedback 21 3-MU’s Checklist of Kaizen Activities Muda (Waste) Muri (Strain) Mura (Discrepancy) Man Power Man Power Man Power Technique Technique Technique Method Method Method Time Time Time Materials Materials Materials Inventory Inventory Inventory Way of Thinking Way of Thinking Way of Thinking 22 • In an Organization, Kaizen activities will be carried out by asking the Questions-Who, Where, When, Why, and How • Eg-Who does it? What to do? Where to do it? When to do it? Why to do it? How to do it? 23 5S 24 Throw Every Where Never Throw ? Never Clean Always Clean 1st Class Work Place 3 rd Class Work Place HOUSE KEEPING_5-S MODEL 25 Better Tomorrow for Everyone Ultimate Goal Effective Use Resources Efficiency Improvement Economic Operation Intermediate Goal Approach & Method Foundation J I T T Q C T P M T Q M 5S 5 S FOUNDATION FOR PRODUCTIVITY IMPROVEMENT 26 27 SEI-RI-Clearing Up • Identification of materials, equipment and tools data which are necessary or not necessary, discarding and make space for the required one’s. 28 29 SEI-TON = ORGANIZING • Once Cleaned and then arrange them in orderly manner. • People should cultivate the habit of return the tools to the place from where it was taken. • Easily accessible • Reduces time and confusions • Improves Efficiency 30 31 SEI-SO= CLEANING • After Clearing & Arranging . • Organization should Identify and Eliminate source of Dirt, Dust, (or) Trash • Update Constantly 32 33 SEI-KE-TSU=Personal Cleanliness • Good Working Condition and Personal Hygiene • Clean Person is conscious of his Work Place • Good Sanitary Condition 34 SHI-TSU-KE =Self Discipline • Not only Job Related but also Personally it is important. • Job Discipline is the habit of Skill Development to do work as per Standards. • Observe Rules & Policies of the Company 35 36 37