This Document

advertisement

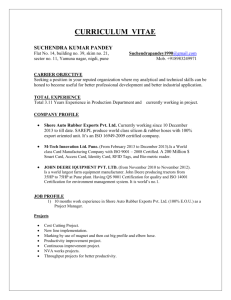

Joseph McGeown j_mcgeown@hotmail.com Tel –Home 01494 265745 Tel- mob 07760 881589 76 walton drive High wycome hp13 6tt Profile An Area Manager|Managing Director | Operations Director | Process Improvement professional with the commercial diligence and change management expertise to implement lean manufacturing across time, cost, quality and service critical retail, print and manufacturing environments Holds a consistent record of implementing strategies and developing cutting-edge operational improvements to leverage business growth,productivity and market position in global markets. A perceptive communicator, able to engage and build relationships with clients, management, partners and suppliers, and lead and energise high calibre, cross-discipline teams to achieve first rate results – Now seeking a Challenging Senior-level Role Specialities Process Improvement Leadership Supplier Management TPM, TPS,5s, Kaizen, FMEA,JIT SPC, Kanban, SMED Change Control BS14001 Value Stream Mapping Production Planning Client Engagement Digital & Web Offset Print + ISO 9001 Quality Finishing Testimonial “To successfully design, implement, monitor and continually evolve processes and systems to improve workflow and efficiencies requires knowledge, experience and very specific skills. If a person cannot take the workforce with him on that journey then the above qualities are of little use. Joseph has no such worries, he is able to communicate effectively at all levels and was key in ensuring quality and output improvements demanded by the Directors were achieved and with ‘buy in’ from the workforce.” Alan Outlaw, Sales & Customer Services Director, Wyndeham Linkedin profile- http://www.linkedin.com/pub/joseph-mcgeown/6/93a/204Career July 2014-present Vice President of operations syncoms.co.uk www.syncoms.co.uk Leading the operations functions of this manufacturing and communications company July 2012 to date- Vistaprint BV www.vistaprint.com Process Improvement Leader / promoted to Value stream Manager / Promoted to Operations Head Of Lean | Venlo The Netherlands Currently Contributing to the expansion and profitability of this global on-line print and marketing manufacturer through the continuous improvement of processes and operational Support to various value streams Jan 2012 to July 2012- Jordan plastics Interim Managing Director www.Jordanplastics.com | Portadown Northern Ireland Overseeing the turn around and Developing the strategy to move back to profitability of this Flexible print and finishing manufacturer representing the Board of directors as Site General Manager Improved machine speeds and output by 38% in first two months Forecasted loss of 225k reduced to 70k in first three months Introduced short interval control to all machines reducing downtime and improving quality and speeds Oversee the day to day running of the Plant including P&L 2010 to Jan 2012 Amazon.co.uk Area Manager | www.Amazon.co.uk | Scotland / Peterborough Contributing to the expansion and profitability of this global on-line retailer - music, books, DVDs, video games, cameras, home and garden products - through the continuous improvement and operational management of inbound, outbound and returns for the UK. peak Personnel: 350 Increased productivity 100% by facilitation of Kaizen event designed to optimise line layout and throughput Recruited, trained and performance managed 100+ flexible staff to meet peak customer demand Implemented standard work as part of global strategy Lead Two large scale Kaizen events resulting in the adoption of new global standard work processes across the business and multiple local process changes Instilled a high quality, best practice team culture to put pride back into the Centre 2008 - 2010 quality and Bezier Limited Operations Director/Interim General Manager | www.bezier.com | Thurrock Held budgetary responsibility for management of the manufacturing, customer service, engineering functions within this print firm. T/o £26M Personnel: 90 Increased capacity 100% through installation of new press and finishing equipment Closed the Bristol facility and integrated £13M contracts – ahead of schedule and within budget Managed union negotiations and introduced night shift working at no additional cost Saved £150K via headcount reduction and introduction of flexible working at favourable rates Saved £100K through renegotiation of new supplier material and sundry rates Developed KPIs, reports and graphs to present KPI data that was adopted as site standard Recruited and leveraged the capabilities of a talented Senior Management Team Re-planned and streamlined factory workflow and rolled out new, more efficient layout Implemented a new MIS system on-time and within budget Ensured robust compliance with site health and safety policies and procedures Achieved gold standard for health and safety for the site 2006 - 2008 Wyndeham Heron Limited |www.wyndeham.co.uk | Essex Site Operations Manager Press Operations Manager Manufacturing Improvements Manager Enjoyed rapid career progression in one of the UK’s premier web offset super plant producing prestigious consumer and business magazines and commercial print for blue chips, household names and businesses throughout the UK and Europe. T/o £40M+ Personnel: 350 Improved on-time delivery from -90% to 97% within 5 months Cut logistics costs 30% by reduced reliance on ‘same day’ deliveries Cut pressroom and bindery downtime 35% and 50% via PPM programme Reduced complaints 50% through TQM and customer care initiatives Increased capacity, output and profit through robust waste management controls Brought outsourced work in-house to reduce spend from £81k/month to £7k/month Met stretching production targets for OTIF in a fast-paced, quick turnaround environment Implemented KPIs and site performance monitoring - improving machine and people efficiency Provided direction and leadership to a team of 10 Performance Managers and an Improvement Manager responsible for production, engineering and paper departments Streamlined sections of the factory layout, improving production processes and output Facilitated training needs analysis of operations and managers resulting in site training plan 2003 - 2006 Polestar Group Colchester |www.polestar-group.com | Kaizen Engineer Headed a team of continuous improvement engineers within this web offset and gravure printing company, producing prestige magazine, catalogue, journal and direct mail clients across multiple European markets. T/o £46M Personnel: 200+ Delivered OTIF from 58% to 98% and increased output <20% via introduction of 3 workgroups, each with a continuous improvement ethic Devised a process to capture machine faults and cut resolution times from 3 weeks to 5 days Reduced make ready times from 3 hrs to 45 mins – improving service (£500k potential saving) Cut production costs and increased capacity and profit margin through elimination of waste Implemented new safety working practices and safety audits to reduce LTAs Nominated for ‘Unsung Hero of the Year’ Award 2006 from 5000 employees across 16 factories – a first nomination for a non-sales or print operations employee 2002 - 2003 Pressroom operator | BGP |Colchester 2000 - 2002 Pressroom Assistant | Ancient House Press | Ipswich Qualifications Fellowship in Lean Manufacturing Lancashire Institute for Leadership & Management Certificate Cert Management Systems Auditor NVQ Health and Safety Leadership | University of Continuing Professional Development Kaizen, 5s, FMEA, SPC, Kanban, SMED, Value Stream Mapping, OEE, TPM Discipline & Grievance, Absence Management, Recruitment & Selection Dealing with conflict, Restructuring & Redundancy, Trade Unions Performance Management, Performance Appraisals, Equality & Diversity Advanced cGMP, Change Control, HSE for Line Managers, QA Change Control Permit to Work, QA Deviation/CAR/QSI. COSHH Assessment. Quality Systems Change Management, TQM, Budget Management, Production Planning, ISO9001, Autonomous Maintenance, Target Setting Workshops, Coaching for Development, Emergency First Responder IT Skills Membership Interests MS Office: Word, Excel, PowerPoint, Front Page, HTML (Web Design) PADI Scuba Diver Association: Professional Divemaster and rescue diver Travel, playing the guitar, family and friends Central