Quantifying Sustainable Development with Sustainable Costs in the

advertisement

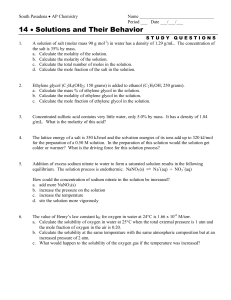

Integrating Bioprocesses into Industrial Complexes for Sustainable Development CO2 Debalina Sengupta Department of Chemical Engineering, Louisiana State University Introduction • • • • • • • Sustainable Development Overview Biomass conversion designs Superstructure formulation Optimal complex Case studies Conclusions Sustainability “Sustainable development is development that meets the needs of the present without compromising the ability of future generations to meet their own needs.” – Brundtland Report, United Nations There are numerous approaches to apply sustainable development by world organizations, countries and industries. Life Cycle Assessment (LCA) Eco-Efficiency Analysis Sustainability Indicators: Metrics and Indices Industrial Ecology Carbon Dioxide Sequestration (CCS, bio-sequestration, chemical sequestration) Total Cost Assessment Methodology (TCA) (Economic Costs, Environmental Costs, Societal Costs) AIChE Total Cost Assessment Methodology • Methodology developed by an industry group • Assesses economic, environmental and societal costs • Detailed report on total cost assessment (Constable et al., 1999). • Project Team AD Little (Collab. & Researcher) DOE Eastman Chemical Georgia Pacific Merck Owens Corning SmithKline Beecham (Lead) Bristol-Myers Squibb Dow Eastman Kodak IPPC of Business Round Table Monsanto Rohm and Haas Sylvatica (TCAce Dev.) • TCA Users Group created in May 2009. Work is ongoing to update the costs identified in the report. Constable, D. et al., “Total Cost Assessment Methodology; Internal Managerial Decision Making Tool”, AIChE, ISBN 0-81690807-9, July ,1999. Corporate Sustainability • A company’s success depends on maximizing profit Profit = Product Sales – Raw Material Costs – Energy Costs • The profit equation expanded to include environmental costs and societal costs to meet the “Triple Bottomline” criteria Triple Bottom Line = Product Sales + Sustainable Credits – Raw Material Costs – Energy Costs – Environmental Costs – Sustainable Costs Triple Bottom Line = Profit - Environmental Costs + Sustainable (Credits – Costs) Industries in Louisiana • Petrochemical complex in the lower Mississippi River Corridor – – – – – – – – Dow DuPont BASF Shell Exxon Monsanto Mosaic Union Carbide …. and others Photo: Peterson, 2000 Objectives of Research • Identify and design new industrial scale bioprocesses that use renewable feedstock as raw materials with Aspen HYSYS® • Construct block models of bioprocesses for optimization • Integrate new bioprocesses into a base case of existing plants to form a superstructure of plants (using the chemical production complex in the Lower Mississippi River Corridor) • Optimize the superstructure based on triple bottomline • Obtain the optimal configuration of existing and new plants (chemical complex optimization) • Demonstrate use of the superstructure for parametric studies Overview • Biomass based processes integrated into a chemical production complex. • Utilize carbon dioxide from processes in the integrated complex. • Assign costs to the Triple Bottomline Equation. • Mixed Integer Non-Linear Programming problem – – – – maximize the Triple Bottomline multiplant material and energy balances product demand and raw material availability plant capacities • Chemical Complex Analysis System used to obtain optimal solution to the MINLP problem (including Pareto optimal sets) • Monte Carlo simulation used to determine sensitivity of optimal solution to price of raw materials and products Biomass Processes Biomass conversion processes designed for integration into the chemical complex – – – – – Fermentation Anaerobic digestion Transesterification Gasification Algae oil production Pretreatment of biomass is needed to make feedstock available for conversion to products Aspen HYSYS® - Process simulation Aspen ICARUS Process Evaluator® - Cost Estimation Glycerol derivatives Proposed Biomass-Based Complex Extension Glycerol 1,3- propanediol Propylene glycol Natural Oils Transesterification Polyurethane polyols FAME or FAEE Ethanol Methanol Sugars Ethanol derivatives Fermentation Ethanol Ethylene Ethylene derivatives C6 Sugars Starches Cellulose and Hemicellulose Enzyme Conversion C5/C6 Sugars Succinic Acid Succinic acid derivatives Butanol Butanol derivatives Levulinic Acid Levulinic acid derivatives Acid or Enzyme Hydrolysis Acid dehydration Carbon Nanotubes Single Walled CNT Ammonia Ammonia derivatives Syngas Gasification Anaerobic Biodigestion Methanol Methanol derivatives Acetic Acid Acetic acid derivatives CH4 Design Description of Transesterification 4250 kg/hr Glycerol Natural Oils 393 kg/hr 4250 kg/hr Methanol Transesterification Thermodynamic model UNIQUAC Reactants Methanol Soybean Oil Catalyst 1.78% (w/w) Sodium Methylate in methanol Products Methyl Ester Glycerol Temperature 60oC FAME or FAEE 612 kg/hr • Transesterification 10 million gallons per year 1 of Fatty Acid Methyl Ester (FAME) produced Methyl Ester Purification • FAME is utilized in manufacture of polymers • Glycerol is used in manufacture of propylene glycol 1 Design Wash agents Water HCl Glycerol Recovery and Purification Purification Agents NaOH Water HCl based on “A process model to estimate biodiesel production costs”,M.J. Haas et al., Bioresource Technology 97 (2006) 671-678 HYSYS Design of Transesterification Process Transesterification Reaction Methyl ester purification Glycerol recovery and purification Design description of Propylene Glycol 246 kg/hr Hydrogen, 200oC, 200 psi Glycerol Propylene Glycol 9,300 kg/hr 15,000 kg/hr • The design is based on a process for hydrogenation of glycerol to propylene glycol 1 • ~65,000 metric ton of propylene glycol is produced per year2 1 Design 2 Hydrogenolysis Thermodynamic model UNIQUAC Reactants Glycerol Hydrogen Catalyst Copper Chromite Products Propylene Glycol Water Temperature 200oC Pressure 200 psi based on experimental results from Dasari, M. A. et al. 2005, Applied Catalysis, A: General, Vol. 281, p. 225-231. Capacity based on Ashland/Cargill joint venture of process converting glycerol to propylene glycol HYSYS Design of Glycerol to Propylene Glycol Hydrogenolysis Reaction Purification of Propylene Glycol Process Flow Design to Block Flow Model for Optimization S3001 S3020 S3002 S3003 S3021 TRANSESTERIFICATION S3004 S3022 S3005 S3023 S3006 Biomass-Based Complex Extension Base Case of Plants in the Lower Mississippi River Corridor Plants in the Base Case • • • • • • • • • • • • • Ammonia Nitric acid Ammonium nitrate Urea UAN Methanol Granular triple super phosphate MAP & DAP Sulfuric acid Phosphoric acid Acetic acid Ethylbenzene Styrene Integrated Chemical Production Complex Hydrogen,CO2 Biomass Complex Air, Methanol, Ammonia Base Case Complex Superstructure Profit Chemicals like methylamines, methanol, acetic acid etc. from CO2 CO2 Algae growth for use as biomass Triple Bottom Line = Profit - Environmental Costs + Sustainable (Credits – Costs) Superstructure Continuous Variables: 969 Integer Variables: 25 Equality Constraints: 978 Inequality Constraints: 91 Plants in Base Case (blue) Ammonia Nitric acid Ammonium nitrate Urea UAN Methanol Granular triple super phosphate (GTSP) MAP and DAP Contact process for sulfuric acid Wet process for phosphoric acid Acetic acid – conventional method Ethyl benzene Styrene Power generation Plants Added to Form the Superstructure Bioprocesses and CO2 consumption by Algae (green) Fermentation ethanol (corn stover) Fermentation ethanol (corn) Anaerobic Digestion to acetic acid (corn stover) Algae Oil Production Transesterification to FAME and glycerol (soybean oil and algae) Gasification to syngas (corn stover) Ethylene from dehydration of ethanol Propylene glycol from glycerol CO2 consumption for Chemicals (red) Methanol – Bonivardi, et al., 1998 Methanol – Jun, et al., 1998 Methanol – Ushikoshi, et al., 1998 Methanol – Nerlov and Chorkendorff, 1999 Ethanol Dimethyl ether Formic acid Acetic acid - new method Styrene - new method Methylamines Graphite Hydrogen/Synthesis gas Propylene from CO2 Propylene from propane dehydrogenation Choice for phosphoric acid production and SO2 recovery (yellow) Electric furnace process for phosphoric acid Haifa process for phosphoric acid SO2 recovery from gypsum waste S and SO2 recovery from gypsum waste Optimization Problem Maximize: Triple Bottom Line Triple Bottom Line = Profit - Environmental Costs + Sustainable (Credits – Costs) Subject to: Multiplant material and energy balance Product demand Raw material availability Plant capacities Optimal structure obtained by using Global Optimizers Optimal Solution Existing Plants in the Optimal Structure Ammonia Nitric acid Ammonium nitrate Urea UAN Methanol Granular triple super phosphate (GTSP) MAP and DAP Contact process for Sulfuric acid Wet process for phosphoric acid Power generation Existing Plants Not in the Optimal Structure Acetic acid Ethylbenzene Styrene New Plants in the Optimal Structure Fermentation to ethanol (corn) Bio-ethylene from dehydration of bio-ethanol Transesterification to FAME and glycerol (soy oil and algae) Algae oil production Bio-propylene glycol from glycerol Gasification to syngas (corn stover) Formic acid Graphite Propylene from CO2 Propylene from propane dehydrogenation New Plants Not in the Optimal Structure Fermentation to ethanol (corn stover) Anaerobic Digestion to acetic acid (corn stover) Methanol – Bonivardi, et al., 1998 Methanol – Jun, et al., 1998 Methanol – Ushikoshi, et al., 1998 Methanol – Nerlov and Chorkendorff, 1999 Methylamines (MMA and DMA) Ethanol Dimethyl ether Hydrogen/synthesis gas Acetic acid – new process Styrene - new method Electric furnace process for phosphoric acid Haifa process for phosphoric acid SO2 recovery from gypsum waste S and SO2 recovery from gypsum waste Comparison of Base Case with Optimal Structure (Triple Bottomline) Base Case Million $/year 2,026 Optimal Structure Million $/year 2,490 Economic Costs 697 516 Raw Material Costs 685 470 12 46 Environmental Costs 457 313 Sustainable Credits(+)/Costs(-) -18 -10 Triple Bottomline 854 1,650 Income from Sales Utility Costs Comparison of Base Case with Optimal Structure (Energy Requirement) Base Case (TJ/yr) Optimal Structure (TJ/yr) Ammonia 3,820 3,820 Methanol 2,165 1,083 -14,642 -14,642 5,181 5,181 Corn Ethanol na 4,158 Fatty Acid Methyl Esters na 1,293 4,374 5,512 898 6,405 Sulfuric acid Wet process phosphoric acid Others Total Energy Comparison of CO2 use in Base Case and Optimal Structure Base Case Emission (million metric tons per year) : 0.75-0.14 = 0.61 Optimal Structure Emission (million metric tons per year) : 1.07-1.07 = 0 Pure Carbon Dioxide Consumption 1.2 1.2 1 1 0.32 0.8 0.6 1.07 0.4 0.75 0.75 million metric tons per year million metric tons per year Pure Carbon Dioxide Sources 0.16 0.8 0.6 1.07 0.4 0.2 0.2 0 0 0.14 Base Case Optimal Structure Pure CO2 (ammonia plant) Pure CO2 (bioprocesses) 0.84 Base Case 0.07 Optimal Structure Pure CO2 (new CO2 chemicals) Pure CO2 (algae) Pure CO2 (existing chemical plants) Multicriteria Optimization Problem Maximize: w1P+w2S P = Product Sales – Economic Costs – Environmental Costs S = Sustainability (Credits – Costs) w1 + w 2 = 1 Subject to: Multiplant material and energy balance Product demand Raw material availability Plant capacities Pareto Optimal Solutions Sustainable Credit(+)/Cost(-) (million dollars per year) 30 25 20 15 10 P=$1,194 M/yr S=$26 M/yr w1: 0.000-0.003 P=$1,346 M/yr S=$25.6 M/yr w1: 0.004-0.035 P=$1,369 M/yr S=$24.7 M/yr w1: 0.036-0.106 P=$1,660 M/yr S=-$ 9.98 M/yr w1: 0.107-1.000 5 0 -5 -10 -15 1100 1200 1300 1400 1500 Profit (million dollars per year) 1600 1700 Sensitivity of Optimal Solution Cumulative Probability of Triple Bottomline 100% Cumulative Probability (%) 90% 80% $2,150 million/yr 70% 60% 50% 40% 30% 20% 10% 80% $1,650 million/yr 20% 0% Triple Bottomline (million dollars per year) 20% probability of Triple Bottomline equal or below $1,650 million per year 80% probability of Triple Bottomline equal or below $2,150 million per year Case Studies with Superstructure Case Study Case Study I – Superstructure without carbon dioxide use Case Study II – Effect of sustainable costs and credits on the triple bottomline Case Study III – Effect of algae oil production costs on the triple bottomline Case Study IV – Multicriteria optimization using 30% oil content algae production and sustainable costs/credits Case Study V – Effect of corn and corn stover costs and number of corn ethanol plants on the triple bottomline Result Triple bottomline decreased to $984 million per year in optimal structure without CO2 use from $1,650 million per year in optimal structure with CO2 use. The highest triple bottomline was $1,700 million per year for CO2 cost of $5 and credit of $50 per MT/ton and the lowest was $1,652 million per year for CO2 cost of $125 and credit of $25 per MT/ton. Comparative study of algae oil production costs based on strain (30% or 50% oil content) and technology (HP,LP,AP). High performance plant for 30% and high and average performance plant for 50% oil content strain were included in optimal solutions. Algae production costs comparable to soybean oil purchased price were included in optimal structure. 30% oil content high performance and low performance algae oil production with $125/MT CO2 cost and $25/MT CO2 credit. Pareto optimal sets obtained for multicriteria of maximizing profit and sustainable credits. Corn stover is competitive when corn price is high. Constraints on corn ethanol plants showed that decreasing the number of corn ethanol plants decreased the triple bottomline, as corn stover ethanol plants used more energy and emitted impure CO2. Summary • Extend the Chemical Production Complex in the Lower Mississippi River Corridor to include: Biomass feedstock based chemical production CO2 utilization from the complex • Obtained the process designs and constraints • Assigned Triple Bottomline costs: Economic costs Environmental costs Sustainable credits and costs • Solved Mixed Integer Non Linear Programming Problem with Global Optimization Solvers to obtain optimal solution (including Pareto optimal sets) • Uses Monte Carlo Analysis to determine sensitivity of the optimal solution Conclusions • Demonstrated a new methodology for the integration of bioprocesses in an existing industrial complex producing chemicals. – Five processes designed in Aspen HYSYS® and cost estimations performed in Aspen ICARUS®. – Three processes converted biomass to chemicals, and two processes converted the bioproducts into ethylene and propylene chain chemicals. – Fourteen bioprocess blocks were integrated into a base case of plants in the Lower Mississippi River corridor to form a superstructure. • Optimal configuration was determined by optimizing a triple bottom line profit equation. – Renewable resources as feedstock and carbon dioxide utilization had the triple bottomline profit increase by 93% from the base case. – Algae oil production and other chemical processes consumed all the pure carbon dioxide emitted from the complex. – Sustainable costs to the society decreased by 44% due to complete consumption of pure CO2. – Total energy required by the optimal complex was 6,405 TJ/yr. – Total utility costs for the complex increased to $46 million per year from $12 million per year in the base case. Conclusions • Multicriteria optimization of the complex gave Pareto optimal solutions . A range of profit and sustainable credits/costs was obtained for a range of weights on the multiple objectives. • Monte Carlo simulations of the complex gave sensitivity of triple bottomline with respect to price of raw materials and products. • Five case studies demonstrated the use of chemical complex optimization for sustainability analysis. • The methodology could be applied to other chemical complexes in the world for reduced emissions and energy savings. Recommendations • The methodology can be applied to other chemical complexes of the world. Plants in the Gulf Coast Region (Texas, Louisiana, Mississippi, Alabama) could be included in the base case. • Raw material availability constraints related to crop cycles and transportation costs can be included in the model (supply-chain). • Price elasticities can be used as leading indicators to estimate future prices of chemicals in the complex and have optimization over time periods. • HYSYS designs for algae oil production and gasification processes can be made when more data becomes available for these processes. Acknowledgements • Dr. R. Pike, Dr. F.C. Knopf, Dr. J. Romagnoli, Dr. K.T. Valsaraj and Dr. J. Dowling • The Cain Department of Chemical Engineering, LSU for support • Tom Hertwig for industrial expertise • Lise Laurin (Earthshift) for Total Cost Assessment Methodology • Aimin Xu and Sudheer Indala for the base case