GENERAL DILUTION VENTILATION

advertisement

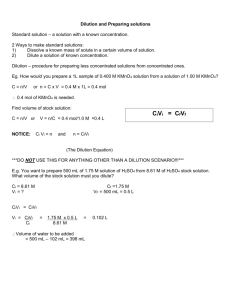

General Dilution Ventilation General Dilution Ventilation The supply and exhaust of air in a building Types of general dilution ventilation: Type1: dilution ventilation (D.V.) D.V. Is the dilution of contaminated air with uncontaminated air for controlling potential airborne health hazards, fire and explosive conditions, odors and nuisance type contaminants D.V. Also includes the control of airborne contaminants such as vapors, gases and particulates generated within tight buildings D.V. Is not as satisfactory for health hazard control as is local exhaust ventilation Type 2 : heat control ventilation It is the control of indoor atmospheric conditions found in hot industrial environments. The purpose is to prevent discomfort or injury to workers General Dilution Ventilation 2 Dilution Ventilation for Health Dilution ventilation is generally used to control the vapors from organic liquids with a TLV of 100 ppm or higher. The limiting factors for D.V. For health are: The quantity of contaminant generated must not be too great or the air flow rate necessary for dilution will be impractical. Workers must be at an appropriate distance from the contaminant source or the exposed contaminant must be in sufficiently low concentrations so that workers will not have an exposure in excess of the established TLV. The toxicity of the contaminant must be low. The emission rate of contaminants must be reasonably uniform. General Dilution Ventilation 3 Parameters Required for Determination of Dilution Ventilation Rates Solvent vapor per minute (i.E. Evaporation rate ) Specific gravity of liquid Molecular weight Acceptable health standard (threshold limit value i.E. TLV) K factor for incomplete mixing General Dilution Ventilation 4 General Dilution Ventilation Equation Rate of accumulation = Rate of generation – Rate of removal Vdc = Gdt – Q’Cdt Where V = Volume of room G = Rate of generation Q’ = Effective volumetric flow rate C = Concentration of gas or vapor in ppm t = time For steady state condition, change in concentration, dC = 0 Gdt = Q’Cdt For constant concentration C and uniform generation rate G, the above equation may be integrated as Q’ = G/C Now, G = (403 * SG * ER)/MW General Dilution Ventilation 5 General Dilution Ventilation Equation Q’ = (403 * 106 * SG * ER)/MW * C Where SG = Specific gravity ER = Emission rate in pints/minute MW = molecular weight G = Rate of generation in cfm C = Concentration of gas or vapor in ppm Actual Ventilation Rate Q = Q’ * K Where K = factor for incomplete mixing and lies between 1 and 10 and depends on: Efficiency of mixing Toxicity of chemicals Duration of the process General Dilution Ventilation 6 Contaminant Concentration Build Up Vdc = Gdt - Q’Cdt Rearranging the terms and integrating from time t1to t2 and concentration C1to C2 , we get ln[(G-Q’C2 )/ [(G-Q’C1 ) = -Q’/V(t2-t1) Δt = t2 - t1 Δt = -V/Q’ * ln [(G-Q’C2 )/ [(G-Q’C1 ) If initial concentration C1 = 0 and Q’ = Q/K then Δt = K(V/Q)ln [G )/ [G-((Q/K)C2 )] Note: C is in parts /106 General Dilution Ventilation 7 Rate of Purging For this case, rate of contaminant generation G = 0 VdC = -Q’Cdt dC/ C = (-Q’/V)dt Integrating from time t1to t2 and concentration C1to C2 , we get ln(C2 / C1) = -Q’/V(t2-t1) t2 - t1 = -(V/Q’) ln(C2 / C1) If initial time t1=0 then t2 = -(V/Q’) ln(C2 / C1) = -(V/Q’) ln(C1 / C2) Q’= Q/K t2 = K(V/Q) ln(C1 / C2) Where t2=time, minutes General Dilution Ventilation 8 Mixtures-dilution Ventilation for Health When two or more hazardous substances are present, then their combined effect known as the additive effect should be given primary consideration If (C1/TLV1) + (C2/TLV2) +……… (Cn/TLVn) > 1 then the threshold limit of the mixture is considered to be exceeded Where C = observed atmospheric concentration TLV = corresponding threshold limit General Dilution Ventilation 9 Ventilation for Heat Control History of heat stress Steel industry Glass industry Mining industry Paper industry Heat load on a person Metabolism Conduction Convection Radiation Evaporation General Dilution Ventilation 10 Heat Balance and Exchange delta s = (M – W) + C + R - E delta s = change in body heat content (M-W) = total metabolism C = convection heat exchange R = radiative heat exchange E =evaporative heat loss C and R are positive if delta s increases in heat Data required: Measurement of metabolic heat production Air temperature Air water vapor pressure Wind velocity Mean radiant temperature General Dilution Ventilation 11 Methods of Heat Exchange Convection Radiation Evaporation Convection C = 0.65Va0.6 (ta-tsk) Where C = convective heat exchange, Btu/h Va = air velocity, fpm ta = air temperature, F tsk = mean weighted skin temperature, usually assumed to be 95 F General Dilution Ventilation 12 Methods of Heat Exchange Radiation R = 15.0 (tw - tsk) Where: R = radiant heat exchange , Btu/hr tw = mean radiant temperature,F tsk = mean weighted skin temperature(usually 95 F) General Dilution Ventilation 13 Methods of Heat Exchange Evaporation E = 2.4Va0.6(ρsk - ρa) Where: E = evaporative heat loss, Btu/h Va = air velocity, fpm ρa = water vapor pressure of ambient air,mm Hg ρsk= water vapor pressure on the skin, (assumed to be 42 mm Hg at a 95 F skin temperature) General Dilution Ventilation 14 Acute Heat Disorders 1. Heat stroke A major disruption of central nervous function Lack of sweating Rectal temperature > 410C Treatment Placing the patient in a shady area Removing the outer clothing Wetting the skin Increasing air movement Professional help General Dilution Ventilation 15 Acute Heat Disorders 2. Heat exhaustion Causes Lack of acclimatization Failure to consume sufficient water Symptoms Clammy, moist skin Weakness or extreme fatigue Giddiness Nausea Head ache Low weak pulse Treatment Resting in a cool environment where there is free flowing, dry air usually remediates the symptoms quickly. General Dilution Ventilation 16 Acute Heat Disorders 3. Heat cramps Characterized by spasms in skeletal muscles Occurs in people when body water and electrolyte levels have not been restored after extended periods of heavy sweating during exercise and/or heat stress Old Treatment Use more salt at meal times and provide 0.1% salt in drinking water Salt tablets can also be used Recommended Treatment Use of electrolytes (Mg, Ca, K) General Dilution Ventilation 17 Acute Heat Disorders 4. Heat rash It is an acute inflammatory skin disease Occurs commonly in areas of skin folds or where there is abrasive clothing Treatment The infected areas should be kept dry, unabated and open to free flowing, dry air General Dilution Ventilation 18 Heat Strain Measurement The severity of heat strain will vary greatly among people exposed to the same level of heat stress. Acute heat strain is indicated by: Visible sweating Discontinued sweating Elevated heart rate Elevated deep body temperature Decreased systemic arterial blood pressure Personal discomfort Infrequent urination General Dilution Ventilation 19 Heat Stress Measurement Dry-Bulb temperature Temperature as registered by a thermal sensor Natural Wet-Bulb temperature Temperature measured by a thermometer whose bulb is covered by a wetted wick and exposed to natural air movement unshielded from radiation Psychrometric Wet-Bulb temperature Temperature as registered by psychrometer Globe temperature It is the infrared radiant heat transfer measured by a temperature sensor at the center of a 6 inch hollow copper sphere which is painted both on the inside and outside General Dilution Ventilation 20 WBGT Index Indoors When radiant heat transfer is negligible WBGT = 0.7(Wet Natural Bulb Temperature) + 0.3(Globe Temperature) Outdoors When there is no source of radiant heat transfer WBGT = 0.7(Wet Natural Bulb Temperature) + 0.2(Globe Temperature) +0.1 (Dry Bulb Temperature) General Dilution Ventilation 21 Dilution Ventilation for Fire and Explosion It is necessary that the concentration of vapor in the work area should be below the lower explosive limit (LEL) (preferably<25% LEL). This is for fire and explosion only and not for health hazard Q = 403 * SG *100 *ER * SF/MW * LEL *B Where LEL SG ER SF MW B = lower explosive limit, parts per 100 = specific gravity = emission rate, pints/min = safety factor = molecular weight = constant ( 1 for temperatures up to 2500 F 0.7 for temperatures > 2500 F) General Dilution Ventilation 22