Shift to Industrialization

advertisement

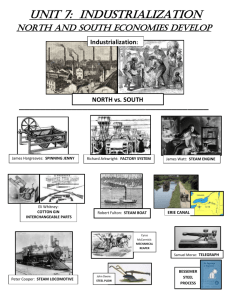

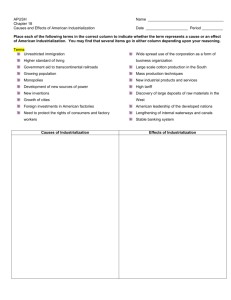

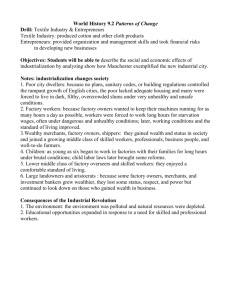

Shift to Industrialization INDUSTRIALIZATION In the early nineteenth century, the United States began a transition from a predominantly agricultural economy to an industrial one. hallharbor.com THE ECONOMIC FACTORS THAT BROUGHT ABOUT RAPID INDUSTRIALIZATION AND URBANIZATION WERE: 1) PLENTIFUL NATURAL RESOURCES 2) IMPROVED TRANSPORTATION 3) GROWING POPULATION 4) NEW INVENTIONS 5) INVESTMENT CAPITAL The shift from agriculture to industrialization caused an economic boom and made goods accessible to the masses. THE MAJOR EVENTS IN or CHARACTERISTICS OF THE ERA OF THE INDUSTRIAL REVOLUTION WERE: 1) the FACTORY SYSTEM 2) INVENTIONS 3) POPULATION SHIFT TO CITIES--URBANIZATION 4) IMMIGRATION 5) EXPANSION OF SLAVERY 6) REFORM MOVEMENTS INVENTIONS CHANGED INDUSTRIES AND SOCIETY COTTON GIN – made the cotton cleaning process more efficient MECHANICAL REAPER – cut ripe grain faster— increased farm productivity BESSEMER STEEL PROCESS – first inexpensive industrial process for the mass-production of steel. Decreased the cost, which… Increased steel production and work force But for many workers, especially skilled artisans, the new industrial economy led to a devaluation of their skills and loss of social status. For less-skilled workers industrialization often meant exploitation, long hours, and low pay. socl120.files.wordpress.com For others, the new manufacturing economy opened up opportunities for advancement. dipity.com The group of workers most dramatically affected by the onset of industrialization was artisans, or workers who used specialized skills to produce consumer goods, from shoes to bread to candles. sutcliffegalleries.com In the colonial period skilled artisans worked in small shops attached to their homes, using hand tools to produce goods for local consumption. yesteryearsnews.wordpress.com They also used an apprenticeship system, training boys in their skills in exchange for their labor. The relationship between artisan and apprentice was close. Typically an apprentice lived in his master’s house, receiving food, clothing, and education. plattsnisbett.com In the new factory system first pioneered by Samuel Slater in Rhode Island, the artisan system of small-scale production was replaced with a new set of roles: owners, managers, and wage workers. lotsofnoise.blogspot.com /industrialrevolutioninamerica.com The owner provided the money for the enterprise, the manager supervised the workers, and the laborers did the actual work, which was usually less skilled than the traditional crafts practiced by skilled artisans. red-grey.co.uk Some industries, such as textiles, shifted relatively rapidly to the use of power-driven machinery. In contrast, other industries like shoe production, did not and continued to employ many manual laborers into the 1860s. erih.net In both cases, the old craft traditions of artisans suffered because manufacturers could break down the production process into simple steps that could be performed by workers with minimal training. On the other hand, the production process made more goods available to more people and at cheaper prices! yougamble.blogspot.com CHANGES IN DAILY LIFE Factory work changed many aspects of daily life and culture. The work rhythm of artisans before the rise of the factory included periods of intense work activity followed by down time in which artisans might socialize with one another, perhaps meeting in a tavern to hang out and discuss politics. limerickwriter.wordpress.com Under industrialization the clock ruled. No more siestas! Factory workers were required to follow a strict schedule and perform at a steady pace day in and day out. www.uni.edu CHANGES IN THE WAY GOODS WERE MANUFACTURED With artisan production, skilled craftsmen produced items individually by hand. Each item was unique. It took time to make and was expensive. Also, if a part broke or was lost, the item had to be taken back to the person who made it so they could create the missing or broken part again by hand. That was a pain and also very expensive! CHANGES IN THE WAY GOODS WERE MANUFACTURED Factory goods were designed part by part to be identical—the parts interchangeable…INTERCHANGEABLE PARTS!!! Products could be produced FASTER, CHEAPER, in LARGE NUMBERS with less skilled, lower-waged workers which made them more affordable. The new system also led to a sharp separation between home and workplace. Before 1800, most artisans in New York had workshops attached to their homes, but by 1840, two-thirds of them lived in one place and worked in another. The factory system separated home and workplace... …and caused a major shift to urban areas—urbanization. www.wallpaperhere.com Relationship between urbanization and conflicts resulting from differences in religion, social class, and political beliefs: 1) Poverty 2) Discrimination towards immigrants, women, and children 3) Anti-immigration sentiment because immigrants willing to work for lower wages 4) Overcrowded apartment buildings 5) Crime 6) Disease 7) Fires 8) Know-Nothing Party (strict immigration policies) 9) Reform movements—women’s rights, child labor laws, etc. CHANGES IN MARKETING 1) Improvements in TRANSPORTATION allowed goods and people to move across the country much faster. This allowed the marketing and sale of goods to be much easier! CHANGES IN MARKETING 2) Because factory made goods cost less to produce, families of modest means could now afford items once available only to the wealthy. Ordinary Americans could now purchase furniture, clocks, dishes, silverware, and the latest fabrics. 3) Plus, if something broke, you could now go to the store and just buy a replacement part. www.xtimeline.com So…driven by new manufacturing technology and techniques, industrialization led to a vast increase in the number of goods – everything from clothing and shoes to tools and toys – available now and forever to the American consumer!!! Ushering in the modern CONSUMER CULTURE of America!!! deargirlwallflower.com