mas practice set

advertisement

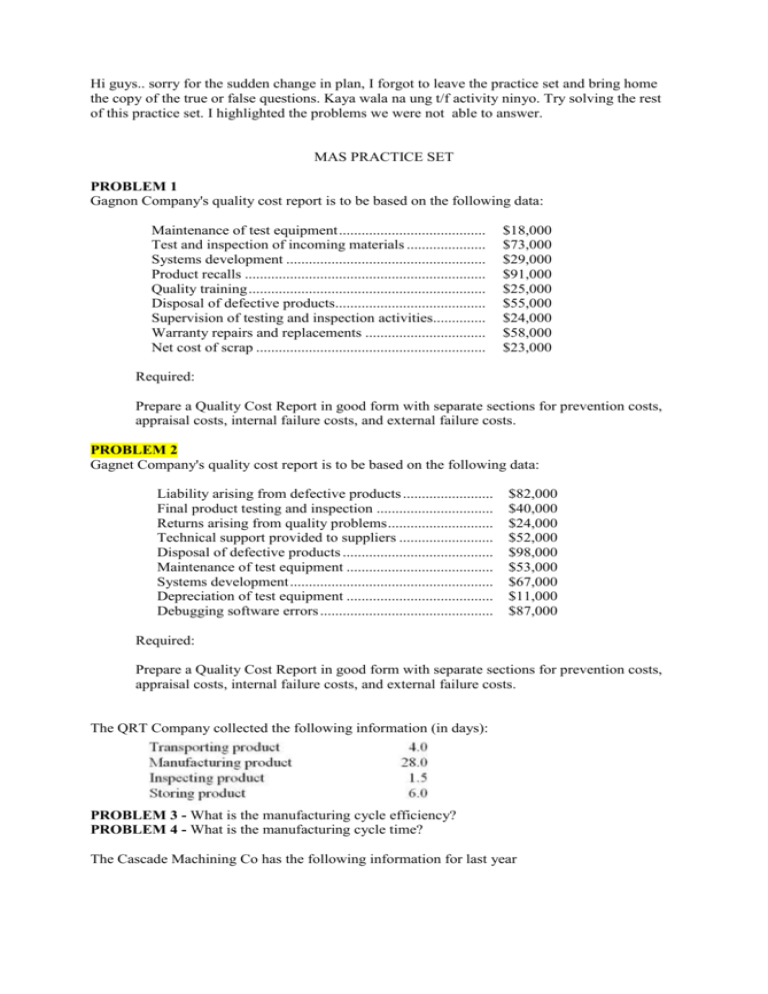

Hi guys.. sorry for the sudden change in plan, I forgot to leave the practice set and bring home the copy of the true or false questions. Kaya wala na ung t/f activity ninyo. Try solving the rest of this practice set. I highlighted the problems we were not able to answer. MAS PRACTICE SET PROBLEM 1 Gagnon Company's quality cost report is to be based on the following data: Maintenance of test equipment ....................................... Test and inspection of incoming materials ..................... Systems development ..................................................... Product recalls ................................................................ Quality training ............................................................... Disposal of defective products........................................ Supervision of testing and inspection activities.............. Warranty repairs and replacements ................................ Net cost of scrap ............................................................. $18,000 $73,000 $29,000 $91,000 $25,000 $55,000 $24,000 $58,000 $23,000 Required: Prepare a Quality Cost Report in good form with separate sections for prevention costs, appraisal costs, internal failure costs, and external failure costs. PROBLEM 2 Gagnet Company's quality cost report is to be based on the following data: Liability arising from defective products ........................ Final product testing and inspection ............................... Returns arising from quality problems ............................ Technical support provided to suppliers ......................... Disposal of defective products ........................................ Maintenance of test equipment ....................................... Systems development ...................................................... Depreciation of test equipment ....................................... Debugging software errors .............................................. $82,000 $40,000 $24,000 $52,000 $98,000 $53,000 $67,000 $11,000 $87,000 Required: Prepare a Quality Cost Report in good form with separate sections for prevention costs, appraisal costs, internal failure costs, and external failure costs. The QRT Company collected the following information (in days): PROBLEM 3 - What is the manufacturing cycle efficiency? PROBLEM 4 - What is the manufacturing cycle time? The Cascade Machining Co has the following information for last year PROBLEM 5 - The partial productivity for metal is ? PROBLEM 6 - The partial productivity for labor is ? PROBLEM 7 Toimi Toolworks Co. has provided the following information for last year: The total factor productivity measure is: PROBLEM 8 The ABC Manufacturing Company collected the following information (in days) for April and May. Required: a. Calculate the manufacturing cycle efficiency for April and May. b. Calculate the processing time required for May so that May's manufacturing cycle efficiency is equal to April's manufacturing cycle efficiency. PROBLEM 9 The XYZ Manufacturing Company collected the following information (in days) for July and August. Required: a. Calculate the manufacturing cycle efficiency for July and August. b. Assume September's processing time will be the same as August's. If XYZ's target for manufacturing cycle efficiency is 65%, what will September's target for manufacturing cycle time be? PROBLEM 10 Schroeder Forging Co. has provided the following information for last year: Required: Calculate the partial productivity for: a. Metal b. Labor PROBLEM 11 Schroeder Forging Co. has provided the following information for last year: Required: a. Calculate the total factor productivity measure. PROBLEM 1 Answer: Prevention costs Systems development ................................................... Quality training ............................................................ Total ................................................................................ Appraisal costs Test and inspection of incoming materials .................. Supervision of testing and inspection activities ........... Maintenance of test equipment .................................... Total ................................................................................ Internal failure costs Disposal of defective products ..................................... Net cost of scrap ........................................................... Total ................................................................................ External failure costs Warranty repairs and replacements .............................. Product recalls .............................................................. Total ................................................................................ Total quality cost ............................................................. PROBLEM 2 Answer: Prevention costs Technical support provided to suppliers ...... Systems development ................................... Total ................................................................ Appraisal costs Depreciation of test equipment .................... Maintenance of test equipment .................... Final product testing and inspection ............ Total ................................................................ Internal failure costs Debugging software errors ........................... $ 52,000 67,000 119,000 11,000 53,000 40,000 104,000 87,000 $ 29,000 25,000 54,000 73,000 24,000 18,000 115,000 55,000 23,000 78,000 58,000 91,000 149,000 $396,000 Disposal of defective products ..................... Total ................................................................ External failure costs Liability arising from defective products ..... Returns arising from quality problems ........ Total ................................................................ Total quality cost ............................................. 98,000 185,000 82,000 24,000 106,000 $514,000 PROBLEM 3 28.0/(4.0 + 28.0 + 1.5 + 6.0) = 28.0/39.5 = 70.9% PROBLEM 4 4.0 + 28.0 + 1.5 + 6.0 = 39.5 days PROBLEM 5 6,000/150,000 = 0.040 PROBLEM 6 6,000/12,000 = 0.500 PROBLEM 7 Value of output: 16,000 $75 = $1,200,000; Value of input: (20,000 $15) + (15,000 $30) + $225,000 = $975,000; $1,200,000/$975,000 = 1.231 PROBLEM 8 a. April: 57.1%; May: 64.5% b. 11.7 days Feedback: a. April: [14.0/(2.0 + 14.0 + .5 + 8.0)] = 57.1% May: [16.0/(3.0 + 16.0 + .8 + 5.0)] = 64.5% b. [x/(3.0 + + .8 + 5.0)] = .57143; = 11.7 PROBLEM 9 a. July: 64.2%; August: 61.6% b. 27.69 days Feedback: a. July: [17.0/(2.0 + 17.0 + .5 + 7.0)] = 64.2% August: [18.0/(3.0 + 18.0 + 1.2 + 7.0)] = 61.6% b. 18.0/x = .65; = 27.69 days PROBLEM 10 a. .714 b. 2 tons/hr Feedback: a. 10,000 tons output/14,000 tons input = .714 b. 10,000 tons/5,000 hours = 2 tons/hr PROBLEM 11 a. 1.446 Feedback: Value of output: 10,000 $60 = $600,000; Value of input: (14,000 $10) + (5,000 $30) + $125,000 = $415,000; $600,000/$415,000 = 1.446