Cost of Quality? - UMT Admin Panel

advertisement

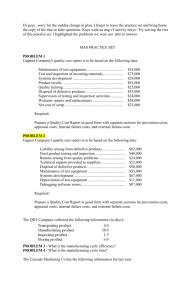

Introduction to a Quality Tool Ijaz yusuf (Pakistan) Cost of Quality? Cost of Quality (COQ), Price of Non Conformance (PONC), Cost of Poor Quality (COPQ), Quality Costing (QC) and Quality Cost Analysis (QCA) are the few names attached to this well known toll as Juran said in 1951 “ Gold is the mine. Cost of quality is the gold which is available in the form of failure costs only mining is required in the form of long term investment since failure costs usually constitutes 65-70% of company’s quality costs, appraisal is normally 20-25% and prevention is 5%. The term “Quality Costs” is associated solely with defective products, a) The cost of making defective products b) The cost of finding defective products c) The cost of repairing defective products d) The cost of avoiding defective products Cost of Quality is usually sum of costs incurred to prevent nonconformances in products and systems. In the post- WTO scenario, where the cut-throat competition prevails, market determines the price, customer pressurize for price reductions and shrinking profit seems the only choice. Cost of Quality is the sole hope that can avert the situation if it is implemented effectively. Cost of Quality varies company to company but if it is quantified properly, it will immediately get the attention at all management levels. Why? When added together, the cost of poor quality makes up as much as 10% to 30% of all costs. High COPQ draws the management attention to adopt certain measures. High COQ acts as a change agent that certain fundamental changes in products and services are required to reduce these high costs. COPQ helps a lot to improve an organization’s financial condition and set the organization on the track of improvement. If we chop off the tip of ice burg of cost of poor quality the most obvious costs are customer returns, waste, rejects, rework, testing costs, product recalls, inspection costs, yield losses and most hidden costs are customer allowances, planning delays, high time over. Overdrew receivables, pricing or billing errors, partially completed sales orders, freight charges, complaint handling costs, excessive field service costs, excessive employee turnover, warranty claims etc. prevent or reduce the risk of nonconformity or defect. These costs of poor quality appear due to poor performance and could disappear entirely if every activity performed without deficiency every time. Major categories of Quality Costs are Prevention Costs, Appraisal Costs, Internal Failure Costs and External Failure Costs representing the elements of PAF model. Step 2: Decide how to estimate the costs. Prevention Costs These are the cost of any action taken to investigate, The costs of quality is usually interpreted in financial terms and Appraisal Costs These are the costs of evaluating the achievement of quality requirement including the cost of verification and control performed at any stage of Quality Loop. Internal Failure Costs These are costs arising within the organization if defects exist in the product prior to shipment to customer. External Failure Costs These are costs resulting from failing to conform to specified requirements after the delivery. Five Steps to Measure Cost of Quality Step 1: Identify the element of Costs of Quality. Step 3: Collect data and estimate costs. Step 4: Analyze results and diagnose the reasons. Step 5: Highlight the areas of improvement. translated in money form (language of management). Followings are the ways to interpret; percentage of sales turnover, percentage of profit margins, and percentage of all costs in industries. About Author Ijaz Yusuf is working as a Manager Productivity Improvement at Packages Ltd. Lahore and he is the Technical Editor of Magazine of Quality and Productivity Society of Pakistan. He can be contacted at: ijaz_y@hotmail.com