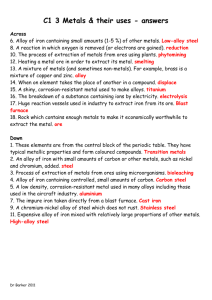

alloy - Classes

advertisement

IE 337: Materials & Manufacturing Processes Lecture 3: Metal Alloys and Heat Treatment Chapters 3, 6 and 27 Last Time The nature of metals Different crystalline structures Different crystalline defects that affect properties The properties of metals Mechanical properties What they are and what they mean 2 Stress-Strain Relationships Figure 3.3 Typical engineering stress-strain plot in a tensile test of a metal. 3 True Stress-Strain Curve Figure 3.4 - True stress-strain curve for the previous engineering stress-strain plot in Figure 3.3. 4 This Time 5 Hardness (Chapter 3) How can we modify mechanical properties in metals? (Chapter 6 and 27) Different types of metal alloys and how are they used (Chapter 6) Assignment #1 Hardness Resistance to permanent indentation Good hardness generally means material is resistant to scratching and wear Most tooling used in manufacturing must be hard for scratch and wear resistance 6 Brinell Hardness Test Widely used for testing metals and nonmetals of low to medium hardness A hard ball is pressed into specimen surface with a load of 500, 1500, or 3000 kg Figure 3.14 Hardness testing methods: (a) Brinell 7 Brinell Hardness Number Load divided into indentation area = Brinell Hardness Number (BHN) HB 2F Db (Db Db2 Di2 ) where HB = Brinell Hardness Number (BHN), F = indentation load, kg; Db = diameter of ball, mm, and Di = diameter of indentation, mm 8 Rockwell Hardness Test Figure 3.14 Hardness testing methods: (b) Rockwell: (1) initial minor load and (2) major load. 9 Why Metals Are Important High stiffness and strength - can be alloyed for high rigidity, strength, and hardness Toughness - capacity to absorb energy better than other classes of materials Good electrical conductivity - Metals are conductors Good thermal conductivity - conduct heat better than ceramics or polymers Cost – the price of steel is very competitive with other engineering materials 10 Metals: Periodic Table 26 Fe 55.847 11 Starting Forms of Metals used in Manufacturing Processes Cast metal - starting form is a casting Wrought metal - the metal has been worked or can be worked after casting Powdered metal - starting form is very small powders for conversion into parts using powder metallurgy techniques 12 Classification of Metals Ferrous - those based on iron Steels Cast irons Nonferrous - all other metals Aluminum, magnesium, copper, nickel, titanium, zinc, lead, tin, molybdenum, tungsten, gold, silver, platinum, and others Superalloys 13 Metals and Alloys Some metals are important as pure elements (e.g., gold, silver, copper) Most engineering applications require the enhanced properties obtained by alloying Through alloying, it is possible to increase strength, hardness, and other properties compared to pure metals 14 Alloys An alloy = a mixture or compound of two or more elements, at least one of which is metallic Two main categories: 1. Solid solutions Substitutional Interstitial 2. Intermediate phases 15 Two Forms of Solid Solutions Figure 6.1 Two forms of solid solutions: (a) substitutional solid solution, and (b) interstitial solid solution. 16 Equilibrium Binary Phase Diagram Figure 6.2 Phase diagram for the copper-nickel alloy system. 17 Intermediate Phases There are usually limits to the solubility of one element in another When the amount of the dissolving element in the alloy exceeds the solid solubility limit of the base metal, a second phase forms in the alloy The term intermediate phase is used to describe it because its chemical composition is intermediate between two phases Its crystalline structure is also different from those of the pure metals 18 Tin-Lead Phase Diagram Figure 6.3 Phase diagram for the tin-lead alloy system. 19 Melting in the Tin-Lead Alloy System 20 Pure tin melts at 232C (449F) Pure lead melts at 327C (621F) Tin-lead alloys melt at lower temperatures The diagram shows two liquidus lines that begin at the melting points of the pure metals and meet at a composition of 61.9% Sn This is the eutectic composition for the tin-lead system Eutectic Alloy A particular composition in an alloy system for which the solidus and liquidus are at the same temperature The eutectic temperature = melting point of the eutectic composition The eutectic temperature is always the lowest melting point for an alloy system The word eutectic is derived from the Greek word eutektos, meaning easily melted 21 Metals: Classification FERROUS 22 IMPORTANCE OF IRON 23 Steel: engineered alloys based on iron (often containing carbon): 10,000 compositions in common use One of mankind’s most popular engineering materials: 750 million tons per year Fe melting temp. = 1537°C Fe density = 7.87 g/cm3 Iron-Carbon Phase Diagram Figure 6.4 Phase diagram for iron-carbon system, up to about 6% carbon. 24 The Several Phases of Iron The phase at room temperature is alpha (), called ferrite (BCC) At 912C (1674F), ferrite transforms to gamma (), called austenite (FCC) This transforms at 1394C (2541F) to delta () (BCC) Pure iron melts at 1539C (2802F) 25 Solubility Limits of Carbon in Iron Ferrite phase can dissolve only about 0.022% carbon at 723C (1333F) Austenite can dissolve up to about 2.1% carbon at 1130C (2066F) The difference in solubility between alpha and gamma provides opportunities for strengthening by heat treatment 26 Steel and Cast Iron Defined Steel = an iron-carbon alloy containing from 0.02% to 2.1% carbon Cast iron = an iron-carbon alloy containing from 2.1% to about 4% or 5% carbon Steels and cast irons can also contain other alloying elements besides carbon 27 Fe-C: Properties 28 Annealing Heating and soaking metal at suitable temperature for a certain time, and slowly cooling Reasons for annealing: Reduce hardness and brittleness Alter microstructure to obtain desirable mechanical properties Soften metals to improve machinability or formability Recrystallize cold worked metals Relieve residual stresses induced by shaping 29 Annealing of Steel Full annealing - heating and soaking the alloy in the austenite region, followed by slow cooling to produce coarse pearlite Usually associated with low and medium carbon steels Normalizing - similar heating and soaking cycle as in full annealing, but faster cooling rates, Results in fine pearlite, higher strength and hardness, but lower ductility 30 Time-Temperature-Transformation Curve Allotropic transformation - austenite to martensite Figure 27.1 The TTT curve, showing transformation of austenite into other phases as function of time and temperature for a composition of about 0.80% C steel. Cooling trajectory shown yields martensite. 31 Tempering of Martensite A heat treatment applied to martensite to reduce brittleness, increase toughness, and relieve stresses Treatment involves heating and soaking at a temperature below the eutectoid for about one hour, followed by slow cooling Results in precipitation of very fine carbide particles from the martensite iron-carbon solution, gradually transforming the crystal structure from BCT to BCC New structure is called tempered martensite 32 Steels 33 Alloy Steels 34 Further refined from carbon steels, with elements added to modify or change the mechanical properties. Alloy Steels Further refined from carbon steels, with elements added to modify or change the mechanical properties. Tool Steels are special grades of alloy steels used for a variety of tooling, with very close control of the alloying element additions Highly wear-resistant Highly shock-resistant Heat-resistant 35 Alloy Steels 36 Cr addition improves corrosion resistance So does Ni Alloy Steels: Alloying Elements Boron Increases wear-resistance Increases hot-hardness ability to keep shape at elevated temperature Used in high speed steel Large increase in hardenability with very small addition of element Chromium Increases depth hardness Increases corrosion resistance Principle component in stainless steel 37 Cobalt Lead Reduces cutting friction, improving machinability Good weldability Good formability Environmental concern Alloy Steels: Alloying Elements Manganese Large amounts (1% 15%) gives good hardness and wearresistance Small amounts useful for purifying melt by combining with impurities and forming dross Vanadium Also used to purify melt Produces fine-grained steels 38 Tungsten Provides high wearresistance Adds hardenability and strength at elevated temperatures Used in tool steels Phosphorous / Sulfur Give excellent machining characteristics Used in free-machining steels Alloy Steels: Alloying Elements Molybdenum 39 Aids toughness Used in tool steels Improves depth-hardness Improves strength at elevated temperatures Nickel Provides corrosionresistance Improves resistance to elevated temperatures Used in stainless steels Combined with Molybdenum to provide very tough steel for aircraft applications General Cast Iron Properties Advantages: Very good compressive strength Good machinability Reasonable corrosion resistance Disadvantages: Natural brittleness 40 Cast Iron: 2-4.5 wt. % C Gray Iron 1-3 % Si cheap used in compression vibrational damping (machinery housing) White Iron < 1% Si brittle, wear resistant malleable iron precursor (rollers) 41 Ductile Iron Mg, Ce, Ca, Li, Na, Ba to gray iron stronger and ductile (valves, gears, crankshafts) Malleable Iron < 1% Si heat treat white iron strong, malleable (connecting rods, transmission gears flanges, fittings) Non-Ferrous Metals Metals whose major element is not Iron (wow!) Compared to Iron & Steel: Density (strength to weight ratio), non-corrosive Conductivity, fabricatability (machined, formed, cast) Cost (by weight) 42 Major Materials: Aluminum Alloys Copper & Copper Alloys Magnesium Nickel & Nickel Alloys Refractories Superalloys Non-Ferrous Alloys • Cu Alloys • Al Alloys Brass: Zn is subst. impurity -lower r: 2.7g/cm3 (costume jewelry, coins, -Cu, Mg, Si, Mn, Zn additions corrosion resistant) -solid sol. or precip. Bronze: Sn, Al, Si, Ni are strengthened (struct. subst. impurity aircraft parts (bushings, landing & packaging) gear) • Mg Alloys NonFerrous Cu-Be: -very low r: 1.7g/cm3 Alloys precip. hardened -ignites easily for strength -aircraft, missles • Ti Alloys • Refractory metals -lower r: 4.5g/cm3 -high melting T vs 7.9 for steel • Noble metals -Nb, Mo, W, Ta -reactive at high T -Ag, Au, Pt -oxid./corr. resistant -space applic. 43 Aluminum Alloys Pure metal properties: Alloying elements: 44 Low density, melting point Ductile Malleable Good electrical / thermal conductor Copper Magnesium Silicon Manganese Zinc Typical uses of Al: High strength aircraft structures Low pressure hydraulic/pneumatic fittings Jet engine parts Truck frames Precipitation Hardening Heat treatment that precipitates fine particles that block the movement of dislocations and thus strengthen and harden the metal Principal heat treatment for strengthening alloys of aluminum, copper, magnesium, nickel, and other nonferrous metals Also utilized to strengthen a number of steel alloys that cannot form martensite by the usual heat treatment 45 Conditions for Precipitation Hardening The necessary condition for whether an alloy system can be strengthened by precipitation hardening is the presence of sloping solvus line in the phase diagram A composition in this system that can be precipitation hardened is one that contains two equilibrium phases at room temperature, but which can be heated to a temperature that dissolves the second phase 46 Precipitation Hardening Figure 27.5 Precipitation hardening: (a) phase diagram of an alloy system consisting of metals A and B that can be precipitation hardened; and (b) heat treatment: (1) solution treatment, (2) quenching, and (3) precipitation treatment. 47 Sequence in Precipitation Hardening 1. Solution treatment - alloy is heated to a temperature Ts above the solvus line into the alpha phase region and held for a period sufficient to dissolve the beta phase 2. Quenching - to room temperature to create a supersaturated solid solution 3. Precipitation treatment - alloy is heated to a temperature Tp, below Ts, to cause precipitation of fine particles of the beta phase 48 Copper Alloys Pure metal properties: Very soft Ductile Malleable Good electrical / thermal conductor Typical uses of Cu: Electronics production Electrical conductors Typical uses as Bronze: Alloying elements: Alloyed with Sn to make Bronze Alloyed with Zn to make Brass 49 Machine parts Bearings Corrosion-resistant fittings Electrical connectors Typical uses as Brass: Hardware Marine corrosionresistance Ornamental applications Magnesium Alloys Pure metal properties: Aircraft components (strength to weight ratio) Automobile wheels Racing frames Lightweight structural parts Lightweight Strong (per unit volume) Flammable in fine sizes Alloying elements: 50 Aluminum Bismuth Copper Tin Lead Iron Typical uses of Mg: Handling Magnesium Keep chips coarse Avoid chip accumulation, mixing with other material Avoid water, water-based coolants (explosive) Nickel Alloys Properties: Corrosion resistance Heat resistance Alloy forms: 51 Monel K-Monel R-Monel Inconel Typical uses of Ni: Plating of electronics (pure form) Thermocouples Alloying element Naval Brass Steel toughness Steel corrosion resistance Steel heat resistance Effect of Temperature on Properties Figure 3.15 General effect of temperature on strength and ductility. 52 Hot Hardness Ability of a material to retain hardness at elevated temperatures Figure 3.16 Hot hardness - typical hardness as a function of temperature for several materials. 53 Superalloys High-performance alloys for strength and resistance to surface degradation at high service temperatures Many superalloys contain substantial amounts of three or more metals, Commercially important because they are very expensive See Tables 6.15 & 6.16 54 Why Superalloys are Important 55 High temperature performance is excellent tensile strength, hot hardness, creep resistance, and corrosion resistance at very elevated temperatures Operating temperatures often in the vicinity of 1100C (2000F) Applications: gas turbines - jet and rocket engines, steam turbines, and nuclear power plants - systems in which operating efficiency increases with higher temperatures Refractory Metals Metals capable of enduring high temperatures - maintaining high strength and hardness at elevated temperatures Most important refractory metals: Molybdenum Tungsten 56 Other refractory metals are niobium and tantalum (used in capacitors) Tungsten 57 Properties: highest melting point among metals, one of the densest, also the stiffest (highest modulus of elasticity) and hardest of all pure metals Applications typically characterized by high operating temperatures: filament wire in incandescent light bulbs, parts for rocket and jet engines, and electrodes for arc welding Also widely used as an element in tool steels, heat resistant alloys, and tungsten carbide Molybdenum 58 Properties: high melting point, stiff, strong, good high temperature strength Used as a pure metal (99.9+% Mo) and alloyed Applications: heat shields, heating elements, electrodes for resistance welding, dies for high temperature work (e.g., die casting molds), and parts for rocket and jet engines Also widely used as an alloying ingredient in steels and superalloys Precious Metals Gold, platinum, and silver Also called noble metals because chemically inert Available in limited supply 59 Widely used in jewelry and similar applications that exploit their high value Properties: high density, good ductility, high electrical conductivity and corrosion resistance, and moderate melting temperatures Shaping, Assembly, and Finishing Processes for Metals 60 Metals are shaped by all of the basic processes: casting, powder metallurgy, deformation, and material removal In addition, metal parts are joined to form assemblies by welding, brazing and soldering, and mechanical fastening Heat treating to enhance properties Finishing processes (e.g., electroplating and painting) to improve appearance and/or to provide corrosion protection You should have learned: How we can modify mechanical properties in metals? 61 Alloying Annealing Allotropic transformation Precipitation hardening Different types of metal alloys and how they are used? Assignment #1 Next Time How do we shape materials? Secondary operations Material Removal The fundamentals of metal cutting (Chapter 21) Orthogonal machining The Merchant Equation 62