MATS112

advertisement

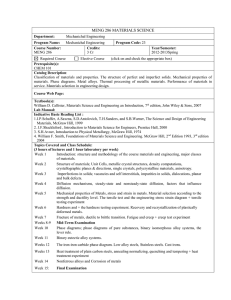

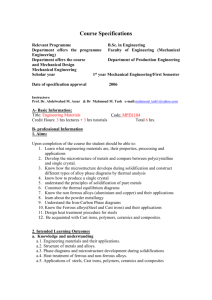

2002/03 MODULE SPECIFICATION Module Code: MATS112 Faculty of Engineering, University of Liverpool Department of Engineering: Materials Science and Engineering Module title: Mechanical Properties and Microstructure of Metals CATS level: 1 CATS value: 7.5 Staff (with email addresses) Co-ordinator: Dr TJ Bullough (timbull@…) Moderator: Lecturer(s): Dr TJ Bullough Lectures: 18 Seminars/tutorials: 3 Study hours Other: Pre-requisites: Co-requisites: None None Availability to (student groups/years): Compulsory/core: MECH1, AERO1, INTENG1, MATS1 Semester: 1 Dr YY Zhao (y.y.zhao@) Labs: Private study: 6 27 Modules for which this module is a pre-requisite: MATS210, MATS214, MATS213, MATS222 Optional: - Learning and Teaching Strategies (eg, traditional lectures, supervised design classes) Lectures and laboratory work. Module Description Lecture/ Content Lab no. Lectures 1-2 The Tensile Test: elastic and plastic deformation, true stress and strain, work hardening. 3-4 Measures of Strength and Ductility. 5 The Hardness Test. Vickers, Brinell, Rockwell. 6 Brittle and Ductile Fracture: impact testing 7-8 Fatigue Failure and Fatigue Testing. 9-10 Creep: stress-rupture tests 11-13 Phase diagrams: Non-equilibrium cooling of alloys. Dendritic Growth. 14-16 Steels: composition, microstructure, heat treatment and properties. 17-18 Aluminium alloys: age hardening. Labs 1. 2. Structure and hardness of steels Heat treatment of plain carbon-steels Page 1 of 2 2002/03 MODULE SPECIFICATION Module Code: MATS112 Learning Outcomes: Knowledge and Understanding: On successful completion of the module, students should be able to demonstrate knowledge and understanding of: the principles of mechanical testing the British and European Standards for mechanical testing the link between microstructure and properties of metals the effects on microstructure and properties of heat treatments, especially for steels the use of phase diagrams. Intellectual Abilities: On successful completion of the module, students should be able to demonstrate ability in applying knowledge of the above topics to: the assessment of the mechanical properties of metals predict (using phase diagrams) microstructure, and microstructural evolution during heat treatment judge whether the mechanical properties of a metal make it appropriate for use describe and explain qualitative aspects of mechanical properties and microstructure. Practical Skills On completion of the module, students should be able to show experience and enhancement of the following discipline-specific practical skills: undertaking uniaxial tensile, Vickers Hardness, Charpy Impact and Jominy Tests using optical microscopes for microstructural examination. General Transferable Skills On completion of the module, students should be able to show experience and enhancement of the following key skills: number skills: recording and presenting data, and graph plotting technical reporting skills. Assessment Weighting % Formal exam: Class test(s)*: 80% 10% Laboratory(s)*: 10% Timing Duration/other Jan Midsemester See lab programme 2 hours; multiple-choice question format 1 hour; multiple-choice question format 2 x 3 hour * The University Lateness Penalty Scheme applies to all coursework September Resit opportunity: Yes Page 2 of 2 2002/03 MODULE SPECIFICATION Module Code: MATS112 Recommended reading: Essential text(s): WD Callister, Materials Science and Engineering: an introduction, J Wiley and Sons, ISBN 0471305685. Recommended text(s): There are many other materials science text books in the library which cover the topics in this module. The ASM (“American Society for Materials”) Handbook series, available in the library or networked CD-ROM (see below), provide extremely detailed information on all aspects of mechanical property testing and metals microstructures. Some useful or interesting Web/IT resources: http://www.matter.org.uk/ Online computer-based materials teaching resources – especially good for finding out about aluminium alloys and steel. The full suite of MATTER teaching software, which contains useful coverage of many relevant topics in materials science, is available on the University PC Win2000 managed network [Start>Network>Lecturers Applications>MATTER CD]. http://dbweb.liv.ac.uk/library_resources/cdroms.asp ASM Handbooks on University networked CD-ROMs. Volume 3 Alloy Phase Diagrams, Vol 9 Metallography and Microstructures. Extremely detailed information. http://www.npl.co.uk/npl/fth/guidance/hardness/index.html An overview of hardness measurement techniques http://www.matweb.com A materials-property database http://www.umist.ac.uk/material/microscope/zefold/zeus1e.htm An “Internet microscope” http://www.msm.cam.ac.uk/doitpoms/miclib/index.php A searchable collection of materials micrographs http://www.bsi-global.com The British Standards website. Also available via University electronic database. External Examiner responsible for module: Materials Science Version date: 14 August 2002 Page 3 of 2