Implementation 113010R10

advertisement

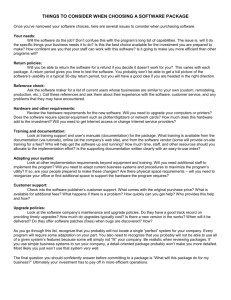

The Implementation Strategy Proposed SLAC Controls Upgrade December 1, 2010 Ray Larsen Outline 1. 2. 3. 4. 5. Existing System MTCA Module Development Single Station Upgrade Demo Plan Production & Test Plan Steps to Installation & Switchover (TH) 12-01-10 Controls Upgrade Implementation 2 Existing System • Every RF station has 2-bay rack for controls – 8 Stations per each of 30 Sectors – Includes 6-8 RF Stations for each injector – New upgrade RF plus accelerator controls can fit in single rack 12-01-10 Controls Upgrade Implementation 3 Klystron Gallery Layout Short cables top of penetration would need elongation to new rack KEEP OUT AREA FOR KLYSTRON REPLACEMENT 72" Penetration POSSIBLE NEW DOUBLE BAY RACK LOCATION Support Post Klystron 48" 14" 48" Fiat Racks 24" 48" 24" POSSIBLE NEW DOUBLE BAY RACK LOCATION 28" Possible Obstructions Sub-Booster (22") Arc Flash Boundary (12") Storage (6-42") Transformers (~36") Other Racks 12/01/10 12-01-10 Possible Obstructions: Keep Out Area PFN Tuning 28" Keep Out Area T20 Replacement (Can be shifted 6ft to the right) 40" Modulator Controls Upgrade Implementation Arc Flash Boundary Storage Transformers Other Racks 4 WG & Cable Penetration to Tunnel Existing Linac Klystron Station RF Control, Monitoring, and Interlocking System IPA Chassis Controls RF Phase and Amplitude PAD Chassis Measures RF Phase and Amplitude PIOP CAMAC Module Controls IPA, PAD, and MKSU. Interface to control system MKSU Chassis Interlock and Control for Klystron SLED Support Systems Existing Controls Racks New system will combine the PAD, IPA, and part of the PIOP into the RF Control System 12-01-10 Controls Controls Upgrade Upgrade Implementation Implementation 6 PIOPs (4) PDU Timing 12-01-10 Controls Upgrade Implementation 7 12-01-10 Controls Upgrade Implementation 8 Existing Rack Issue • Racks are sub-standard in meeting code, cooling and filtering protection – Ideally would install modern environmentally controlled closed racks – Not in budget & some stations lack space • Proposed work-around – Refurbish present rack to bring ~up to code, plus add power for local solenoid PS plan (new) – Insert secondary enclosure inside rack with crate cooling, sealed from dirty air, w/LCW air-water temp control 12-01-10 Controls Upgrade Implementation 9 2. MTCA Module Development • The following show the MTCA development strategy for in-house RTM design. • We are procuring generic COTS AMCs each of which will support a number of applications via RTMs 12-01-10 Controls Upgrade Implementation 10 MTCA Engineering Reference Design 4 DUAL DIFFERENTIAL SHLD’D PAIRS 12V PWR, GND, JTAG, IPMI HOT SWAP, PWR IPMI EJECTION LOGIC REAR I/O AMC 56 DUAL DIFFERENTIAL SHLD’D SIGNAL PAIRS IPMI MMC CONTROLLER FPGA DC-DC CONVERT HOT SWAP IPMI EJECTION LOGIC SERIAL Gb BACKPLANE RTM Double-wide plus RTM provides excellent analog space, ground noise control, crosstalk AMC space fully backward compatible with industry single-wide designs Reference Design complete w/ supporting FW-SW environment enables engineers to focus on payload design w/ power, IPMI basic infrastructure standardized 12/01/10 Controls Upgrade Implementation Adapting Controls Subsystems • Port existing front end interfaces onto RTMs • 4 & 10 Ch Fast ADCs w/DAC RTM adapters: 1. Stripline BPMs (2 types) 2. Toroids (2 types, Linac & Beam Containment), Profile Monitor Gated ADC (Same as above) 3. RF Feedback • 3-Industry Pack RTM Adapters: 4. 5. 6. 7. Profile Monitor Beam Length (BLEN) Vacuum gauge controller interface Vac-ion pump controller interface Wire scanner movers (Hytek) • PMC Card AMC Adapter 8. Fast Frame grabber for Profile Monitor Controls Upgrade Implementation Beamline BPMs, Toroids, Gated ADCs Strategy: AMC 1 FAST ADC 4 CH 16 BIT 119 MSPS (180 MSPS MAX) RTM 1 STRIPLINE BPM (2 TYPES) SIGNAL CONDITIONING, FILTERING & CALIBRATION RTM 2 TOROID (2 TYPES) SIGNAL CONDITIONING & CALIBRATION (Struck, Vadatech, Libera) RTM 2 GATED ADC SIGNAL CONDITIONING (GADC) 12/01/10 Controls Upgrade Implementation Encourage Industry to provide key generic complex AMC modules Develop 2 or more sources Encourage multiple labsupported specifications LLRF System, Feedback Apps 2856 MHZ REF IN AMC 2 FAST ADC 10 CH 16 BIT 119 MSPS 2 CH DAC 238 MSPS RTM-3 25 MHZ IF SIGNAL PASSTHROUGH DAC OUTPUT TO RF AMP I/O CNTRL IF SIGS DAC OUT (Struck, Vadatech Libera) 12/01/10 RTM-3 GENERIC FAST SIGNAL CONDITIONING UP TO 10 CH ANALOG IN, 2 CH DAC OUT Controls Upgrade Implementation RF FREQUENCY GENERATION LOCAL OSCILLATOR (LO) SAMPLING CLOCKS 8 CH DOWNCONVERTER Beamline Instruments via IP Adapter AMC 3 3-INDUSTRY PACK (IP) ADAPTER FOR PHYSICS BACKPLANE RTM 4 BLEN BROFILE MONITOR GENERIC 3 IP 1/0 ADAPTER, SCSI PORT, IPMI PASSTHOUGH RTM 4 VACUUM GUAGE READOUT, REMOTE WAKEUP 1-3 INDUSTRY PACKS (TEWS, Vadatech) RTM 4 VACI-ION PUMP CONTROLLER INTERFACE RTM 4 WIRE SCANNER MOVERS HYTEK IP DESIGN PORT FW, SW FROM XSTG DESIGN 12/01/10 Controls Upgrade Implementation High BW Frame Grabber PMC Adapter GENERIC ADAPTER E.G. VADATECH, TEWS FIBER OPTIC MULTI- GIGABIT LINKS RTM 5 SIMPLE INTERFACE PASSTHOUGH FOR PMC E.G.PROFILE MONITOR HIGH DATA BW FAST FRAME GRABBER AMC 4 PMC ADAPTER (TEWS, Vadatech) 12/01/10 STANDARD PMC BOARD Controls Upgrade Implementation 3. Single Station Upgrade Demo Plan • Proposed staging plan (Station 28-2): – Integrate Controls and RF subsystems separately on identical MTCA platforms – Controls Infrastructure Team supports both with test hardware, firmware, IPMI, low and high level software (in process) – Subsystems integrated, lab-tested separately – Temporary air-water cooled rack installed in 28-2 – Merge tested subsystems in 28-2 – Test each offline, then together online with beam 12-01-10 Controls Upgrade Implementation 17 Single Station Components (Typ.) • Station Control Functions – Klystron-Modulator Interface (MKSUII) • Interlocks & monitoring • Solid state sub booster monitoring • Local displays & controls – Controls & Monitoring (MTCA) • • • • • Status of RF Controller via ADC-DAC RTM Heater & Solenoid power supplies - SLED Tuners MK Interlocks – Vacuum – Temperatures BPMs – wire scanners – profile monitors Network interface to/from modulators 12-01-10 Controls Upgrade Implementation 18 Test Station BD – RF & Accelerator 40ft ACCEL.SECTION INSTRUMENTS & CNTRLS MAIN DRIVE LINE BPMs Toroids Wire Scan Profile Mon. Vacuum Power Supplies BCS Temperature SYNC CLOCKS & LO GENERATION 12-01-10 Controls Upgrade Implementation 19 Station Crate Layout (Typ.) 2 3 4 5 6 7 8 9 10 11 12 t e x t POWER UNIT 1 MCH HUB CONTROLLER & MGR WIRE SCANNER MOVER VACUUM GAUGE VAC-ION PUMP SLOT SPARE ENET INTERFACE TOROID BPM2 BPM 1 FPGA INTERLOCK SUM FAST ADC-DAC 10-2 CH TIMING MODULE IOC PROCESSOR 1 PROFILE FRAME GRABBER t e x t MCH HUB CONTROLLER & MGR t e x t POWER UNIT 1- REDUNDANT PLUG-IN COOLING UNIT (BOTTOM IN – REAR OUT) te xt t e x t PLUG-IN COOLING UNIT (FRONT IN – TOP OUT) Infrastructure Pwr, MCH, IOC, Timing 12/01/10 12-01-10 RF Controls Modules (Typ.) Fdbk Controls Upgrade Implementation Redundant MCH, Pwr Options 20 Side View Crate, AMC, RTM AIR OUT I/ O I/ O INPUT/OUTPUT SIGNAL CONDITIONING FRONT END MODULE text ADVANCED MEZZANINE CARD (AMC) B B A P C K C PL O A N N N E AIR IN REAR TRANSITION MODULE (RTM) USER DEFINED I/O CONNECTORS FAN TRAY-HOTSWAP FAN TRAY-HOT SWAP Note – All I/O in Rear; both AMC, RTM Hot Swappable 12/01/10 12-01-10 Controls Upgrade Implementation 21 MTCA 12-Slot Shelf & Modules 12 Slot Crate & Front-Rear Fan Tray (Schroff) 12/01/10 Controls Upgrade Implementation 6 Slot Crate w/ AMC & RTM (Schroff) 22 Upgraded Station Rack Profile AC POWER PANEL RF IN-OUT RF GENERATION & DOWNMIX MKSUII 9 10 11 12 t e x t POWER UNIT 1 WIRE SCANNER MOVER 8 MCH HUB CONTROLLER & MGR 7 PROFILE FRAME GRABBER 6 VAC-ION PUMP 5 VACUUM GAUGE 4 BPM2 BPM 1 3 ENET INTERFACE FPGA INTERLOCK SUM 2 TOROID TIMING MODULE 1 FAST ADC-DAC 10-2 CH IOC PROCESSOR t e x t POWER UNIT 1- REDUNDANT MTCA CONTROLS MCH HUB CONTROLLER & MGR PLUG-IN COOLING UNIT (BOTTOM IN – REAR OUT) t e x t te xt t e x t PLUG-IN COOLING UNIT (FRONT IN – TOP OUT) SOLENOID POWER SUPPLY HEAT EXCHANGER CROSSCONNECT 12/01/10 12-01-10 Controls Upgrade Implementation CONTROLS IN-OUT 23 In-Rack Crate Enclosure RF CABLES TO/ FROM TRAYS RF GENERATION & DOWNMIX MKSUII 11 12 I/ O I/ O INPUT/OUTPUT SIGNAL CONDITIONING FRONT END MODULE te xt t e x t text ADVANCED MEZZANINE CARD (AMC) B B A P C K C PL O A N N N E AIR IN REAR TRANSITION MODULE (RTM) USER DEFINED I/O CONNECTORS 10 t e x t POWER UNIT 1 9 AIR OUT FAN TRAY-HOTSWAP MCH HUB CONTROLLER & MGR 8 WIRE SCANNER MOVER 7 PROFILE FRAME GRABBER 6 VAC-ION PUMP 5 VACUUM GAUGE 4 BPM2 3 TOROID BPM 1 2 ENET INTERFACE TIMING MODULE FPGA INTERLOCK SUM 1 FAST ADC-DAC 10-2 CH IOC PROCESSOR POWER UNIT 1- REDUNDANT t e x t MCH HUB CONTROLLER & MGR PLUG-IN COOLING UNIT (BOTTOM IN – REAR OUT) t e x t REAR I/O CABLES TO/FROM RTM’S FAN TRAY-HOT SWAP PLUG-IN COOLING UNIT (FRONT IN – TOP OUT) WATER COOLED ENCLOSURE SOLENOID POWER SUPPLY CABLES TO/ FROM TUNNEL 12/01/10 12-01-10 Controls Upgrade Implementation 24 PENETRATION 4. Production & Test Plan • Procurement Controls – All MTCA components except RTMs purchased from vendors – Arrive tested including basic SW, FW – RTMs designed in house relatively simple; vendors will be interested to bid on providing tested units. – Otherwise contract fabrication & test in-house – Rack enclosure with heat exchanger will be contracted to a chassis manufacturer offering the service Controls Upgrade Implementation 12-01-10 25 Generic Application AMC’s • Three AMC’s with RTMs serve all RF needs: 1. Fast ADC DAC AMC module for RF phase, amplitude control and feedback 2. General Analog-Digital Industry Pack (IP) carrier AMC to serve all miscellaneous monitoring and controls 3. PMC Adapter to easily port existing designs in LCLSI • Item 1 delivered & in test; item 2 quote in hand for order; item 3 exists and needs porting to RTM version • Standards Goal: Procure key modules from at least 2 vendors 12-01-10 Controls Upgrade Implementation 26 Struck SIS 8300 RF Digitizer RTM Connector AMC Connector 10 Ch 16 bit 125 MSPS 2 Ch 16 bit DAC output Virtex 5 FPGA 12/01/10 12-01-10 Controls Upgrade Implementation 27 Timing Module – Stockholm U. Timing AMC (University of Stockholm) • • • • Fiber optic links w/ drift compensation ps stability AMC module is receiver and transmitter Clock, trigger and event distribution 12-01-10 Controls Upgrade Implementation Controls Upgrade Implementation 28 Production 2 • RF Chassis (2) – 2 separate chassis are being designed, one with RF circuitry and water-cooled heat sink, the other the MKSUII protection chassis – These are custom units deemed to be not suitable for MTCA packaging partly due to special constraints – Fabrication for quantities will be less amenable to outside fabrication and testing except for ADC-DAC which is MTCA AMC-RTM. – Will seek out vendors who can provide integrated service and back up with in-house shop and production testing. 12-01-10 Controls Upgrade Implementation 29 Production 3 • Pre-test and field integration – Since installing into existing racks, no normal luxury of pre-loading racks in shop, testing before field installation – Will increase Davis-Bacon costs labor in field – All field cable retrofitting done by skilled contractors or SLAC personnel (bad contractor performance on controls cables is a given) – All chassis units fully pre-tested, calibrated before install – Purchased modules and RTMs checked in crate and crate installed – RTM cables prefab & tested before field install – Following slide shows production install flow 12-01-10 Controls Upgrade Implementation 30 GALLERY INFRASTRUCTURE UPGRADE RACKS IN SITU OR PROCURE NEW EEIP RACKS UPGRADE ENCLOSURE LCW HEAT XCHGR CONTROLS PROCURE ALL MODULAR COTS COMPONENTS FABRICATE ALL IN-HOUSE COMPONENTS (CONTRACT) CONVERT CABLE CONNECTORS RF SUBSYSTEM PROCURE ALL MODULAR COTS COMPONENTS FABRICATE ALL IN-HOUSE COMPONENTS (CONTRACT) CONVERT RF INTERLOCK CABLE CONNECTORS POWER CONVERSION CONTROLS & RF CONVERSION PLAN 12-1-10 UPGRADE MODULATOR INTERFACE PREPARE MODULATOR INTERFACE(OLD, NEW) 12/01/10 12-01-10 INSTALL TIMING PREPARE SOLENOID PS INTERFACE INSTALL ENET LOAD CRATES IN ASSY SHOP LOAD RACKS IN SITU(IF XSTG) INSTALL (IF NEW) ATTACH STATION CABLES COMMISSION STATION LOAD RACKS IN PCD ASSY SHOP(IF NEW) Controls Upgrade Implementation 31 Production & Installation Summary • Production and installation scenarios can be highly flexible due to modular nature of accelerator and small chassis and modular assemblies involved – Rack issues in gallery still need work (with PCD) toward optimum solution – cannot grandfather sub-standard units forever – Developing 2 or more vendors for key infrastructure and controls applications modules • In next section T. Himel discusses strategies for changeover within constraints of running LCLS and FACET programs 12-01-10 Controls Upgrade Implementation 32 5. Steps to Installation & Switchover - Contributed by T. Himel 12/01/10 12-01-10 Controls Upgrade Implementation 33 Steps to switchover • First, get all multi-sector or multi-system control of FACET handled by new LCLS style applications (mainly EDM and Matlab) – This was mostly the case for LCLS before our upgrade started. A few had to be moved from old to new. An effort will be required to extend these to FACET, but much smaller than originally doing it for LCLS. The physicists and OPS are used to this and will want FACET to head in that direction anyway. – There are only two ways these applications have to access SLC data: SLCCAS (SLC Channel Access Server) and AIDA. Controls Upgrade Implementation 34 Installation during FACET era • FACET will be running 4 months a year for the next 5 years using sectors 0-20 and the damping rings. • The exact schedule is unknown, but worst case is two 2-month runs each year. (Linac startup time is so long, I cannot imagine more shorter runs.) • These downtimes are too short to install the full upgrade during a single downtime. • Hence we need a way to do partial installs and run FACET with mixture of two control systems. Controls Upgrade Implementation 35 Installation during FACET era • We are doing something similar with the phase I upgrade in sectors 21-30 right now. • It is somewhat easier than what we will be doing for FACET because we only have to move one cable (the CAMAC cable) per sector to switch between old and new control system. It is somewhat harder because LCLS is much less tolerant of downtime than FACET. • We are, however, set up to be able to run LCLS with sectors split between old and new control systems. We will use a similar method for FACET. Controls Upgrade Implementation 36 Steps to switchover • Second, setup a PVgateway to translate PV requests heading towards SLCCAS. – SLCCAS provides read-only access to items in the SLC DB by responding to broadcasts for PVs. – These will be channeled though a PVgateway whose setup can be easily changed to either get the data from SLCCAS or to provide nothing so that the data will instead come from newly installed µTCA IOCs. Controls Upgrade Implementation 37 Steps to switchover • Third, setup AIDA so it can read and write the data it handles from either the new or old control system. (This has been done for klystron and timing control for Phase I) – A small quick DB change is then used to tell AIDA to change which control system it uses to service requests it receives. Controls Upgrade Implementation 38 Steps to switchover • Next, during a long downtime we install new hardware for whatever sectors and systems we have time and budget to do. • We provide EDM screens for detailed control of the new devices. • We modify the PVgateway and AIDA setups to indicate the new hardware should be used. • Checkout as much as we can before FACET turnon. • Schedule check-out time during the FACET turnon • Repeat above steps for other systems/sectors/downtimes until done. Controls Upgrade Implementation 39 END OF SLIDES 12/01/10 12-01-10 Controls Upgrade Implementation 40