Diesel_Dual_Brayton Cycles

advertisement

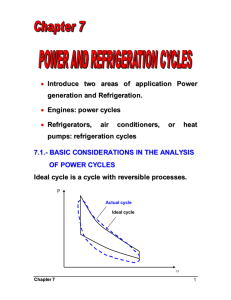

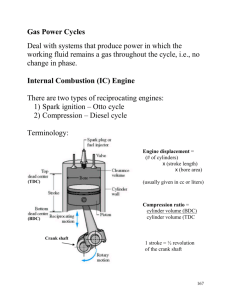

Diesel / Brayton Cycles ASEN 3113 Diesel Cycle • Invented by Rudolf Christian Karl Diesel in 1893 • First engine was powered by powdered coal • Achieved a compression ratio of almost 80 • Exploded, almost killed Diesel • First working engine completed 1894 generated 13 hp Diesel Engine • Also known as Compression Ignition Engine (CI) • Can this engine “knock”? • Difference from Otto Cycle? Thermodynamic Cycles for CI engines • In early CI engines the fuel was injected when the piston reached TDC and thus combustion lasted well into the expansion stroke. • In modern engines the fuel is injected before TDC (about 15o) Fuel injection starts Early CI engine Fuel injection starts Modern CI engine • The combustion process in the early CI engines is best approximated by a constant pressure heat addition process Diesel Cycle • The combustion process in the modern CI engines is best approximated by a combination of constant volume and constant pressure Dual Cycle Early CI Engine Cycle and the Thermodynamic Diesel Cycle Fuel injected at TC A I R Combustion Products Air Actual Cycle Intake Stroke Compression Stroke Power Stroke Qin Diesel Cycle Exhaust Stroke Qout Air BC Compression Process Const pressure heat addition Process Expansion Process Const volume heat rejection Process Process a b Isentropic compression Process b c Constant pressure heat addition Process c d Isentropic expansion Process d a Constant volume heat rejection - a=1,b=2,etc…for book Cut-off ratio: Air-Standard Diesel cycle rc vc v 3 (BOOK ) vb v2 First Law Analysis of Diesel Cycle Equations for processes 12, 41 are the same as those presented for the Otto cycle 23 Constant Pressure Heat Addition now involves heat and work Q P V V2 (u3 u 2 ) ( in ) 2 3 m m Qin (u3 P3v3 ) (u 2 P2 v2 ) m Qin (h3 h2 ) c p (T3 T2 ) m P T v RT2 RT3 3 3 rc v2 v3 T2 v2 AIR Qin 3 4 Isentropic Expansion (u 4 u3 ) W Q ( out ) m m Wout (u3 u4 ) cv (T3 T4 ) m note v4=v1 so v4 v4 v2 v1 v2 r v3 v2 v3 v2 v3 rc P4v4 P3v3 P T r 4 4 c T4 T3 P3 T3 r T4 v3 T3 v4 k 1 r c r k 1 AIR Thermal Efficiency Diesel cycle Qout m u4 u1 1 1 Qin m h3 h2 For cold air-standard the above reduces to: Diesel const cV k 1 1 rc 1 1 k1 r k rc 1 recall, Otto 1 1 r k 1 Note the term in the square bracket is always larger than one so for the same compression ratio, r, the Diesel cycle has a lower thermal efficiency than the Otto cycle So why is a Diesel engine usually more efficient? Thermal Efficiency Typical CI Engines 15 < r < 20 When rc (= v3/v2)1 the Diesel cycle efficiency approaches the efficiency of the Otto cycle Higher efficiency is obtained by adding less heat per cycle, Qin, run engine at higher speed to get the same power. The cut-off ratio is not a natural choice for the independent variable a more suitable parameter is the heat input, the two are related by: k 1 Qin 1 k 1 rc 1 k P1V1 r k = 1.3 W net MEP Vmax Vmin - compares performance of engines of the same size k = 1.3 as Qin 0, rc1 Modern CI Engine Cycle and the Thermodynamic Dual Cycle Fuel injected at 15o before TDC A I R Air Combustion Products Actual Cycle Intake Stroke Compression Stroke Power Stroke Qin Dual Cycle Air Exhaust Stroke Qin Qout TC BC Compression Process Const volume heat addition Process Const pressure heat addition Process Expansion Process Const volume heat rejection Process Dual Cycle Process 1 2 Isentropic compression Process 2 2.5 Constant volume heat addition Process 2.5 3 Constant pressure heat addition Process 3 4 Isentropic expansion Process 4 1 Constant volume heat rejection 2.5 Qin 3 3 2 Qin 4 2.5 4 2 1 1 Qout Qin (u2.5 u2 ) (h3 h2.5 ) cv (T2.5 T2 ) c p (T3 T2.5 ) m Thermal Efficiency Dual 1 cycle Qout m u4 u1 1 Qin m (u2.5 u2 ) (h3 h2.5 ) Dual const cv where rc rck 1 1 1 k 1 r ( 1) k rc 1 v3 v2.5 and P3 P2 Note, the Otto cycle (rc=1) and the Diesel cycle (=1) are special cases: Otto 1 1 r k 1 Diesel const cV 1 1 rck 1 1 k 1 r k rc 1 The use of the Dual cycle requires information about either: i) the fractions of constant volume and constant pressure heat addition (common assumption is to equally split the heat addition), or ii) maximum pressure P3. Transformation of rc and into more natural variables yields rc 1 k 1 Qin 1 1 k P1V1 r k 1 k 1 1 P3 r k P1 For the same initial conditions P1, V1 and the same compression ratio: Otto Dual Diesel For the same initial conditions P1, V1 and the same peak pressure P3 (actual design limitation in engines): Diesel Dual otto Brayton Cycle • Introduced by George Brayton (an American) in 1872 • Used separate expansion and compression cylinder • Constant Combustion process Brayton Cycle 18 Other applications of Brayton cycle • Power generation - use gas turbines to generate electricity…very efficient • Marine applications in large ships • Automobile racing - late 1960s Indy 500 STP sponsored cars Schematic of simple cycle Idealized Brayton Cycle Brayton Cycle •1 to 2--isentropic compression •2 to 3--constant pressure heat addition (replaces combustion process) •3 to 4--isentropic expansion in the turbine •4 to 1--constant pressure heat rejection to return air to original state 22 Brayton cycle analysis • Because the Brayton cycle operates between two constant pressure lines, or isobars, the pressure ratio is important. •The pressure ratio is not a compression ratio. Efficiency: Net work: w net q in w net w turb w comp Brayton cycle analysis 1 to 2 (isentropic compression in compressor), apply first law **When analyzing the cycle, we know that the compressor work is in (negative). It is standard convention to just drop the negative sign and deal with it later: wcomp h2 h1 24 Brayton cycle analysis 2 to 3 (constant pressure heat addition treated as a heat exchanger) q in q 23 h 3 h 2 3 to 4 (isentropic expansion in turbine) w turb h 4 h 3 , or w turb h 3 h 4 25 Brayton cycle analysis 4 to 1 (constant pressure heat rejection) q out h1 h 4 , We know this is heat transfer out of the system and therefore negative. In book, they’ll give it a positive sign and then subtract it when necessary. q out h 4 h1 26 Brayton cycle analysis net work: w net w turb w comp Substituting: w net (h 3 h 4 ) (h 2 h1 ) Brayton cycle analysis Thermal efficiency: w net (h 3 h 4 ) (h 2 h1 ) q in (h 3 h 2 ) (h 4 h1 ) 1 (h 3 h 2 ) Brayton cycle analysis assume cold air conditions and manipulate the efficiency expression: 1 c p (T4 T1 ) c p (T3 T2 ) T1 T4 T1 1 1 T2 T3 T2 1 Brayton cycle analysis Using the isentropic relationships, T2 p 2 T1 p1 k 1 k ; T4 p4 T3 p3 k 1 k p1 p2 k 1 k Define: P2 P3 rp pressure ratio P1 P4 30 Brayton cycle analysis Then we can relate the temperature ratios to the pressure ratio: T3 T2 k 1 k rp T1 T4 Plug back into the efficiency expression and simplify: 1 1 k 1 k rp Brayton cycle analysis 32 Brayton cycle analysis An important quantity for Brayton cycles is the Back Work Ratio (BWR). BWR w comp w turb The Back-Work Ratio is the Fraction of Turbine Work Used to Drive the Compressor EXAMPLE PROBLEM The pressure ratio of an air standard Brayton cycle is 4.5 and the inlet conditions to the compressor are 100 kPa and 27C. The turbine is limited to a temperature of 827C and mass flow is 5 kg/s. Determine a) the thermal efficiency b) the net power output in kW c) the BWR Assume constant specific heats. Draw diagram P 2 3 1 4 v Start analysis Let’s get the efficiency: 1 1 k 1 k rp From problem statement, we know rp = 4.5 1 1 1.41 1.4 4.5 0.349 Net power output: Net Power: Ýnet m Ýw net m Ý w turb w comp W Substituting for work terms: Ý m Ý(h3 h4 ) (h2 h1) W net Applying constant specific heats: Ýnet m Ýc p (T3 T4 ) (T2 T1) W Need to get T2 and T4 Use isentropic relationships: p2 T2 T1 p1 k 1 k p4 T4 T3 p 3 ; k 1 k T1 and T3 are known along with the pressure ratios: T2: T2 3004.5 461 K 0.4 1.4 T4: T4 11000.222 0.4 1.4 715.7 K Ýnet m Ýc p (T3 T4 ) (T2 T1) W Net power is then: W net 1120 kW Back Work Ratio BWR w comp w turb h 2 h1 h3 h4 Applying constant specific heats: T2 T1 461 300 BWR 0.42 T3 T4 1100 715.7 Brayton Cycle • In theory, as the pressure ratio goes up, the efficiency rises. The limiting factor is frequently the turbine inlet temperature. • The turbine inlet temp is restricted to about 1,700 K or 2,600 F. • Consider a fixed turbine inlet temp., T3 Brayton Cycle • Irreversibilities – Compressor and turbine frictional effects cause increase in entropy – Also friction causes pressure drops through heat exchangers – Stray heat transfers in components – Increase in entropy has most significance • wc = h2 – h1 for the ideal cycle, which was isentropic • wt = h3 – h4 for the ideal isentropic cycle Brayton Cycle • In order to deal with irreversibilities, we need to write the values of h2 and h4 as h2,s and h4,s. • Then w t ,a h 3 h 4,act t w t ,s h 3 h 4,s w c ,s h1 h 2,s c w c ,a h1 h 2,act