Walls201314 - Trinity College Dublin

advertisement

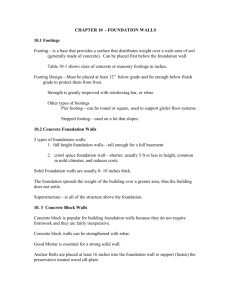

Walls I 3A9 Construction Technology S Pavía Dept of Civil Engineering Trinity College Dublin contents • • • • Types of walls Strength of walls Strength requirements crushing, buckling, settling, overturning Types according to construction • Solid – Masonry- building units and mortar built in horizontal layers (courses). • Solid brick-single leaf • Solid block • Stone – Monolithic- one single material initially requiring support ie concrete • Cavity- double leaf and cavity • Frame- frame of members with facing or sheeting e.g. timber. • Membrane- sandwich of 2 skins of reinforced plastic, metal or plywood attached to plastic core or ribs. Light weight, high strength. • Curtain wall - outer covering, non-structural but merely to protect from the weather. Solid Walls Brick Wall Stone Wall Concrete Block Wall Solid Walls Clay walls Solid Wall – Concrete Solid Wall -Innovative Materials Hemp and lime Straw bale Cavity Walls Wall ties built into cavity walls are intended to share lateral forces and deflections between the 2 leaves. Frame Frames consist of horizontal elements (beams, plates) and vertical elements (columns, studs) connected by joints. Cladding application of one material over another to provide a wall around a frame or for aesthetic purposes Advantages and Disadvantages • Solid – Stronger (The strength of a 255 mm cavity wall with loads spread over both leaves is 20% less than that of a one-brick wall). – Higher thermal mass • Cavity – Prevents damp penetration – Insulation can be added to cavity • Frame – Fast construction – Low labour costs Functions and requirements - external walls • To enclose space • To support upper floors and roofs together with the loads that will be imposed upon them- domestic / industrial ADEQUATE STRENGTH AND STABILITY • To resist damp penetration and biological colonisation DAMP PROOF MEMBRANES / UNDER-FLOOR VENTILATION. • To provide an adequate insulation to reduce heat loss INSULATORS / THERMAL BRIDGING • To offer adequate resistance to fire and the environmentrain, wind DURABLE , FIRE RESISTANT MATERIALS / BOND STRENGTH • To look attractive and accommodate windows and doors Types according to function • Loadbearing- support loads from floors and roof in addition to their own weight, resist side pressures from wind - sometimes, from stored objects. • Non-loadbearing- carry no loads. • Partition- Internal -either loadbearing or not-, divide the space within a building. • Compartment- separate internal space for fire protection. • Internal- separate adjoining buildings e.g terrace houses. • Separating- separate single occupancies within the same building or different buildings. • Retaining- support and resist the horizontal forces caused by retained earth or subsoil water. Parapet Wall • Parapet- upper part of external wall carried above the level of a roof plane or a roof gutter. Retaining Wall • provide lateral support to vertical slopes of soil built in order to hold back earth which would otherwise move downwards. • stability depends on: maximum lateral earth (horizontal) pressure. lateral pressures depend on the moisture content of the soil overturning, base sliding, soil bearing capacity failure Gravity, piling, cantilevered, butressed, anchored Gravity Walls – Depend on their own weight and any soil resting on the concrete in resisting lateral earth forces. – Usually they are sufficiently massive to be unreinforced. – The mass of the structure must be sufficient to develop enough frictional resistance to sliding – The base or footing of the structure must be wide enough to develop sufficient moment to resist overturning earth forces Cantilever Retaining Wall • Constructed of reinforced concrete: relatively thin stem and a base slab. • Use less concrete than gravity walls but require more design and careful construction. • They gain a larger effective mass due to the soil placed on the horizontal cantilevered section of the wall. Buttressed/Counterfort Retaining Walls • similar to cantilever walls except for the buttresses along the back of the wall to improve its strength resisting high loads. Piling Wall •used in soft soils and tight spaces. •typically made of reinforced concrete or steel driven into the ground. •usually driven 1/3 above and 2/3 below ground, •tall sheet pile walls will need a tie-back or anchor behind the face of the wall, that is tied to the wall, usually by a cable or a rod. Anchored Wall An anchored retaining wall can be constructed in any of the aforementioned styles Additional strength is provided by cables or other stays anchored in the rock or soil behind it. Technically complex, very useful where high loads are expected, or where the wall itself has to be slender and would otherwise be too weak. Diaphragm Wall • generally a reinforced concrete wall constructed in the ground in areas of soft earth close to open water or with a high ground water table i.e. surrounding tunnels, car parks and open cuts. – Built up areas – Suited for deep basements Diaphragm Walls Fix alignment with guide walls Trench excavated in discontinuous sections Fill trench with slurry (bentonite) which provides hydraulic pressure to the trench walls and prevents trench collapsing Insert reinforcement cage into trench Fill with concrete, displacing slurry Strength requirements of walls • Strength is determined by design: – strength of material, – wall thickness, – height/thickness, – lateral support. • Under a vertical load a wall may crush, buckle or settle • A horizontal load may cause overturning • The design of loadbearing members must ensure that the design strength is greater than the design load Crushing • The wall must be of sufficient thickness to keep the stresses within the safe compressive stress limits of the materials to avoid crushing by overloading. • In small scale buildings of masonry construction thickness is rarely determined by strength alone as the load of (e.g.) a two storey building is quite small, well within the bearing capacity of a normal half-brick wall. • A material crushes when the compressive strength load exceeds the strength of the material. Buckling • Buckling is the failure of a structural member by applied axial load causing excessive lateral deflection at a stress lower than the crushing stress • Imperfections in the material, off-centre application of loads Buckling usually occurs in etc… can induce secondary slender members with a bending and buckling in a high height/thickness ratio material the greater the ratio the highest the tendency to buckle. Buckling • Provide lateral support to walls by adequately bracing floors and roof. • Connections to floors and roofs by means of tension straps and joist hangers are needed to provide horizontal lateral restraint and be capable of resisting lateral loads Must have a base wide enough so that the wall load is distributed over a sufficiently large area of soil - for not to exceed the stress limit of the soil and avoid failure by settlement. Settlement Settlement • Limit the width of openings in order to provide sufficient wall bearing area to ensure strength and stability. • Provide lateral support to walls by adequately bracing floors and roof. Provision of an extended foundation strip HORIZONTAL LOADS - SLIDE / OVERTURN • Provide the weight necessary to provide stability and avoid slidingincrease height or thickness. • friction and the passive pressure of the soil on which the wall rests prevent sliding. weight sliding Passive pressure of soil friction OVERTURN • Increase wall weight or width of base (trapezoidal walls) to avoid overturning by rotation induced by an overturning force. • Adequate lateral support to resist overturningbuttresses, fins, struts. Overturning by rotation Overturning by settlement Overturning by settlement Overturning Adequate lateral support to resist overturningbuttresses, fins, struts. Flying buttresses Bonding of masonry units will restrict buckling, differential settlement and overturning. Strong masonry bond to withstand tensile stresses induced by unequal loading-eccentric loading. Openings • Load must be transferred from over an opening to the surrounding wall ie lintels in the case of windows • Limit the width of openings in order to provide sufficient wall bearing area to ensure strength and stability. Removing internal partition walls • Determine if wall is load bearing • If load bearing wall, the load must be transferred to another load bearing element with enough strength capacity to carry the additional load Openings No Lintel Lintel Arch Wall Openings-Terms • Jamb-wall immediately adjacent to the side of the opening – Reveal-return face to the jamb – Square jamb- the reveal is flat – Rebated jamb-the reveal is recessed. • Head-supports the wall above opening-lintel or arch. – Soffit-return face to the head. • Cill-bottom of a window opening. • Threshold-bottom of doorway (J S Foster 1994) Internal walls • Primary function to act as a vertical divider of floor space forming a storey height enclosing element. • Other functions Basic design concepts for internal walls • Load bearing -those which accept and transmit structural loads to the foundations. • Partitionssupport only their own self weight and do not accept any structural loads. Chudley and Greeno 1988 Ceiling /floor joists transmit loads to wall Roof struts transmit loads to wall Strength of walls • It depends on the strength of its materials and the strength of the bond between them. • Materials must be durable- testing: thermal, freeze /thaw and salt crystallization cycling . • Physical properties of different materials in the wall must be compatible-combinations permeable/impermeable; strong/weak unsuitable for long-term durability. • Chemical composition of different materials in the wall to also be compatible. Code of Practice for the use of masonry- part 1Structural use of unreinforced masonry BS 5628-1:2005 Design of walls: objectives & recommendations. The design of loadbearing masonry members must ensure that the design strength of a member is greater than or equal to the design load. The factor γm makes allowance for the variation in the quality of the materials and for the possible difference between the strength of masonry constructed under site conditions and that of specimens built in the laboratory. Partial safety factors for loads (γf) are introduced to take account of: a) possible unusual increases in load beyond those considered; b) inaccurate assessment of effects of loading, unforeseen stress redistribution within the structure; c) the variations in dimensional accuracy achieved in construction. The design recommendations assume that all the lateral forces acting on the whole structure are resisted by walls, or by suitable bracing. a) buildings should be designed to be capable of resisting a uniformly distributed horizontal load equal to 1.5 % of the total characteristic dead load b) Connections to floors and roofs by means of tension straps and joist hangers are needed to provide horizontal lateral restraint and be capable of resisting lateral loads –appendix detail drawings. Strength of walls • Loads: the following should be used as characteristic loads. – a) Characteristic dead load. The characteristic dead load Gk is the weight of the structure complete with – finishes, fixtures and partitions and should be taken as equal to the dead load as defined in and – calculated in accordance with BS 6399-1. – b) Characteristic imposed load. The characteristic imposed load Qk should be taken as the imposed load – as defined in and calculated in accordance with BS 6399-1 and BS 6399-3. – c) Characteristic wind load. The characteristic wind load Wk should be taken as the wind load calculated – in accordance with BS 6399-2. • The strength of a 255 mm cavity wall with loads spread over both leaves is 20% less than that of a one-brick wall. – Wall ties built into cavity walls are intended to share lateral forces and deflections between the 2 leaves. • EN 8103 design of low-rise buildings. It includes permissible stresses for load-bearing walls and prescribes their minimum thickness (determined in relation to the load to be carried). • Thickness not only determined by strength but also by weather and fire resistance and thermal insulation. Strength requirements Walls transfer applied loads to the ground • Self-weight loads (EN 1991-1-1:2002) the total self-weight of structural and non-structural members including finishes, fixtures and partitions • Imposed loads (EN 1991-1-1:2002) loads on buildings arising from occupancy including – normal use by persons; – furniture and moveable objects (e.g. moveable partitions, storage, the contents of containers); - vehicles; – anticipating rare events, such as concentrations of persons or of furniture, or the moving or stacking • Wind load (EN 1991-1-4:2005) Load applied to a building due to wind • Other loads include snow, fire, accidental such as impacts and explosions. Eurocodes • • • • • • • • • • Eurocode BS EN 1990:2002 Basis of structural design Eurocode 1 BS EN 1991-1-1:2002 Actions on structures. Eurocode 2 BS EN 1992-1-1:2004 Design of concrete structures. Eurocode 3 BS EN 1993-1-1:2005 Design of steel structures. Eurocode 4 BS EN 1994-1-1:2004 Design of composite steel and concrete structures. Eurocode 5 BS EN 1995-1-1:2004 Design of timber structures. Eurocode 6 BS EN 1996-1-1:2005 Design of masonry structures. Eurocode 7 BS EN 1997-1:2004 Geotechnical design. Eurocode 8 BS EN 1998-1:2004 Design of structures for earthquake resistance. Eurocode 9 BS EN 1999-1-1:2007 Design of aluminium structures.