it does not manage the separate thrust between the two

SWING GATE OPERATORS

AMI A180

ATI A3/5000

FAST F7001

SLIDING GATE OPERATORS

BXA

BXB

CONTROL BOARDS

ZA3 for swing leaf

ZF1 for swing leaf

ZM2 for swing leaf

Container for boards

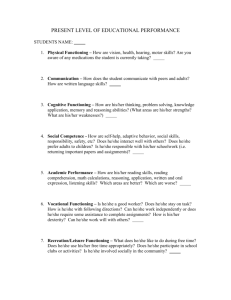

FEATURES

Model

IP 54 PROTECTION

AMI A 180

Declared

Housing protection IP54 real

IP42

IP 5.. Protected against dust:

Dust penetration is not totally excluded but the quantity of dust which can penetrate will not obstruct good functioning of material.

IP.. 4 Protected against water jet:

Water spraid on the cover from all directions must not cause harmful consequences.

IP 54 PROTECTION

??

Terminal board connection

Stator

Limit switch

230V power supply

PROTECTION COVER

The protection cover manufactured in this way and not fitted with gaskets presents a very low protection on all the reduction group.

ELECTRICAL LIMIT SWITCH

Electrical limit switch only in opening, IT WORKS ONLY IN MOTOR

PHASE, PROTECTION LEVEL IP20.

There is no indication regarding limit switch in the instruction manual: its use is not mentioned and neither its setting range

MANOEUVRE SCREW

The manoeuvre screw is made of normal steel and has been normally burnished as a proctective treatment.

This kind of treatment is to be used only for components which are in the internal part of products. Moreover such treatment is usefull only for storing phase before the assembling phase.

PROOF ON SCREEW AMI A 180

A functioning test has been carried ou on gate LP001 - leaf of 2 meters - weight of 360 kg.

Date of beginning: 23-09-04

Date of proof end: 25-10’04 after 26.510 cycles

The operator is not functioning because the front bracket get broken.

Not only the bracket get broken but also the complete reduction group. Replacement of all the operator is necessary.

Alternatively, we have to disassemble all the front part in order to replace the motor cover opening the operator???

FEATURES

Model

IP 54 PROTECTION

ATI A3/5000

Declared

Protection degree IP54 real

IP43

IP 5.. Protected against dust:

Dust penetration is not totally excluded but the quantity of dust which can penetrate will not obstruct good functioning of material.

IP.. 4

.

Protected against water jet:

Water spraid on the cover from all directions must not cause harmful consequences

IP 54 PROTECTION

MOTOR CABLE CONNECTION AND

RELATIVE TEARING RESISTANCE

Normative laws expressly request that “the devices must be fitted with cable fixing devices in order to enable that conductors are protected against traction and torsion force … …” . Above rules have not been followed in

ATI product. In this case, the cable has been put inside the fusion making some curves in order to obtain a certain resistance to traction. ABO

VE

PRODUCT IS NOT CONFORM TO THE RULES.

Moreover, motor cable connection is not mentioned in the CAME instruction manual; there is only a diagram for terminal board connection

Cable entrance cable exit

MOTION TRANSMISSION BETWEEN ROTOR

AND EPICYCLOID RIDUCTION

Motion transmission between rotor and epicycloid through gasket made of plastic and

NOT WITH THE PROPER

DIMENSIONS

ELECTRICAL LIMIT SWITCH

Electrical limit switch that operates, in 230V version, on MOTOR

PHASE, PROTECTION LEVEL IP 20.

CAME does not mention in any documentaion that actuators for

230V version are fitted with limit switch in opening.

Whereas it seems that in 24 V version the actuators are fitted with stop and slow-down limit switch in opening and only slow-down limit switch in closing ( we know it from the instruction but we have to investigate this matter)

MANOEUVRE SCREEW

The manoeuvre screw is made of normal steel and has been normally burnished as a proctective treatment.

This kind of treatment is to be used only for components which are in the internal part of products. Moreover such treatment is usefull only for storing phase before the assembling phase.

LIFE PROOF ON ATI 5000

Functioning test has been carried out on LP011 gate, 4-meter leaf,

weight: 250 kg.

Date of beginning: 1st test on 17-12’04

End of test

22-12-’04 after 2.217 cycles after GASKET

BREAKING

We have purchased the spare parts and resume the test on internal gate LP002 with 2,5-meter leaf and weight kg. 210 ( NB. We did not use the external gate because it was in use for other UT test)

Date of beginning 2nd test on 04-03’05

End of test 07-03-’05 after 1.350 cycles after GASKET

BREAKING

NB. The proof will be repeated in April with ATI A3000 actuator in order to check if the GASKET BREAKING is due to a production defect

Mode

FEATURES

Housing protection

IP 54 PROTECTION

FAST 7001

Declared

IP54

Real

IP33

Terminal board connection

Inside part of reductor

MOTOR CABLE CONNECTION AND

RELATIVE TEARING RESISTANCE

Normative laws expressly request that “the devices must be fitted with cable fixing devices in order to enable that conductors are protected against traction and torsion force … …”

Above rules have not been followed with FAST product; a rubber membrane is used and it does hold the cable

LIFE PROOF ON FAST F7001

We have carried out a functioning test on LP001 gate with 2-meter leaf and weight 360 kg.

Date of beginning 16-09-03

Date end of test 16-12’03 after 61.000 cycles

The tow pin got broken

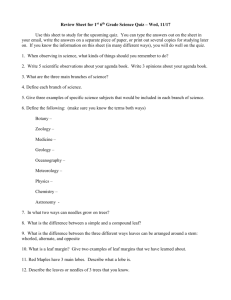

FEATURES

Model

IP 54 PROTECTION

BXA - BXB

Declared Real

Housing protection IP54 IP43

Coupling of the two covers does not assure any air or water seal; moreover control board is not protected

FREQUENCE OF USE

Model

FEATURES

BXA kg. 400

Decl.

real

Falcon 5

BXB kg. 800**

Decl.

Real Decl.

Real.

Falcon 8

Decl.

Real.

Housing protection

Frequence

IP54

30%

IP43

10%

IP44

30%

IP44

30%

IP54

30%

IP43

10%

IP44

** BXB model is declared to be for residential use with 600-kg leaf

HOW COULD IT BE POSSIBLE WITH A FREQUENCE OF 10% ??

40%

IP44

40%

FUNCTIONING PROOF IN CONTINUOUS DUTY

POWER SUPPLY 230V -- AMBIENT TEMPERATURE +25 ° C

BXA KG. 400

3’ 50”

Falcon 5 kg. 500

10’ 30”

BXB KG. 800

5’ 17”

Falcon 8 kg. 800

Oltre 22’

FURTHER DETAILS

Limit switch not protected

Stator not protected

Painting has not been done

Beginning of corrosion during proof IP44

24 hours of normal rain

Beginning of corrosion after proof IP44

ZF1 CONTROL BOARD

Control board with few functions, the only two important features are the pilot lamp and the electric lock

IT DOES NOT HAVE THE RESIDENTIAL FUNCTION

IT DOES NOT HAVE ANY INPUTS FOR PHOTOCELLS IN OPENING

AND CLOSING

IT DOES NOT CONTROL THE SEPARATED THRUST BETWEEN

THE TWO MOTORS

IT DOES NOT HAVE THE FUNCTION “SEPARATED WORK TIME

BETWEEN THE TWO MOTORS”

IT DOES NOT MANAGE DECELERATION

IT DOES NOT HAVE THE PARTIAL OPENING

IT DOES NOT HAVE ANY INPUTS FOR ENCODER

IT DOES NOT HAVE ANY INPUTS FOR LIMIT SWITCH

IT IS NOT POSSIBLE TO CONTROL INVERSION STROKE AND

OVER PUSHING STROKE WITH THE ELECTRIC LOCK

ONLY ONE COMMON FOR SEVERAL CABLES IN INPUT

MAXIMUM MOTORS LOAD: 320W

TRANSFORMER MUST BE PURCHASED SEPARETELY

IT DOES NOT HAVE ANY INPUT FOR

PHOTOCELLS IN OPENING AND CLOSING

It has only one input for the photocells; it works only with the following logic: reopening during closing phase of leaves without any other logics available.

Otherwise photocells must be connected to stop input: in this case, it stops the leaves motion.

IT DOES NOT MANAGE THE SEPARATE

THRUST BETWEEN THE TWO MOTORS

It is not possibile to set the separated thrust in presence of two motors

There are only 4 levels of force setting: to be made moving the faston on the transformer

IT DOES NOT HAVE SEPARATE WORK TIME

BETWEEN THE TWO MOTORS

It is not possible to set separate work time on the two leaves

IT DOES NOT MANAGE

DECELARATION

It is not fitted for decelaration in opening and closing

ONLY ONE COMMON FOR SEVERAL INPUTS

The connection of two motors and flashing lamp must used the same “W”

All the accessories must be connected to a sole input “2”

ZA1 CONTROL BOARD

This control board can be compared to Brain 574 model and surely not to Brain 592 model

Series of separated inputs such as “opening push button”, “closing push button”, “partial opening push button” and input 2-7 for transmitters for automatic logics management.

It is possibile to have safeties both in opening contact

C-1 and in closing contact 2-CX (in this case 2 logics can be selected through dip-switch 8 “Re-closing during opening and Partial stop”).

Separate input of Stop 1-2

Output for electric lock

Compared to Brain 574

IT DOES NOT MANAGE SEPARATE THRUST BETWEEN THE TWO

MOTORS

IT DOES NOT HAVE WORK TIME SEPARATED BETWEEN THE

TWO MOTORS

IT DOES NOT MANAGE THE DECELERATION

SETTING LEAF DELAY IN PARTIAL OPENING PARZIALE CON UN

SOLO TRIMMER TR2M

ONE SOLE COMMON FOR SEVERAL CABLES IN INPUT

MAX MOTORS LOAD 600W

TRANSFORMER MUST ALWAYS BE PURCHASED SEPARATELY

Further details if compared with Brain 592

IT DOES NOT HAVE INPUTS FOR ENCODER

IT DOES NOT HAVE INPUTS FOR LIMIT SWITCH

IT IS NOT POSSIBLE TO MANAGE INVERSION STROKE

ZM2 CONTROL BOARD

This control board can be compared to

Brain 592 model

ZM2 control board is almost identical to

ZA3 model, in addition :

Separate inputs for the limit switch

ON-OFF function of autotest on the safeties; to use this function, photcells must be connected through a certain diagram

Addition of a dip-swith with two inputs in order to increase some functions such as partial opening and pedestrian opening

Compared to Brain 592

IT DOES NOT MANAGE THE SEPARATE THRUST

BETWEEN THE TWO MOTORS

IT DOES NOT HAVE THE SEPARATE WORK TIME

BETWEEN THE TWO MOTORS

IT DOES NOT MANAGE THE DECELERATION

SETTING OF LEAF DELAY AND PARTIAL OPENING

WITH ONLY ONE TRIMMER TR2M

ONE SOLE COMMON FOR SEVERAL CABLES IN

INPUTS

MAX. MOTORS LOAD 600W

TRANSFORMER MUST ALWAYS BE PURCHASED

SEPARATELY

IT DOES NOT HAVE ANY INPUTS FOR ENCODER

IT IS NOT POSSIBLE TO CONTROL THE INVERSION

STROKE

CONTAINER FOR BOARDS

WITH TRANSFORMER

IP54 PROTECTION DEGREE

A grid has been put for air circulation but it can not guarantee the IP 54 protection

The two covers are closed with only two screws on the hole

No gasket along the edges

IP54 PROTECTION DEGREE

H2O

CONCLUSIONS

Quality of the container is quite low and its IP42 protection degree, against a IP54 declared degree, causes functioning problems for the control boards

The closing with only two thread screws in the bottom part: it is not enough to guarantee the tightness.

Morevorer, it is hard to garantee a IP54 degree, protection against water jet from all directions, putting a grid on the container for air ventilation.

Besides, there are no gaskets.

IP 54

Protection against dust:

Dust Penetration is not totally excluded but the quantity of dust which can penetrate will not obstruct good functioning of material.

Protection against water jet:

Water spraid on the cover from all directions must not cause harmful consequences

SWING OPERATORS

Pluto PL4005

Moby 4006

WingoKit

Popkit

SLIDING OPERATORS

Robo 1010

IP43 PROTECTION

Model

FEATURES

Protection degree

Decl.

Real

IP43 IP42

All the three models present the same problem of water entrance: you just have to see the holes in the bottom part of the cover to understand the problem.

PLUTO PL4005

A 4- mm piece can be easily fit inside the casing

The first value, which refers to solid pieces, states level 4 “Protected against solid pieces larger than 1 mm thin tools,thin threads”; as shown in the pictures the chink is larger than 1 mm being around

4mm: therefore real level should be 2 instead of 4. Besides the chink causes the water penetration; therefore the second value “Protection from liquids” should be also at level 2

MOBY 4006

WINGOKIT

MANOEUVRE SCREW IN NORMAL STEEL

The manoeuvre screw is made of normal steel and the protection is guaranted with only grease with which it is lubricated initially (we remind you that the manoeuvre screws used by Genius (for external use) are only made of

STAINLESS STEEL)

PLUTO

WINGO

MOBY

THE EXCLUSIVE Nice RELEASE EASY

TO OPEN

The exlcusive Nice release is surely easy to use but unfortunately it must always stay up. But it is not good for water tightness. In order to assure water tightness, release must be closed at each movement.

Position that release should have when it is open

PLUTO

M

O

B

Y

WINGO

LIFE PROOF ON PLUTO PL 4005

Functioning test carried out on LP011 gate with 2,50 m-leaf and weight 200 kg

Date of beginning 15-09-03

Date of end proof 05-12’03 after 54.800 cycles after breaking of lead bracket

LIFE PROOF ON WINGO WG4000

Functioning test carried out on gate LP011 leaf 2,50 m weight

200 kg

Date beginning 04-02’04

Date end of proof 09-06’04 cycles 45.000, operator still functioning

We note an increase of noise and increase of slack in the lead nut: this model is the most performing among the three models

LIFE PROOF ON MOBY MB 4006

Functioning test carried out on gate LP011 leaf 2,50 m weight

200 kg

Date of beginning 05-12’03

Date of end proof 02-02’04 after 26.425 cycles after breaking of lead bracket

IP 43 PROTECTION

The carter is closed with only two rear screws. IT IS NOT POSSIBLE to guarantee tightness

GASKET

The closing screws of the two aluminium covers do not have the right dimension; infact, the two covers can moove causing the wear of the gasket

IP 43 PROTECTION

How does Nice intend water tight: the water goes in and goes out

LIFE PROOF ON POPKIT

Functioning test carried out on gate LP001 leaf of 2 mt weight

160 kg

Date of beginning 17-12’03

Date of end 07-01’04 after 11.343 cycles for breaking of aluminium COVER

COMPARISON NICE / GENIUS

Model

FEATURES

Protection degree

Frequence of use

ROBO 1010 real

IP43

30%

Falcon 5 real

IP44

30%

Falcon 8 real

IP44

40%

FUNCTIONING PROOF IN CONTINUOUS DUTY

POWER SUPPLY 230V -- AMBIENT TEMPERATURE +25 ° C

Falcon 5 kg. 500

10’ 30”

RO1010

15’ 30” Falcon 8 kg. 800

Oltre 22’

FURTHER QUALITIES ABOUT

NICE

Position of capacitor

Protection of stator

FURTHER QUALITIES ABOUT NICE

Position of capacitor

Protection of stator

Limit switch

FURTHER QUALITIES ABOUT NICE

Board cover

Gear motor fixing with only two screws

CONTROL BOARD

Max. load accessories 200 mA - Genius 500 mA

IT CAN NOT MANAGE ENCODER

Pedestrian opening/partial opening on with additional board PIÙ

One input for photocells/safety edge in opening

(Genius: separated inputs for photocells in opening, closing and edge)

Photocell in closing: optional only with board PIÙ

Only one common with difficulties to connect several accessories (Genius: several inputs for each common)

FAILSAFE optional, managed with board PIÙ

UNDER ANALYSIS

Prince 24V

President

ELECTRONIC BOARD

KS2 24V

ANTI-INTRUSION ALARM

The PRINCE 24 PLUS connected to electronic board KS2 24V enable to obtain a antiintrusion alarm system ABIS (patented): this system detects each attempt of opening the gate with force from ill-intentioned people. The board detects the attempts of forced opening of the gate and it operates automatically the motors in closing in order to resist to movement. Simultaneously it puts into action an alarm siren (optional) in order to signal the intrusion attempt

RIB presents this solution like a EXTRA feature but it is the only solution since the

PRINCE operator

IS NOT IRREVERSIBLE as it is stated in the price list, but it is REVERSIBLE .

In fact, it is a epicycloid reduction with direct drive, in which the shutdown is obtained through the board making a bu-pass on the motor; this solution does not assure the stop and it compells the reduction gears to support all the thrust load causing big problems of functioning

RIB was obliged to use with this operator a control board which enables leaf block: and then the idea of alarm anti-intrusion ABIS system came out.

ANTI-INTRUISION SYSTEM

THIS SYSTEM DOES NOT FOLLOW THE SAFETY STANDARDS

Safety standards state that the maximum thrust, under 500 mm of space, must be 400N for 0,75 sec and then going down to ZERO within 5 seconds.

LET’S IMAGINE THAT A CHILDREN, WHILE

PLAYING, PUSHES THE CLOSEN LEAF. THE

LEAF GET OPENED OF FEW CENTIMETERS, HIS

FINGERS STAY BETWEEN THE TWO LEAVES

AND THE ACTUATOR STARTS PUSHING WITH

ALL THRUST. THE TRAPPED CHILDREN CAN

NOT TAKE OFF THE FINGERS BECAUSE WHEN

HE TRIES TO OPEN THE LEAF, THE ACTUATOR

MAKE RESISTANCE WITH MAXIMUM THRUST.

SIMPLIFIED INSTALLATION, NO NEED TO SET …. THE

LIMIT SWITCH POSITION

•

•

IT DOES NOT REPEAT THE

POSITIONING ON THE STROKE

FIXED ADJUSTMENT OF THE

STANDSTILLS

REPEATIBILITY

BECAUSE THE

SYSTEM DOES NOT ENABLE THE

ONLY ONE VERSION: NO RIGHT AND

LEFT MODELS

Positioning of two opposite beams

Positioning of two opposite beams

Internal release and external release

LIFE PROOF

In the normal functioning, all the problems of oxidation have to be considered:

torque spring: it is not protected and it is made of steel

output shaft: it does not have any O rings and the water can enter the kinematic motion

NB. The product functioned for two months only in

Laboratory without being esponed outside, as it should be for its normal use

SENSIBILITY OF POWER SENSOR

The sensibility of the power sensor which is indicated for all the operators without encoder , appears to be not very functional with problems of calibration since it is not an ajustable value.

In fact, the adjustment, which has to be made in programming phase, settles (through a Trimmer) the sensor at the minimum DL3 switch off, when the operator arrives to the end of its stroke, you have to rotate the trimmer in counterclock wise until the DL3 led switches on.

.

From the proofs we have carried out, it comes out the the sensibility is two high: a light movement or oscillation is considered like an obstacle; it is NOT possible to adjust the value rotating the trimmer because in this case when the operator arrives at the end of its stroke,

DL3 led does not switch on and then nothing is functioning any more.

Nb. We remind you that the Genius/FAAC board has 4 degrees of sensibility

ENCODER SENSIBILITY

The encoder sensibility in the obstacle detection does not have any levels/threshold, but it learns from the default value and IT IS NOT POSSIBLE to modify the value.

FURTHER DETAILS

It can not manage the limit switches

Pedestrian is optional using Expander board

No separate inputs for safety in opening and closing, Optional with Expander board

Circuit for battery charge not integrated in the board but supplied separately

When only one leaf is used, you have to cut a jumper; then, in order to come back to the use of two leaves, you have to weld the jumper or to change the board ( Genius manages without any problems the use from single leaf to double leaf )