Syllabus - Heartland Community College

advertisement

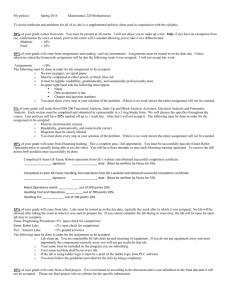

Heartland Community College Technology Division Course Syllabus for Students Spring Semester 2016 Course prefix and number: MAIN 220 Course title: Mechatronics Credit hours: 3 Contact hours: (Lecture hours: 2 Lab hours: 2) Days and times the course meets: Tuesdays Catalog Description: Prerequisite: ELTC 206 with a grade of C or better, or ELTC 207 with a grade of C or better, or MAIN 222 with a grade of C or better. This course covers the process required for the planning and actual installation of industrial machinery. The course includes preventive maintenance and planning for in-plant operations. Instructor Information: Instructor name: Chris Miller Phone number to contact instructor: (309) 268-8855 Instructor e-mail address: Chris.Miller@heartland.edu Location of instructor’s office: WDC 1213 Hours and days of instructor’s office hours: M,T,W 1-3pm, Fri apt. Website: http://www.technology.heartland.edu/faculty/chrism/ Required Textbook: Stenerson, Jon. Industrial Automation and Process Control Upper Saddle River, NJ: Prentice Hall, 2003. Recommended: Online supplemental info will be announced Supplies: Multimeter Relationship to Academic Development Programs and Transfer: MAIN 220 was designed to meet the specific needs of an Associate of Applied Science degree and not necessarily as a transfer course, particularly in relation to the Illinois Articulation Initiative. This course may transfer to various institutions in a variety of ways. Please see an academic advisor for an explanation concerning transfer options. COURSE OBJECTIVES (Learning Outcomes) Outcomes 1. Demonstrate an understanding of proper safety used in an automation and control environment. 2. Demonstrate a knowledge and awareness of mechanical power, electrical power and fluid power concepts. 3. Create a preventative maintenance program for a simple automated process. 4. Research and present information relating to a machine installation and maintenance technology as it relates to the student’s field of study. 5. Describe how to install an automated electrical circuit. 6. Apply appropriate techniques to correctly measure mechanical, electrical and fluid systems using bench top testing devices. 7. Apply mechanical, electrical and fluid theories to the work environment. 8. Compose a list of troubleshooting techniques to determine best solution for an industrial process. General Education Outcomes Range of Assessment Methods Labs Exams/Quizzes Assignments Labs Written Project Assignments PS1 Labs Graded Lab Assignments Assignments Course/Lab Outline: 1. Move machinery using safe and effective procedures. 2. Select and use proper equipment to move / install and maintain machines. 3. Install new equipment in accordance with the manufacturer and engineering specifications. 4. Perform pre-production activities and verify machine start-up. 5. Apply preventive maintenance programs; keep preventive maintenance records. 6. Maintain machinery in accordance with design and safety standards 7. Modify existing machinery to meet in-plant and governmental needs and regulations. Course Policies: Method of Evaluation (Tests/Exams, Grading System): (To be determined by each instructor): E-learn Robot Assignments FMS Labs Project Midterm Final 40% 10% 5% 15% 10% 10% 10% Grades will be based on the following scale: 90 – 100% A 80 – 89% B 70 – 79% C 60 – 69% D Below 60% F Participation (or Attendance) Attendance will be taken for sake of monitoring when students were in lab. Incompletes An incomplete grade may be given to a student who, by the withdrawal date, can reasonably be expected to pass the course. Incompletes may be granted only when justified by extreme circumstances (e.g., serious illness, accident, death or serious illness in the immediate family). Incomplete grades are not given for such reasons as unjustified failure to appear for the final examination. A written agreement, outline the requirements to be met, must be signed by the instructor and the student. The agreed upon requirements must be completed no later than the end of the following semester (spring semester for incompletes granted during the fall, and the following fall for incompletes given during the spring and summer semesters). By the agreed upon date, the instructor will assign a grade or the incomplete will be changed to an ‘F’ if the requirements are not completed. Extra Credit No none. Missing an exam and assignments policy You must be present at all exams when they are assigned. I will not allow you to make up a test. Only if you have an exemption from me, confirmation by voice or email, prior to the exam will I consider allowing you to take it at a different time. REQUIRED WRITING AND READING: There will be a final project which will include a written section. The project will relate to an industrial maintenance and installation procedure. In addition students will be expected to read assigned selections from the textbook. All labs are to include descriptive comments within the write-up/answer section relating to each lab. Syllabi disclaimer Any changes will be posted and clearly communicated to students. Course Calendar: Please visit my website or Blackboard for specific dates and times for materials. 1. MAIN 220 Date Videos Week # 1-12-16 Spring 2016 Objectives Reading What is Mechatronics Course Set-up Chapter 1 Chapter 2 #1 Labs HW Pre Class Assessment Sign Safety Sheet Questions Ch1 p.18 PETS-II section 1-3 entire class overview Questions Ch 3 p.54 Questions Ch 2 p.35 Campus Safety Video Electrical Safety / Arc Flash Instructional Set-up Introduction to PLCs / Fundamentals of programming Chapter 3 1-19-16 #2 Ch 13 Eaton Industrial Hydraulics Proportional Valves Gain, dead band, dither, ramp 1-26-16 Fluid Power Chapter 11 #3 Fundamentals of Process Control Chapter 12 Fundamentals of Process Control Chapter 13? PETS-II Section 4 Electronic Circuit Configuration p.5-p.16 PETS-II Section 5 Open-Loop Velocity Lab with PLC Control p.17-30 Pets-II Section 6 Closed-Loop Proportional Valve p.31-37 Questions Ch 12 p.280 Questions ch 13 p. 304? Ch 14 Eaton Industrial Hydraulics Read a hysteresis curve 2-2-16 Motor Resistance Wye Delta Intro to industrial motors ch 5 ch 8 ho Questions Ch 9 p.153 Basic insulation testing ho #4 Motor Rotation meter Identifying Unmarked 9 Lead Troubleshooting electrical schematics ho Motor Rotation class guided How Real Electric Motors Work web Megger Lab Delta Identifying Unmarked 9 lead Wye Buying an energy efficient electric motor DOE ho ACME megger ho Reducing Power Factor Cost DOE ho TheoryMegger ho Understanding insulation resistance testing ho 2-9-16 VFD VFD Lab #5 VFD presentation summer 2015 ho SMC Trainer Part 1 2-16-16 Sensors Chapter 9 SMC Trainer Part 2 #6 Troubleshooting Chapter 16 Questions Ch 16 p.389 In class activity grafcet I/O wiring and advanced programming Chapter 7 Siemens STEP website PLC intro SMC Trainer Part 3 2-23-16 REVIEW #7 MIDTERM EXAM 3-02-16 #8 3-16-16 Roboguide Tutorial System Variables on a Fanuc Robot MATC #9 Tool Fames MATC User Frames MATC 3-23-16 How to Program a circle MATC Position Register MATC #10 3-30-16 Robots Chapter 10 Questions Ch 10 p.227 Fanuc Robot Unit 2 Pre-Test (Instructor Led Activity) Unit 3 Safety Unit 4 Robot System Elearning Robot Operations Fanuc Robot Unit 5 Power Up and Jogging Procedure 5-1 Turning On Robot Procedure 5-4 Displaying the Alarm Log p.70 Procedure 5-5 Recovering from an Overtravel Error p.74 Procedure 5-6 Recovering from a Hand Breakage p.76 Procedure 5-7 Chain Failure Detection Error Recovery p.78 Procedure 5-8 Jogging the Robot and other axes p.80 Procedure 5-9 Setting Up Axis Limits p.87 Procedure 5-10 Displaying the Version Identification Status p.88 Fanuc Robot Lab 2 Set Axis Limits p.95 Lab 3 Jog the robot in WORLD mode p.97 Elearning Robot Operations Lab 4 Alternating Between Quick /Full Menu p.99 Lab 5 Viewing the Version Identification p.100 Elearning Unit 6 Frame Set up Procedure 6-1 Setting Up Tool Frame Using the Three Point Method p.107 Procedure 6-2 Setting Up Tool Frame Using the Six Point Method p.112 Procedure 6-3 Setting Up Tool Frame Using the Direct Entry Method p.117 Procedure 6-4 Using the Jog Menu p.121 Procedure 6-5 Selecting a Tool Frame p.122 Procedure 6-6 Setting Up the User Frame Using the Three Point Method p.132 Procedure 6-7 Setting Up the User Frame Using the Four Point Method p.138 Procedure 6-8 Setting Up the User Frame Using the Direct Entry Method p.145 Procedure 6-9 Selecting a User Frame p.148 Procedure 6-10 Setting Up the Jog Frame Using the Three Point Method p.152 Procedure 6-11 Setting Up the Jog Frame Using the Direct Entry Method p.157 #11 4-06-16 Fanuc Robot Unit 7 Creating and Writing a Program Unit 8 Motion Instructions #12 Procedure 7-1 Change Wrist Orientation p.172 Procedure 7-2 Create a New Program p.181 Procedure 7-3 Adding Motion Instructions to a TP Program p.188 Procedure 7-4 EMERGENCY STOP p.190 Procedure 7-5 Recovery from EMERGENCY STOP p. 191 Procedure 7-6 HOLD and Recovery p.191 Procedure 7-7 Setting Up Test Cycle Conditions p.194 Procedure 7-8 Single Step Testing p.197 Procedure 7-9 Continuous Testing Using the Teach Pendent p. 201 Procedure 7-10 Continuous Testing Using the Operation Panel CYCLE START Button p. 203 Procedure 7-11 Running Production Using Standard Operator Panel (SOP) Cycle Start Procedure 8-1 Defining Default Motion Instructions p.229 Procedure 8-2 Displaying and Setting Position Registers p.235 4-13-16 #13 AET 3103 Robotics and Controls CALL programming EIU Fanuc Robot Unit 9 Copy and Editing Programs Unit 10 Program Instructions Unit 11 I/O Programming Instructions & Operation Procedure 9-1 Copying a program within SELECT menu p.246 Procedure 9-2 Deleting a Program p.247 Procedure 9-3 Modifying a Program p.250 Procedure 10-1 Displaying and Setting Registers p.275 Procedure 11-1 Setting Up Digital I/O p.310 Procedure 11-2 Setting Up Group I/O p.316 Procedure 11-3 Forcing Outputs p.322 Procedure 11-4 Simulating and Unsimulating Inputs p.323 4-20-16 Fanuc Robot Unit 12 Miscellaneous Instructions Unit 13 System Variables #14 Procedure 12-1 Displaying the Program Timer Screen p.341 Procedure 13-1 Displaying and Setting System Variables p.351 Lab 6 TOOL Frame Set Up p.125 Lab 7 Create a USER and JOG Frame p.163 Robot Operations Completed Elearning Handling Tool Lab 8 Create a Program p.208 Lab 9 Motion Instruction p.241 Elearning Handling Tool Lab 10 Optional Program p.242 Lab 11 Select / Modify and Execute a Program p. 261 Lab 12 Register Instructions p. 285 Lab 13 Modifying Programs using Branching Instructionsp.289 Lab 14 Calling Programs p.290 Lab 15 Input/Output p.337 Lab 16 Miscellaneous and Other TP Instructions p.345 Lab 17 System Variable $SHFTOV_ENB and $DMAURST p.353 Lab 18 System Variable $SCR_GRP[1] p.354 Elearning Handling Tool completed 4-27-16 #15 5-04-16 #16 Fanuc Robot Unit 14 Macro Commands Lab 19 MACRO Commands p.367 Procedure 14-1 Setting Up Macro Commands p.359 Procedure 14-2 Assigning a Macro to SOP p.362 Procedure 14-3 Assign Macro to USER key on teach Pendant p.363 Procedure 14-4 Assign Macro to a Digital Input p.363 Procedure 14-5 Assign Macro to a Manual Function Key p.364 Fanuc Robot Unit 15 Program Adjust Unit 16 Program & File Manipulation Lab 20 Program Adjust p.381 Lab 21 Program and File Manipulation p.417 Procedure 15-1 Adjusting Programs During Program or Production Run Procedure 16-1 Using the Memory Card Interface p.384 Procedure 16-2 Setting the Default Device p.386 Procedure 16-3 Formatting a Memory Card from the File Menu p.391 Procedure 16-4 File Backup p.392 Procedure 16-5 Backing Up System and Program Files p.397 Procedure 16-6 Generating a Directory of Files p.397 Procedure 16-7 Deleting a Program from the SELECT Menu p.402 Procedure 16-8 Loading Files Using the FILE Menu p.404 Procedure 16-9 Loading a Program p.407 Procedure 16.10 Backing up a Controller as Images p.410 Procedure 16-11 Restoring Controller Images p.413 Project 5-11-16 #17 Project Due FINAL Subject to change all updates will be clearly defined prior to implementation. Industrial automation jon stenerson Fanuc Robotics System R-J3 Series Training Manual Fanuc Robot Training Elearning Web Training Eaton Industrial Hydraulics My polices: Spring 2016 Maintenance 220 Mechatronics To avoid confusion and problems for all of us, this is a supplemental policies sheet used in conjunction with the syllabus. 20% of your grade comes from tests. You must be present at all exams. I will not allow you to make up a test. Only if you have an exemption from me, confirmation by voice or email, prior to the exam will I consider allowing you to take it at a different time. Midterm = 10% Final = 10% 10% of your grade will come from assignments and reading / activity assessments. Assignments must be turned in on the date due. Unless otherwise stated the homework assignment will be due the following week it was assigned. I will not accept late work. Assignments =10% The following must be done in order for the assignment to be accepted: o No torn up paper, no spiral paper o Must be completed in either pencil, or black, blue ink. o It must be legible: readability, grammatically, and numerically professionally done o In upper right hand side the following must appear Name Date assignment is due Chapter and question numbers o You must show every step in your solution of the problem. If there is no work shown the entire assignment will not be counted. 5% of your grade will come from FMS 200 Functional Analysis, Start-Up and Block Analysis Activities, Electrical Analysis and Pneumatic Analysis. Each section must be completed and submitted in a presentable in a 3 ring binder form. We will discuss the specifics throughout the course. Late portions will have 25% marked off up to 1 week late. After that I will not accept it. The following must be done in order for the assignment to be accepted: o Must be electronically created. o Readability, grammatically, and numerically correct o Diagrams must be clearly labeled o You must show every step in your solution of the problem. If there is no work shown the entire assignment will not be counted. 40% of your grade will come from Elearning training. This a complete pass / fail opportunity. You must be successfully pass the Elearn Robot Operations prior to actually being able to use the robot. You will have three attempts to pass each Elearning training operation. To receive the full points both modules must successfully be done. Completed E-learn GE Fanuc Robots operation from GE’s website and obtained successful completion certificate ________________ signature _______________ date (Must be verified by Fanuc for 5%) Completed E-Learn GE Fanuc Handling Tool operation from GE’s website and obtained successful completion certificate ________________ signature _______________ date (Must be verified by Fanuc for 5%) Robot Operations online ____________ out of 500 points 10% Handling Tool and Operations __________ out of 700 points 10% Handling Pro _____________ out of 100 points 10% 15% of your grade will come from labs. Labs must be turned in on the due date, typically the week after in which it was assigned. No lab will be allowed after taking the exam in which it was used to prepare for. If you cannot complete the lab during in class time, the lab will be open for open lab time to complete. Fanuc Programing Procedures=5% (spot check for completion) Fanuc Robot Labs =5% (spot check for completion) PLC / Sensors Labs =5% graded activities The following must be done in order for the assignment to be accepted: o Lab clean up. You are responsible for lab clean up and returning of equipment. If you do not put equipment away and more importantly the components correctly away you will not get credit for that lab. o Your name must be included on the program you are submitting. o o o Your name and date shall be on every lab. If the lab is using ladder logic it must be a print of the ladder logic from PLC software. You must follow the guidelines provided for the activity being completed. 10% of your grade will come from a final project. If it is not turned in according to the directions and or not submitted on the final due date it will not be accepted. Please see final project info on website for the specific information. Midterm Withdrawal Students are expected to attend class during the regularly scheduled times and participate in both the lectures and labs. It is the responsibility of the student to keep up with all posted materials. Meaningful and timely participation is required for success in this course. Any student who is not participating in the course and making reasonable attempts to successfully complete all course activities (labs, exams, homework, quizzes, usw.) will be withdrawn from the course at midterm. All answers must be clearly denoted if in doubt it will be wrong! Grades will be based on the following scale: 100 – 90% A 89 – 80% B 79 – 70% C 69 – 60% D Below 60% F Name: _____________________________________ Date:__________________________ Elearning Robot Operations Elearning Handling Tool Lab activities/ programming the robot through Fanuc Robotics Training Manual a. b. c. d. e. f. g. h. i. j. k. l. m. n. o. p. q. r. s. t. u. v. w. x. y. z. aa. bb. cc. dd. ee. ff. gg. hh. ii. jj. kk. ll. mm. nn. Procedure 5-1 Turning On Robot Procedure 5-4 Displaying the Alarm Log p.70 Procedure 5-5 Recovering from an Overtravel Error p.74 Procedure 5-6 Recovering from a Hand Breakage p.76 Procedure 5-7 Chain Failure Detection Error Recovery p.78 Procedure 5-8 Jogging the Robot and other axes p.80 Procedure 5-9 Setting Up Axis Limits p.87 Procedure 5-10 Displaying the Version Identification Status p.88 Procedure 6-1 Setting Up Tool Frame Using the Three Point Method p.107 Procedure 6-2 Setting Up Tool Frame Using the Six Point Method p.112 Procedure 6-3 Setting Up Tool Frame Using the Direct Entry Method p.117 Procedure 6-4 Using the Jog Menu p.121 Procedure 6-5 Selecting a Tool Frame p.122 Procedure 6-6 Setting Up the User Frame Using the Three Point Method p.132 Procedure 6-7 Setting Up the User Frame Using the Four Point Method p.138 Procedure 6-8 Setting Up the User Frame Using the Direct Entry Method p.145 Procedure 6-9 Selecting a User Frame p.148 Procedure 6-10 Setting Up the Jog Frame Using the Three Point Method p.152 Procedure 6-11 Setting Up the Jog Frame Using the Direct Entry Method p.157 Procedure 7-1 Change Wrist Orientation p.172 Procedure 7-2 Create a New Program p.181 Procedure 7-3 Adding Motion Instructions to a TP Program p.188 Procedure 7-4 EMERGENCY STOP p.190 Procedure 7-5 Recovery from EMERGENCY STOP p. 191 Procedure 7-6 HOLD and Recovery p.191 Procedure 7-7 Setting Up Test Cycle Conditions p.194 Procedure 7-8 Single Step Testing p.197 Procedure 7-9 Continuous Testing Using the Teach Pendent p. 201 Procedure 7-10 Continuous Testing Using the Operation Panel CYCLE START Button p. 203 Procedure 7-11 Running Production Using Standard Operator Panel (SOP) Cycle Start Procedure 8-1 Defining Default Motion Instructions p.229 Procedure 8-2 Displaying and Setting Position Registers p.235 Procedure 9-1 Copying a program within SELECT menu p.246 Procedure 9-2 Deleting a Program p.247 Procedure 9-3 Modifying a Program p.250 Procedure 10-1 Displaying and Setting Registers p.275 Procedure 11-1 Setting Up Digital I/O p.310 Procedure 11-2 Setting Up Group I/O p.316 Procedure 11-3 Forcing Outputs p.322 Procedure 11-4 Simulating and Unsimulating Inputs p.323 oo. pp. qq. rr. ss. tt. uu. vv. ww. xx. yy. zz. aaa. bbb. ccc. ddd. eee. fff. ggg. Procedure 12-1 Displaying the Program Timer Screen p.341 Procedure 13-1 Displaying and Setting System Variables p.351 Procedure 14-1 Setting Up Macro Commands p.359 Procedure 14-2 Assigning a Macro to SOP p.362 Procedure 14-3 Assign Macro to USER key on teach Pendant p.363 Procedure 14-4 Assign Macro to a Digital Input p.363 Procedure 14-5 Assign Macro to a Manual Function Key p.364 Procedure 15-1 Adjusting Programs During Program or Production Run Procedure 16-1 Using the Memory Card Interface p.384 Procedure 16-2 Setting the Default Device p.386 Procedure 16-3 Formatting a Memory Card from the File Menu p.391 Procedure 16-4 File Backup p.392 Procedure 16-5 Backing Up System and Program Files p.397 Procedure 16-6 Generating a Directory of Files p.397 Procedure 16-7 Deleting a Program from the SELECT Menu p.402 Procedure 16-8 Loading Files Using the FILE Menu p.404 Procedure 16-9 Loading a Program p.407 Procedure 16.10 Backing up a Controller as Images p.410 Procedure 16-11 Restoring Controller Images p.413 Robot Labs A. Lab 1 Power Up and Jog the Robot in JOINT p.93 5 B. Lab 2 Set Axis Limits p.95 5 C. Lab 3 Jog the robot in WORLD mode p.97 5 D. Lab 4 Alternating Between Quick /Full Menu p.99 5 E. Lab 5 Viewing the Version Identification p.100 5 F. Lab 6 TOOL Frame Set Up p.125 6 G. Lab 7 Create a USER and JOG Frame p.163 6 H. Lab 8 Create a Program p.208 7 I. Lab 9 Motion Instruction p.241 8 J. Lab 10 Optional Program p.242 8 K. Lab 11 Select / Modify and Execute a Program p. 261 9 L. Lab 12 Register Instructions p. 285 9 M. Lab 13 Modifying Programs using Branching Instructionsp.289 10 N. Lab 14 Calling Programs p.290 10 O. Lab 15 Input/Output p.337 11 P. Lab 16 Miscellaneous and Other TP Instructions p.345 12 Q. Lab 17 System Variable $SHFTOV_ENB and $DMAURST p.353 13 R. Lab 18 System Variable $SCR_GRP[1] p.354 13 S. Lab 19 MACRO Commands p.367 14 T. Lab 20 Program Adjust p.381 15 U. Lab 21 Program and File Manipulation p.417 16 FMS 200 Troubleshooting PLC / Sensors Labs Project