Week10PPmetals

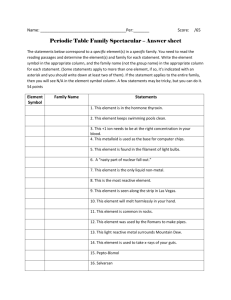

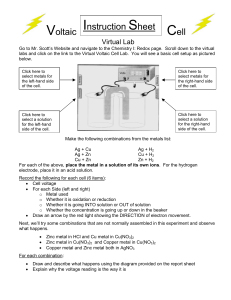

advertisement

Metals and the Environment EAEE E4001 Nickolas J. Themelis 1 METALS AND CIVILIZATION From the dawn of civilization, metals have been associated with economic development, prosperity, and even art: “Native” gold, silver, and copper alloys were the first form of currency and the second form of art (after stone carvings). The Bronze Age and the Iron Age were named after metals. METALS IN THE 21ST CENTURY Many people think that today everything is done by computers. But the computers are made of metal. Also, all commercial and industrial buildings. And all means of transportation. And all generators of electricity and motors. And the conveyors of 99.99% of the electricity used by humanity (fiber optics do the rest). In fact, the skeleton, muscles, and skin of modern civilization are made of metals. THE PRINCIPAL METALS AND THEIR GLOBAL PRODUCTION IN 2000 in million tons Iron (Fe, 55.85) and steel (Fe+C/alloys): 833 Aluminum (Al, 26.98): 23.9 Copper (Cu, 63.55): 12.9 Zinc (Zn, 65.39): 8 Manganese (Mn, 54.94): 7.45 Lead (Pb, 207.2): 2.98 Nickel (Ni, 58.69): 1.23 Magnesium (Mg, 24.31): .284 Gold (Au, 196.97): .0025 Silver (Ag 107.87): .0179 (molecular weights g/mol) source: USGS Annual consumption of copper during the 20th century Copper is principally used in electrical and water conduits Its per capita use is a good measure of the material standard of living in a nation • 10 kg/capita for the highly developed nations • 0.6 kg/capita in China • 0.2 kg/capita in India • More used in 20th century than in all millennia Ore RESERVES are not infinite: Effect of ore type on energy needed per ton of production (H.H. Kellogg) Energy (and CO2) savings from metal recycling Estimated global anthropogenic emissions in tons/year (after Nriagu &Pacyna 1998) As Cd Cr Cu Hg Ni Pb Zn To atmosphere: 18800 7600 30500 35400 3600 55700 332400 131900 75% % Contribution of global metal industry: 80% 50% 75% 1% 35% 10% 80% To aquatic systems: 4100 9400 142000 112000 4600 113000 138000 226000 10% % Contribution of global metal industry: 10% 20% 10% 2% 20% 5% 10% Advantages of “continuous” over “batch” smelting processes: Copper production from virgin or recycled materials (Noranda process) • Use of heat from sulfur combustion • Production of sulfuric acid (instead of SO2 emissions) • Can smelt any kind of copper scrap Off-gases Feeding Port Burner Slag Matte concentrates Slag exit hole Tuyeres air+oxygen Copper exit hole APPLICATION OF METAL PRODUCTION TECHNOLOGIES TO 21th CENTURY PROBLEMS Technology Applied geophysics For humanity Mining Exploration for minerals and fuels Extraction of minerals For Earth Hydrometallurgy Metal production and refining Pyrometallurgy Metal production and refining Environmental assessment and remediation Brownfield/greenfield Mine rehabilitation Landfill engineering Constructed wetlands Water/soil decontamination Metal recovery from wastes Materials/energy from wastes Vitrification Earth and Environmental Engineering : A new discipline for materials and the environment Intelligent processing of combustible solid wastes for energy and metal resource recovery at Waste-to-Energy plant at Rochester, MA (developed by EAC) INDUSTRIAL ECOLOGY LESSONS FOR METAL PRODUCTION AND USE IN 21ST CENTURY Production and use of metals and all other materials must take into account the needs of both Humanity and the Earth. INDUSTRIAL ECOLOGY LESSONS FOR METAL PRODUCTION AND USE IN 21ST CENTURY Metal extraction is one of the most Earth-intrusive industrial activities. Engineers need to be fully cognizant of upstream (raw materials) and downstream (products) effects of their activities. INDUSTRIAL ECOLOGY LESSONS FOR METAL PRODUCTION AND USE IN 21ST CENTURY Dispersive uses of metals must be phased out and post-use material/energy recovery increase: Advantage for processes that can use as feedstock both “virgin” and recycled materials, such as scrap and waste streams. World steel production from ore (pig iron) and recycled steel