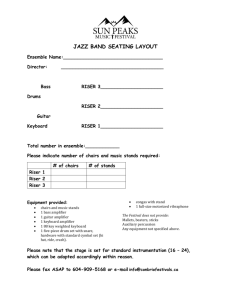

General Rules

advertisement

Petroleum Engineering 406 Floating Drilling Lesson 10 The Drilling Riser 1 Lesson 10A - The Drilling Riser Riser Components Riser Tensioning Fatigue Kill/Choke Lines Inspection & Maintenance Reentry 2 RISER TENSION SLIP JOINT INNER BARREL KILL AND CHOICE LINES SLIP JOINT OUTER BARREL UPPER BALL JOINT RISER JOINTS LOWER BALL JOINT BOP Mudline Riser system for a floating drilling rig 3 Marine riser = drilling riser, get returns to surface, well control, communications link Integral Marine Riser Joints 4 Choke and kill lines are integral with the marine riser , flanged connections; clamp, etc Integral Marine Riser Connector Flanged connection - 6 bolts NOTE: Choke and Kill Lines O-ring type seals - inspect when running 5 Integral Marine Riser Connector 6 Marine Riser Flexible Joint 7 Flexible joint, binding from high tensile forces, inject lubricant, up to 1,500,000 lbf! FLEXIBLE JOINT TELESCOPIC JOINT MARINE RISER DIVERTER ASSEMBLY RISER TENSIONING LINES KILL AND CHOKE LINES Upper Section Marine Riser System. 8 Mud returns L.P. Annular Control valve Vent line A diverter system. 9 Re-directs flow from rig floor to blooey line (10”+), downwind, do not shut in, erosion -10E8 Figure 6-6. Vertical steel loops used for kill / choke line transition around the ball joint. 10 The Drilling Riser MEAN WATER LEVEL RISER ELEMENT Schematic diagram of riser with imposed forces 11 Optimum riser tension to minimize damage to riser and wear-and-tear on tensioners, sag Maximum stress Mean tension Minimum stress Applied tension in riser, kips 12 Tension in riser must be not too low and not too high. Set at 118 kips - will fluctuate 100-136 kips ~ 15% Riser Considerations: Riser Metallurgy is very important. Correct heat treatment is essential. 80,000 psi min. yield strength and good toughness is preferred. Preheating, welding & normalizing after welding is critical for riser integrity & long life. 13 Riser Considerations: No Field Welding on Riser! Fatigue of riser cannot be measured prior to some indication of failure. Routine inspection required. 14 Riser Considerations: Fatigue is an embrittlement of the metal. It often starts in the vicinity of welds or other places of high stress concentration. Fatigue is caused by cyclic loading. 15 Riser Inspection: Visual Inspection of the riser should occur every time the riser is run. Check all the seals Check all the sealing areas 16 Riser Inspection: A complete inspection should be made annually. Dyes: Will detect cracks. To use dyes, paint must be removed. Magnetic Particle Inspection: Sand blast areas around welds prior to magnetic particle inspection. 17 Riser Inspection: Ultra-Sonic Inspection: May detect cracks below the surface. This test is run inside pipe. Paint removal is not necessary. X-Ray Inspection: Is for cracks inside the metal. It may miss surface cracks. *No one technique will find all the cracks. 18 Riser Instrumentation: Heavy Gauge: Pointer attached to guide line moving in front of graduated board. Riser Angle Indicator (at ball joint): 2 x 2 y 1/ 2 tan 1 tan 2 x tan 2 y 1/ 2 19 Riser Instrumentation: Accurate Positioning System: For detecting and monitoring vessel position. 20 Ball Joint: A Ball Joint Angle > 4 degrees is an indication that something is wrong! Vessel is offset Riser tension is inadequate 21 Ball Joint: Must decrease ball joint angle before operations are resumed. Remedial Action: Decrease Offset Increase Riser Tension 22 Vessel to Seafloor Guidance System Guidelines are used for guiding equipment from the vessel to the seafloor. Selection and care of guidelines is critical. 23 Vessel to Seafloor Guidance System Guidelines should not be tensioned beyond 1/3 of breaking capacity But…inadequate tension is the most common cause of failure in guidelines 24 Vessel to Seafloor Guidance System Tension should be maximum when landing the BOP stack, or when landing the riser onto the stack. When the guidelines are not being used to run equipment, tension may be slacked off to ~ twice the weight of the line in seawater. 25 Table 6-1. Recommendations for Conventionally Used Guidelines As water depth increases, larger diameter guidelines must be used. Higher tensioning is required. Don’t forget to limit tension to < 1/3 of breaking strength. 26