5679531e3b0ac

advertisement

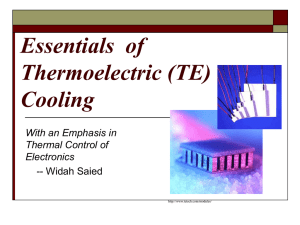

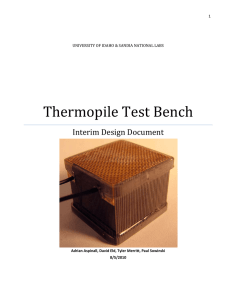

1) Title of Tech offer: Wearable Thermoelectric Micro-cooler 2) Abstract (Summary of Tech offer) A team at Republic Polytechnic has successfully fabricated prototype thermoelectric (TE) micro-coolers using state-of-the-art Bi2Te3 based thin films suitable for integration in electronic and optoelectronic components and devices. The fabricated microcooler exhibits desirable TE properties and good electrical reliability. Freestanding TE micro-devices of any desired shape and dimensions can be fabricated using a relatively simple process protocol by sputter deposition and microfabrication processing methods, which enables large-area coating to be achieved with consistent results and at low processing temperatures. The TE modules are capable of converting electric energy into heat and vice versa directly. These devices are suitable for integration into existing sportswear to provide more comfortable garments for use in extreme weather conditions and environments, thereby improving outdoor performance and reducing heat stroke. 3) Technology Overview (A brief summary or description of the invention - What is the problem solved by this technology? Who is going to buy this technology? How is this IP addressing a need/problem in the marketplace?) Many different devices have been developed to create the preferred environmental conditions, particularly maintaining the body temperature. Devices that were developed earlier include mechanical heating, air conditioning, and specialised clothing that circulates cooling fluids. These devices are often bulky, heavy, and can bring more discomfort to the person in performing his/her activity efficiently. More recently, thermoelectric devices incorporated into environmental suits to circulate cool air have been reported, but they provide lower cooling efficiency as they are designed to cool the entire suit and therefore consuming more power. Thus, an efficient integrated wearable cooling system that involves localised cooling and lightweight materials is required. 4) Technology Features and Specifications (What does the technology comprise of? E.g. Video camera, software algorithm) (i) Thermoelectric solid state coolers are compact, efficient and they can fit the size of semiconductor chips easily. Thermoelectric cooling is an attractive way for spot and portable temperature control. (ii) Growth of thermoelectric multilayers using a sputtering deposition method (iii) Microfabrication of TE films using a standard silicon process flow (iv) Easy integration (v) Faster switching time (vi) Better performance (vii) Good reliability (viii) Environmental friendly The key features of the devices are: • No moving parts, so little maintenance required • Devices can exceed 150,000 hours of steady state operation • Contain no chlorofluorocarbons or other materials that may require periodic replenishment • The direction of heat-pumping in a TE system is fully reversible. Changing the polarity of the DC power supply causes heat to be pumped in the opposite direction where a cooler can then become a heater • Precise temperature control to within 0.1ºC can be maintained • Can function in severe and sensitive environmental conditions, or in applications where conventional refrigeration units cannot be used. 5) Potential Applications (In which industry can this technology be employed? What are the products that can be marketed based on this technology?) The technology can be applied in the areas of: • Microelectronic and Optoelectronic Devices (Spot coolers) • Sports wear, uniforms • Logistics • Healthcare • Aerospace and Defence • Energy and environment Depending on their working modes, TE applications can be classified into three categories: coolers (or heaters); power generators; or thermal energy sensors. TE coolers are used in cases where the cooling system design criteria call for high reliability, small size, low weight, intrinsic safety and precise temperature control. 6) Market Trends and Opportunities (What is the approximate market size for this technology? What makes this IP attractive to the market?) The global market for Electronic Thermal Management (ETM) is forecast to reach $10.1 billion by 2017. The market for thermoelectric energy harvesters is projected to reach $875 million by 2023. Fabrication of flexible free-standing thermoelectric structures on a plastic substrate opens a new area of innovation and applications namely, portable medical devices, flexible electronics and wearable fabrics. The fabrication method and process parameters would establish a long term applications of processing method and technique. The use of multi or hybrid layer approach for depositing the thermoelectric films on a suitable seed layer help to achieve a lower electrical resistivity or a higher figure of merit (cooling efficiency) of TE films. 7) Customer Benefits (How is this an improvement over the "State of the Art?" What is the Value Proposition?) The unique features of the present invention are the following: (i) (ii) (iii) (iv) (iv) (v) Free-standing TE cooler on a metal coated flexible substrate Process protocol for sputtering fabrication process for a metal coated plastic wafer Simple fabrication process using sputtering and shadow mask process Large area coating process Energy efficient operation of flexible TE cooler using designed power control circuit Integrated, energy efficient and flexible TE cooler on a wearable fabric The key advantages of the present invention would be the following: (i) (ii) Fabrication using either clean room or non-clean room facilities Easy integration to outdoor garments/sports wear Fig 1 Thermoelectric Peltier Model N P Au Electrode Plastic Film Substrate Fig 2 Thermoelectric Flexible Cooler Figure 3 Wearable Thermoelectric Micro-cooler