Photovoltaic Driven Dual Purpose Thermoelectric ... for Rural India

advertisement

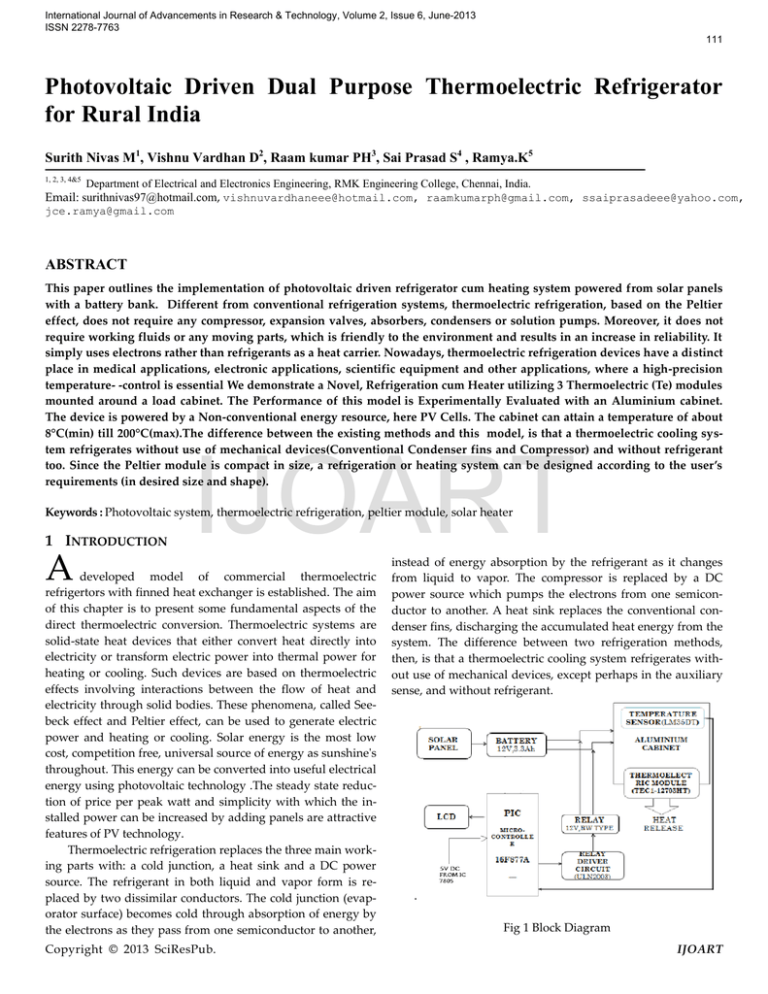

International Journal of Advancements in Research & Technology, Volume 2, Issue 6, June-2013 ISSN 2278-7763 111 Photovoltaic Driven Dual Purpose Thermoelectric Refrigerator for Rural India Surith Nivas M1, Vishnu Vardhan D2, Raam kumar PH3, Sai Prasad S4 , Ramya.K5 1, 2, 3, 4&5 Department of Electrical and Electronics Engineering, RMK Engineering College, Chennai, India. Email: surithnivas97@hotmail.com, vishnuvardhaneee@hotmail.com, raamkumarph@gmail.com, ssaiprasadeee@yahoo.com, jce.ramya@gmail.com ABSTRACT This paper outlines the implementation of photovoltaic driven refrigerator cum heating system powered from solar panels with a battery bank. Different from conventional refrigeration systems, thermoelectric refrigeration, based on the Peltier effect, does not require any compressor, expansion valves, absorbers, condensers or solution pumps. Moreover, it does not require working fluids or any moving parts, which is friendly to the environment and results in an increase in reliability. It simply uses electrons rather than refrigerants as a heat carrier. Nowadays, thermoelectric refrigeration devices have a distinct place in medical applications, electronic applications, scientific equipment and other applications, where a high-precision temperature- -control is essential We demonstrate a Novel, Refrigeration cum Heater utilizing 3 Thermoelectric (Te) modules mounted around a load cabinet. The Performance of this model is Experimentally Evaluated with an Aluminium cabinet. The device is powered by a Non-conventional energy resource, here PV Cells. The cabinet can attain a temperature of about 8°C(min) till 200°C(max).The difference between the existing methods and this model, is that a thermoelectric cooling system refrigerates without use of mechanical devices(Conventional Condenser fins and Compressor) and without refrigerant too. Since the Peltier module is compact in size, a refrigeration or heating system can be designed according to the user’s requirements (in desired size and shape). IJOART Keywords : Photovoltaic system, thermoelectric refrigeration, peltier module, solar heater 1 INTRODUCTION A developed model of commercial thermoelectric refrigertors with finned heat exchanger is established. The aim of this chapter is to present some fundamental aspects of the direct thermoelectric conversion. Thermoelectric systems are solid-state heat devices that either convert heat directly into electricity or transform electric power into thermal power for heating or cooling. Such devices are based on thermoelectric effects involving interactions between the flow of heat and electricity through solid bodies. These phenomena, called Seebeck effect and Peltier effect, can be used to generate electric power and heating or cooling. Solar energy is the most low cost, competition free, universal source of energy as sunshine's throughout. This energy can be converted into useful electrical energy using photovoltaic technology .The steady state reduction of price per peak watt and simplicity with which the installed power can be increased by adding panels are attractive features of PV technology. Thermoelectric refrigeration replaces the three main working parts with: a cold junction, a heat sink and a DC power source. The refrigerant in both liquid and vapor form is replaced by two dissimilar conductors. The cold junction (evaporator surface) becomes cold through absorption of energy by the electrons as they pass from one semiconductor to another, Copyright © 2013 SciResPub. instead of energy absorption by the refrigerant as it changes from liquid to vapor. The compressor is replaced by a DC power source which pumps the electrons from one semiconductor to another. A heat sink replaces the conventional condenser fins, discharging the accumulated heat energy from the system. The difference between two refrigeration methods, then, is that a thermoelectric cooling system refrigerates without use of mechanical devices, except perhaps in the auxiliary sense, and without refrigerant. . Fig 1 Block Diagram IJOART International Journal of Advancements in Research & Technology, Volume 2, Issue 6, June-2013 ISSN 2278-7763 Hardware Requirements: Thermoelectric module (Tec1-12703HT) PIC Microcontroller (16F877A) Temperature sensor (LM35Dz) Power storage battery (12v,7.2Ah) Solar panel (12v,5w,750mA) Relay (10A,24VDC) Relay driver (ULN2003) LCD 112 called "carriers" and they are the agents that move the heat energy from the cold to the hot junction. Heat absorbed at the cold junction is pumped to the hot junction at a rate proportional to carrier current passing through the circuit and the number of couple. Good thermoelectric semiconductor materials such as bismuth telluride greatly impede conventional heat conduction from hot to cold areas, yet provide an easy flow for the carriers. In addition, these materials have carriers with a capacity for transferring more heat. 2 PRINCIPLE OF SOLAR POWER GENERATION The principle of power generation behind the solar cells consists of the utilization of the photovoltaic effect of semiconductors. When such a cell is exposed to light, electron-hole pairs are generated in proportion to the intensity of the light. Solar cells are made by bonding together p-type and n-type semiconductors. The negatively charged electrons move to the ntype semiconductor while the positively charged holes move to the p-type semiconductor. They collect at both electrodes to form a potential. When the two electrodes are connected by a wire, a current flows and the electric power thus generated can be transferred to an outside application. Fig 3 Dimensions of Peltier module Sno 1. Item Input voltage max. Symbol Vmax Parameter 15.4V 2. Max. current Imax 3.3A 3. Max. heating temperature Tmax 200°C 4. Min. cooling temperature Tmin 6°C IJOART Fig 4 Specifications Of Peltier Module The high performance of the thermoelectric coolers, produced allows us to increase the rate of cooling and reach a larger temperature difference in relation to the environment. Thermoelectric coolers are optimized for source voltage 12V and perform high cooling as well heating at low power consumption 4 PIC MICRO CONTROLLER (16F877A) Fig 2 Principle Of PV Cell PIC microcontroller is used to monitor heating and cooling inside the cabinet. It also controls the relay driver to change the mode(Heating mode or Cooling mode). 3 THERMOELECTRIC MODULE Heat absorbed at the cold junction is pumped to the hot junction at a rate proportional to carrier current passing through the circuit and the number of couple. The semiconductor materials are N and P type, and are so named because either they have more electrons than necessary to complete a perfect molecular lattice structure (N-type) or not enough electrons to complete a lattice structure (P-type). The extra electrons in the N-type material and the holes left in the P-type material are Copyright © 2013 SciResPub. Fig 5 Crystal Oscillator Circuit IJOART International Journal of Advancements in Research & Technology, Volume 2, Issue 6, June-2013 ISSN 2278-7763 The above circuit is the crystal oscillator that supplies frequency to trigger the logic gates in microcontroller. The microcontroller we use here has only 35 single-word instructions to learn .All single-cycle instructions except for program branches, which are two-cycle. Operating speed: DC – 20 MHz clock input DC 200ns instruction cycle. It has 10-bit, up to 8-channel Analog-to-Digital Converter (A/D). it has Analog Comparator module with - Two analog comparators Programmable onchip voltage reference (VREF) module Programmable input multiplexing from device inputs and internal voltage reference, Comparator outputs are externally accessible. Special features of this include 100,000 erase/write cycle Enhanced Flash program memory typical, 1,000,000 erase/write cycle Data EPROM memory typical, Data EEPROM Retention > 40 years, Self-reprogrammable under software control, In-Circuit Serial Programming™ (ICSP™) via two pins, Single-supply 5V In-Circuit Serial Programmingcomplete cycle, otherwise conduction will overlap. It also has CMOS technologies that includes following features of Low-power, high-speed Flash/EEPROM technology, Fully static design, Wide operating voltage range (2.0V to 5.5V), Commercial and Industrial temperature ranges, Low-power consumption. 113 ture range, while the LM35C is rated for a −40° to +110°C range (−10° with improved accuracy). The LM35 series is available packaged in hermetic TO-46 transistor packages, while the LM35C, LM35CA, and LM35D are also available in the plastic TO-92 transistor package. The LM35D is also available in an 8-lead surface mount small outline package and a plastic TO-220 package. 6 RELAY (10A, 24VDC) Here Relay is used to reverse the supply to change the mode i.e. to switch form cooling processes to heating vice versa. RW Series Relay covers switching capacity by 10A in spite of miniature size to comply with user’s wide selection. RWH is approved C-UL & TÜV safety standard. The employment of suitable plastic materials is applied under high temperature condition and various chemical solutions. Complete protective construction is designed form dust and soldering flux. If required, plastic sealed type is available for washing procedure. 12A at 120VAC for RW & 12A at 240VAC for RWH are UL approved. It is used for Domestic Appliances, Office Machines, Audio Equipment, Coffee-Pots, Control units, etc. 5 LM35 PRECISION CENTIGRADE TEMPERATURE SENSORS IJOART In this system the temperature prevailing inside the aluminium cabinet is measured using LM35DZ sensor whose output is given to microcontroller to interpret it into Celsius values. Its general description includes the LM35 series are precision integrated-circuit temperature sensors, whose output voltage is linearly proportional to the Celsius (Centigrade) temperature. The LM35 thus has an advantage over linear temperature sensors calibrated in ° Kelvin, as the user is not required to subtract a large constant voltage from its output to obtain convenient Centigrade scaling. The LM35 does not require any external calibration or trimming to provide typical accuracies of ±1⁄4°C at room temperature and ±3⁄4°C over a full −55 to +150°C temperature range. Low cost is assured by trimming and calibration at the wafer level. The LM35’s low output impedance, linear output, and precise inherent calibration make interfacing to readout or control circuitry especially easy. It can be used with single power supplies, or with plus and minus supplies. As it draws only 60 μA from its supply, it has very low self-heating, less than 0.1°C in still air. Fig 6 LM35DZ circuit diagram The LM35 is rated to operate over a −55° to +150°C temperaCopyright © 2013 SciResPub. Fig 7 Relay Circuit Diagram 7 RELAY DRIVER Here relay driver is used to drive the relay by providing 0V to switch on relay with 5V input from micro controller and vice versa. The ULN2003 is a monolithic high voltage and high current Darlington transistor arrays. It consists of seven NPN Darlington pairs that features high-voltage outputs with common-cathode clamp diode for switching inductive loads. The collector-current rating of a single Darlington pair is 500mA. The Darlington pairs may be paralleled for higher current capability. Applications include relay drivers, hammer drivers, lamp drivers, display drivers(LED gas discharge),line drivers, and logic buffers. The ULN2003 has a 2.7kW series base resistor for each Darlington pair for operation directly with TTL or 5V CMOS devices. IJOART International Journal of Advancements in Research & Technology, Volume 2, Issue 6, June-2013 ISSN 2278-7763 114 Fig 8 Circuit Of Relay Driver ULN2003 8 LCD DISPLAY A liquid crystal display (commonly abbreviated LCD) is a thin, flat display device made up of any number of color or monochrome pixels arrayed in front of a light source or reflector. Fig 10 Circuit Diagram which monitors cooling and heating of the cabinet. Temperature sensor-LM35 series are precision integrated-circuit temperature sensors, whose output voltage is linearly proportional to the Celsius (Centigrade) temperature is kept inside the cabinet, whose output is given to PIC microcontroller which is programmed to interpret the voltage into Centigrade temperature values displayed in the LCD. In the cooling mode, PIC microcontroller allows power to the module till the temperature reaches minimum temperature and it maintains the same(once the temperature rises from the minimum temperature it restores the supply). For heating process, the supply given to the modules are reversed with the help of relay. IJOART Fig 9 Interfacing Lcd With Pic 16f877a It is often utilized in battery-powered electronic devices because it uses very small amounts of electric power. In this system LCD is used to display the current temperature values in °C along with indication whether system is in cooling mode or heating mode. It receives input regarding this information from the micro controller. 9 WORKING OF THE MODEL The source for our refrigeration cum heater system is renewable energy resource, here PV cells, are used. The power from the solar panel is given to two batteries (12V,7.25A). From batteries the power is delivered to peltier modules(3 nos) connected in parallel each attached to their respective heat sinks. Once the module gets the supply, it starts functioning (either cooling or heating according to its respective mode). The battery also supplies DC fan +fin (Heat Sink). PIC Microcontroller receives 5V from the A.C power source i.e through Step down transformer (230V to 12V), Copyright © 2013 SciResPub. Fig 11 Arial View Of The Model Once the terminals are reversed, the heating process starts. During heating, PIC microcontroller allows power to the module till the temperature reaches maximum point and it maintains the same (once the temperature falls below the maximum point the supply is restored) such that the temperature is maintained inside the cabinet. IJOART International Journal of Advancements in Research & Technology, Volume 2, Issue 6, June-2013 ISSN 2278-7763 115 Table 1: Comparison Between Existing Heator And Proposed Model Existing system : Fig 12 Performance Analyses Between Existing And Thermoelectric Model (cooling Graph) The above graph depicts the plot of time in minutes and load temperature in degree Celsius for thermoelectric model and existing domestic model. From the graph, it is clear that thermoelectric model attains the minimum temperature about 8°C in 40 minutes and maintains the same, where as the existing model takes 1hour to attain the same. Further the thermoelectric model maintains 8°C for nearly 5hours and then it starts decreasing as shown. where as in existing model negative temperature is achieved after 4 hours 10 minutes of time. This is the only disadvantage of the thermoelectric model in which the time taken to freeze is more. heater Thermoelectric heater : Cannot be operated during power outages. Can be operated during power outages as power is given from PV cells. Induction coil is used for heating which consumes large amount of power. Heat is derived from peltier module which consumes less power. The cost of heating water with electricity can be quite large. Electricity is not at all an aspect here as heater works on power obtained from PV cells which saves maximum cost. The system is prone to corrosion. Heat exchanger which is Teflon coated is made of stainless steel and is corrosion free. IJOART Table 2: Comparison Between Existing Refrigeration Model And Proposed Model Fig 13 Performance Analyses Between Existing And Thermoelectric Model (Heating Graph) This graph depicts the time taken to heat cabinet from 8°C. This is the deviation observed from domestic refrigeration system and thermoelectric refrigeration system. Thus both Heating & Cooling are achieved using Peltier modules and it is experimentally evaluated. Copyright © 2013 SciResPub. Existing refrigeration model Thermoelectric frigeration model Emits chlouro-fluoro carbon. (CFC’s). It is Friendly. Uses cooling. for It doesn’t require refrigerant Life span with mean time between failures is 87,600 working hours. Long life with mean time between failures is 200,000 hours. Moving parts such us compressors, condensers are present. No moving parts. refrigerant very re- Eco- IJOART International Journal of Advancements in Research & Technology, Volume 2, Issue 6, June-2013 ISSN 2278-7763 10 TOTAL COST Sno Components name Quantity Cost 1 Peltier module (tec112703ht) 3 Rs.2102 ($12.90/pcs ) 2 Solar Panel(12v,5w) 1 Rs.500 ($1.8/watt ) 3 PCB 1 Rs.1075 4 Battery (12v,7.2Ah) 2 Rs.1600 (2x800) 5 Relay (ULN2003) 6 DC fan +fin 7 Relay board 8 LCD 9 PIC 16F877A 10 driver 1 3 1 Rs.20 Rs.375 (3x125) Rs.500 116 ed. The physical dimensions and specifications of the Peltier module are presented. It is observed that the life span of thermo electric heater cum refrigeration system is more than twice the life span of existing conventional refrigeration or heater system. The principle of solar panel along with its specifications and dimensions are displayed. As the future relies heavily on Non conventional energy resources, the Solar powered thermoelectric heater cum refrigeration system will definitely be a large aspect in terms of energy saving capacity and the fact that the system is eco-friendly. The important aspect to be noted is that it is an one time investment and is maintenance free. 12 REFERENCES [1]Taylor, R.A.; Solbrekken, G.L. "Comprehensive system-level optimization of thermoelectric devices for electronic cooling applications", Components and Packaging Technologies, IEEE Transactions on, On page(s): 23 - 31 Volume: 31, Issue: 1, March 2008. [2]Fukutani, K.; Shakouri, Ali "Design of Bulk Thermoelectric Modules for Integrated Circuit Thermal Management", Components and Packaging Technologies, IEEE Transactions on, On page(s): 750 - 757 Volume: 29, Issue: 4, Dec. 2006 IJOART 1 Rs.150 1 Rs.130 Transformer (235V to 12V) 1 Rs.200 11 Temperature (LM35DZ) 1 Rs.32 12 Aluminium cabinet 1 Rs.425 sensor Total cost Rs.7109 11 FUTURE SCOPE To build a real time model replacing both air conditioner and room heater in one system, i.e Thermo Electric Hot And Cold Room Conditioner. 12 CONCLUSION This paper has evaluated the working of Peltier module for producing effective heating and cooling placed inside an aluminium cabinet. By using a temperature sensor inside the cabinet surface, we get the corresponding temperature values for each instant which are displayed in an LCD (Liquid crystal display). The graph between temperature produced inside the cabinet against corresponding time interval are also presented and results are in line with the predictions. The advantages of the thermoelectric heater cum refrigeration on comparison with the existing heater and refrigeration system are elaboratCopyright © 2013 SciResPub. [3]Campbell, L.A.; Wagner, R.; Simons, R.E. "Analysis and characterization of thermoelectric module and heat exchanger performance in a hybrid system cooling application", Semiconductor Thermal Measurement and Management Symposium (SEMI-THERM), 2011 27th Annual IEEE, On page(s): 48 – 53 [4]Solbrekken, G.L.; Yazawa, K.; Bar-Cohen, A. "Heat driven cooling of portable electronics using thermoelectric technology", Advanced Packaging, IEEE Transactions on, On page(s): 429 - 437 Volume: 31, Issue: 2, May 2008 [5]Sharp, Jeff; Bierschenk, Jim; Lyon, H.B. "Overview of SolidState Thermoelectric Refrigerators and Possible Applications to On-Chip Thermal Management", Proceedings of the IEEE, On page(s): 1602 - 1612 Volume: 94, Issue: 8, Aug. 2006 [6]Alley, Randy G. ; Soto, Marco A. ; Kwark, Leon ; Crocco, Paul ; Koester David; “Modeling and Validation of On-Die Cooling of Dual-Core CPU using Embedded Thermoelectric Devices” Semiconductor Thermal Measurement and Management Symposium, 2008. Semi-Therm 2008. Twenty-fourth Annual IEEE Digital Object Identifier: 10.1109/STHERM.2008.4509370 Publication Year: 2008 , Page(s): 77 - 82 [7]Snyder, G. Jeffrey ; Soto, Marco A. ; Alley, Randy G. ; Conner, “ Hot spot cooling using embedded thermoelectric coolers” Bob Semiconductor Thermal Measurement and Management Symposium, 2006 IEEE Twenty-Second Annual IEEE Digital Object Identifier: 10.1109/STHERM.2006.1625219 Publication Year: 2006 , Page(s): 135 – 143 [8]Koester; david ; Venkatasubramanian, Rama ; Conner, Bob ; IJOART International Journal of Advancements in Research & Technology, Volume 2, Issue 6, June-2013 ISSN 2278-7763 Snyder, G. Jeffrey “Embedded thermoelectric coolers for semiconductor hot spot cooling”Thermal and Thermomechanical Phenomena in Electronics Systems, 2006. ITHERM '06. The Tenth Intersociety Conference on Digital Object Identifier: 10.1109/ITHERM.2006.1645384 Publication Year: 2006 , Page(s): 491 – 496 [9]Simons, Robert E. Int. Bus. Machines, Poughkeepsie, NY, USA Chu, Richard C. Semiconductor Therma Embedded thermoelectric coolers for semiconductor hot spot cooling l Measurement and Management Symposium, 2000. Sixteenth Annual IEEE Page(s): 1 - 9 Meeting Date : 21 Mar 2000-23 Mar 2000 Conference Location : San Jose, CA Print ISBN: 07803-5916-X INSPEC Accession Number: 6635951 Digital Object Identifier : 10.1109/STHERM.2000.837055 [10]STEVENS, JAMES W. HEAT TRANSFER AND THERMOELECTRIC FOR A GROUND-SOURCE THERMO DEPT. OF MECH. ENG., MISSISSIPPI STATE UNIV., MS, USA PAGE(S): 68 – 71 PRODUCT TYPE: CONFERENCE PUBLICATIONS MEETING DATE : 29 AUG 1999-02 SEP 1999 ISSN : 1094-2734 PRINT ISBN: 0-7803-5451-6 INSPEC ACCESSION NUMBER: 6644458 DIGITAL OBJECT IDENTIFIER: 10.1109/ICT.1999.843336 DESIGN CONSIDERATIONS GENERATOR 117 Raam Kumar.PH is currently pursuing his B.E (Department of Electrical and Electronics Engineering) in RMK Engineering College, Anna University, Chennai. He is receiving central sector merit scholarship from ministry of Human Resources(HR) GOVERNMENT OF INDIA. His area of interest is Applied thermal Engineering, Transmission & Distribution. Currently he is a member in Institute of Electrical and Electronics Engineers Sai Prasad.S is currently pursuing his B.E (Department of Electrical and Electronics Engineering) in RMK Engineering College, Anna University, Chennai. His area of interest is Applied thermal Engineering, Special Electric Machines. Currently he is a member in Institute of Electrical and Electronics Engineers. IJOART Surith Nivas. M is currently pursuing his B.E (Department of Electrical and Electronics Engineering) in RMK Engineering College, Anna University, Chennai. He has received BEST STUDENT AMBASSADOR AWARD at Waves’12 conducted by COLLEGE OF ENGINEERING, GUINDY, Chennai. His area of interest is Applied thermal Engineering, microprocessor. Currently he is a member in Institute of Electrical and Electronics Engineers. Vishnu Vardhan. D is currently pursuing his B.E (Department of Electrical and Electronics Engineering) in RMK Engineering College, Anna University, Chennai.He is receiving Prime Minister Merit scholarship for Ex servicemen wards, provided by Central Government of India. His area of interests includes Wind Energy forecasting and analysis, Renewable Energy, Applied thermal Engineering, Special Electric Machines. Currently he is a member in Institute of Electrical and Electronics Engineers. Copyright © 2013 SciResPub. Ramya.K is an assistant professor in Electrical and Electronics Engineering department, RMK Engineering College, Kavaraipettai, India. She obtained her M.E. in Power electronics and drives from Jerusalem college of engineering ,Chennai, India. She has published 6 Technical papers in National and International conferences proceedings. She has 0.75 years of teaching experience. She has received AWARD from the governor of TamilNadu, HIS EXCELLENCY THIRU.SURJIT SINGH BARNALA for her UG Project in the year 2010 through AIMO. She also received swamykannu best project award for her PG project in the year 2012. She topped Anna University Rank 1 in her PG. Her research interest includes areas of resonant converters, induction motor drives and renewable sources. Ms K. Ramya is a member of Institute of Electrical and Electronics Engineers. IJOART