081008_miyauchi_poster

advertisement

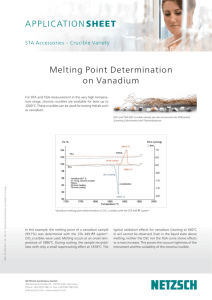

高純度金属バナジウムの新製造法の開発 Development of New Production Process of High Purity Vanadium Metal 1Department Akihiko Resources and production Confirmed reserve Vanadium? ⅢB ⅣB ⅤB ⅥB ⅦB ⅧB ⅠA ⅡA ⅢA ⅣA ⅤA ⅥA ⅦA Hydrogen H 2 Lithium 3 Li Sodium 11 Beryllium Be 4 K 20 Rb 38 Sr Caesium 13 Scandium Titanium Ca 21 Sc Rubidium Strontium Barium Yttrium 39 Y Lutetium Cs 56 Ba 71 Lu Francium 87 22 Vanadium Chromium Manganese Ti 23 Zirconium 40 24 103 Lr 104 Iron Cobalt Nickel Copper B Zr Zinc Tantalum Hf 73 Ta Tungsten 74 C 6 7 Silicon Al 14 N Oxygen Si P 15 O 8 Phosphorus Gallium Germanium Arsenic Silver Cadmium Nb 42 Mo 43 Tc 44 Ru 45 Rh 46 Pd 47 Ag 48 Cd 41 Nitrogen Sulfur 16 S Selenium Fluorine 9 F Neon 10 Chlorine 17 W Rhenium 75 Osmium Iridium Re 76 Os 77 Ir Platinum 78 Gold Pt 79 Mercury Indium 49 In Tin 50 Thallium Au 80 Hg 81 Tl Antimony Sn 51 Sb 52 Te Lead 82 Tellurium Bismuth Pb 83 Bi Polonium Cl 18 Bromine 84 I Ne Ar 36 Kr 106 107 54 Astatine > 105 105 ~ 104 104 ~ 103 103 ~ 102 102 ~ 101 108 (Fe-V-Al (l)) U.S.A 12.4 % Element 20.1 % 15.2 % V metal Amount of production Price (103 ton / year) ($ ・ kg-1) Element V Fe Al Cu Ni Zn ・ Average abundance of vanadium in the earth’s crust; 120ppm. (cf. Common (or base) metals such as Ni: 84ppm, Cu: 60ppm, Zn: 70ppm, Pb: 14ppm). Experimental 58 1,100,000 29,000 15,000 1,600 11,000 Others 1.1 % Catalyst 12.9 % Binder It is important to develop a new production process of pure vanadium metal and vanadium alloy. Total Steel 3 6.42×10 t 86.0% (pure V) Preform reduction process (PRP) Mixing / casting Feed preform Tcal. = 873 K → 1173 K tcal. = 2 hr Calcination Ca -15 V -25 1173 K Leaching and rinsing Liquid Solid Waste solution Vacuum drying V metal powder 900 1000 m.p.(V2O5) 963 K Standard Gibbs energy of formation, DG゚f / kJ mol-1 Reduced preform 1100 Temperature, T / K 1273 K 1200 Casting 1300 Reaction temperature 0 1173 K -200 1273 K Stainless steel reaction vessel -400 Feed preform (V2O5, Flux) -600 CaO Appearance JCPDS # 77-2010 Ca2V2O7 JCPDS # 72-2312 MgO JCPDS # 77-2364 Mg2V2O7 JCPDS # 70-1163 Stainless steel holder 70 Reductant (Ca, Mg) calcination. The obtained feed preform has a mechanical -1200 Ti sponge getter strength at elevated temperature and suitable for handling during processing. 1100 1000 Temperature, T / K 900 1200 1300 Current status Weight change of the samples Table Ex. # X-ray fluorescence spectrometry Experimental condition and mass of samples after each step. Reductant Flux Table Mass of preform, Mass of reductant, Mass of sample Mass of sample Mass of sample wpre / g wR / g after calcination, after reduction, after leaching, V2O5 + 3CaO Ca w1 / g w2 / g w3 / g V2O5 + 3MgO Mg Analytical results of vanadium powder obtained by PRP. Composition of sample (mass%) Ex. # Reductant Fe Cr 3.976 3.474 3.642 1.805 ex.1 Ca CaO 79.0 20.4 - 0.1 0.4 ex.2 Ca MgO 4.226 4.906 3.670 3.955 0.981 ex.2 Ca MgO 85.4 13.0 - 0.3 0.5 ex.3 Mg CaO 4.478 2.573 3.604 4.435 1.071 ex.3 Mg CaO 86.0 2.4 10.6 0.2 0.5 ex.4 Mg MgO 4.158 3.345 3.937 5.086 0.729 ex.4 Mg MgO 99.7 - 0.2 0.01 0.03 ex.1 Flux : CaO, Reductant : Ca ex.4 Flux : MgO, Reductant : Mg (1) After calcination (1) After calcination Intensity, I (a.u.) CaV2O4 V CaO MgO Ca2V2O7 Mg2V2O7 (2) After reduction (2) After reduction 40 60 Angle, 2θ (degree) 80 ・Temperature :1273 K, Time : 6 hr ・When using Mg vapor as a reductant, pure vanadium metal was obtained. The purity of the obtained vanadium powder was 99.7 mass%. ・When using Ca vapor as a reductant, Ca2V2O7 in thepreform was reduced to CaV2O4 after reduction. At this stage, vanadium metal was not obtained. The feasibility of the preform reduction process (PRP), based on the thermal reduction of V2O5, was demonstrated. ・ Complex oxide containing V2O5 was synthesized by the calcination process in order to increase the mechanical strength of feed preform. ・ Vanadium powder with 99.7 mass% purity was obtained by magnesiothermic reduction of feed preform. Future work ・ Investigation of residual oxygen concentration, and evaluation of total vanadium yield. ・ Development of production process of Ti-V alloys. (3) After leaching (3) After leaching 20 by XRF ; value excludes carbon and gaseous elements. Condition for reduction ・ Calcined sample maintained its shape form. → This can be used as a feed preform for reduction experiment. Mg 4.537 The calcination temperature was raised from 873 K synthesized after calcination. Ca CaO Condition for calcination ・ Complex oxides (Ca2V2O7 or Mg2V2O7) was V Ca Angle, 2θ (degree) to 1173 K during 2 hr of calcination period. Flux ex.1 80 synthesize complex oxides (CaxVyOz, MgxVyOz) during -1000 X-ray diffraction pattern 60 The melting point of vanadium pentoxide (V2O5) is low (963 K), and it is difficult to fabricate mechanically strong solid preform. Reduction has to be carried out at temperature higher than 1173 K to maintain enough vapor pressure of Ca or Mg. CaO or MgO was added to feed preform in order to -800 aDetermined 50 PRP is simple and low-cost process for high purity products. Problem TIG welding Reduction process X-ray diffraction pattern 40 Reduction by reductant vapor Stainless steel cover -1400 800 Calcination process 30 Forming Ellingham diagram of oxides Results 20 Preform Ti -20 Features ◎ Suitable for uniform reduction ◎ Flexible scalability ○ Possible to control the morphology of the powder by varying the flux content in the preform ○ Possible to prevent the contamination from the reaction container and to control the purity ○ Amount of waste solution is minimized. ○ Molten salt as a flux can be reduced in comparison with the other direct reduction process. × Difficult to produce reductant and to control its vapor Fe Sintered preform Reduction MxOy+ Flux + Binder -10 -30 800 Tred. = 1273 K tred. = 6 hr V2O5 + 5 R → 2 V + 5 ROx Mg -5 Development of simple and low-cost process for high purity vanadium metal or alloys (Ref. Matsushita Electric Industrial Co., Ltd) -4 Vapor pressure log p° (atm) V2O5 Aim of this study Vapor pressure of metals 0 ◎ Simple and economic process ○ First batch type process with rich scalability × Difficult to control the purity × Repeated removal of Al by the electron beam melting for some applications Vanadium has high hydrogen storage ability. Ti-V alloy draws attention as a negative electrode material of nickel hydride battery, and has a potential to be used for lower-cost and higher-capacity battery. Thermodynamic analysis Flowchart of our process Electron beam melting Features Ti-V hydrogen storing alloy Vanadium production in Japan 39 0.06 3 7 40 3 (Fe-V-Al (l)) Fe-V alloy 15 ~ 25 mass% Al (Ref. Iron and Steel Institute of Japan) Total 3 South 40.1 % 36.6×10 t (pure V) Africa 30.5 % Australia 14.2 % Table Amount of production and price of some metal elements in 2007. V-Al (l) Alloying process V metal Other 43.9 % elements . Reductant (Ca, Mg) China Total 46.0×103 t Russia (pure V) 14.9 % South Africa ・ The 20th largest crustal abundances among the all Flux China Slag V2O5 (s) + Al (s) ( + Fe (s)) Fe-V production Other 6.7 % Japan 2.0 % ・ Low density(6.11 g/cm3) and high melting point (2188 K). Intensity, I (a.u.) 39.1 % V2O5 production 109 Feature of vanadium 20 % HCl aq., Distilled water, Isopropanol, Acetone 23.0 % → 6 V (in Al (l)) + 5 Al2O3 (s) High thermal stability and tensile strength Po 85 At 86 Rn Hg, Ag, Pd, Se Pt, Au, Rh,・・・ 50 % CH3COOH aq., South Africa 3 V2O5 (s) + 10 Al (s) (+ Fe (s)) Hassium Meitnerium ・ ・ ・ 10-1 ~ 10-2 10-2 ~ 10-3 Total 31.1 % 56.3×103 t (pure V) South Africa Xe O, Si Al, Fe, Ca, Na, K, Mg Ti, H, P V, Mn, S, C, Cl,・・・ Cu, Ni, Zn, Nb, Co, Pb,・・・ ・ ・ ・ 26.8 % Radon Table Abundance of elements in the earth’s crust. Crustal abundance (ppm) Total 38.3 % 6 13.0×10 t (pure V) Aluminothermic process In the primary use, vanadium is consumed as an alloy element of steel. China Russia Xenon Rf Db Sg Bh Hs Mt 105 China Krypton Iodine 53 38.3 % Argon Cr 25 Mn 26 Fe 27 Co 28 Ni 29 Cu 30 Zn 31 Ga 32 Ge 33 As 34 Se 35 Br Niobium MolybdnumTechnetium Ruthenium Rhodium Palladium Hafnium 72 V Radium Lawrencium RutherfordiumDubnium Seaborgium Bohrium Fr 88 Ra Carbon Aluminium Na 12Mg 19 55 5 Magnesium Potassium Calcium 37 Boron Russia He Intensity, I (a.u.) 1 Helium Special steel Other 3.0 % ⅧA Commercial production process Application Ores production Other 0.4 % The periodic table of the elements ⅡA Toru H. 2 Okabe of Materials Engineering, Graduate School of Engineering, The University of Tokyo; 2Institute of Industrial Science, The University of Tokyo. Introduction ⅠA 1 Miyauchi , 20 40 60 Angle, 2θ (degree) 80 The reason for incomplete reduction when using ・ Analysis of reduction mechanism by utilizing Ca vapor is not well understood. The difference of the results between Mg and Ca reductant is partially the chemical potential diagram for the system due to the difference of their vapor pressure. The involving oxygen, calcium, magnesium, and vapor pressure of Mg (0.458 atm) is 26 times larger vanadium. than Ca (0.018 atm) at 1273 K.