HAND TOOLS AND BENCH WORK

advertisement

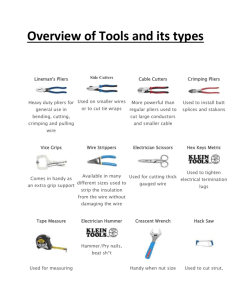

PowerPoint to accompany Technology of Machine Tools 6th Edition Krar • Gill • Smid Hand Tools And Bench Work Section 7 Copyright © The McGraw-Hill Companies, Inc. Permission required for reproduction or display. 22-2 Machine Tool Trade • Two categories – Hand tool – Machine tool operations • Importance of hand tools should not be overlooked • Bench work includes operations of laying out, fitting, and assembling PowerPoint to accompany Technology of Machine Tools 6th Edition Krar • Gill • Smid Holding, Striking, and Assembling Tools Unit 22 Copyright © The McGraw-Hill Companies, Inc. Permission required for reproduction or display. 22-4 Objectives • Select various tools used for holding, assembling, or dismantling workpieces • Properly use these tools for holding, assembling, and dismantling workpieces 22-5 Two Classes of Hand Tools • Noncutting – Include vises, hammers, screwdrivers, wrenches and pliers – Used basically for holding, assembling or dismantling parts • Cutting 22-6 Bench Vise • Jaw Usedcaps to hold madesmall of brass, work securely for to aluminum, or copper protect work surface sawing,the chipping, from marred or filing,being polishing, damaged drilling, reaming, and tapping • Size determined by width of jaws Copyright © The McGraw-Hill Companies, Inc. Permission required for reproduction or display. Solid or swivel base 22-7 Ball-Peen Hammer • Most common • Face: larger striking surface • Peen: smaller, rounded end – Used in riveting or peening operations • Variety of sizes: head mass range 2 oz to 3 lb – Smaller sizes used for layout work – Larger sizes used for general work 22-8 Soft-Faced Hammers • Heads made of plastic, rawhide, copper or lead – Fastened to steel body and replaced when worn – Used in assembling or dismantling parts so finished surface of work not marred • Lead hammers – Used to seat workpiece properly on parallels • Plastic hammer heads – Filled with lead or steel shot – Do not lose shape and last longer than lead hammers • Grasp end of handle for better balance and greater striking force 22-9 Safety Precautions When Using a Hammer 1. Be sure handle is solid and not cracked 2. See head is tight on handle and secured with proper wedge to keep handle expanded in head 3. Never use with greasy handle or when your hands are greasy 4. Never strike two hammer faces together 22-10 Screwdrivers • Two most common types – Standard or flat blade • Blades for smaller make of round stock • Blades for larger often square for leverage – Phillips • Different sizes and styles – Standard shank – Stubby shank – Offset 22-11 Phillips Screwdrivers • + shaped tip for use with Phillips-type recessed screw heads • Manufactured in four sizes: #1, #2, #3, #4 – To suit various-sized recesses in heads of fasteners • Use proper size screwdriver • Hold firmly in recess and square with screw 22-12 Care of a Screwdriver 1. Choose correct size of screwdriver for job • Too small, both screw slot and tip of screwdriver may become damaged 2. Do not use screwdriver as pry, chisel, or wedge 3. When tip of standard screwdriver becomes worn or broken, redress to shape 22-13 Regrinding a Standard Screwdriver Blade • Make sides of blade slightly concave by holding side of blade tangential to periphery of grinding wheel • Grind equal amount off each side of blade • Shape will enable blade to maintain better grip in slot • Retain original taper, width, and thickness of tip and grind end square with centerline • Remove minimum amount of metal • Quench tip frequently in cold water 22-14 Wrenches • Many types used in machine shop work – Each suited for specific purpose • • Name derived from use, shape, or construction Most available in both inch and metric measuring systems 22-15 Open-End Wrenches 1. Single-ended or double-ended • Openings usually offset at 15º angle – – Permits turning nut or bolt head in limited spaces by "flopping" wrench Double-ended have different-size opening at each end 22-16 Box-End 12-Point Wrenches • Completely surround nut and useful in close quarters where only small rotation of nut can be obtained at one time • Box end has 12 precisely cut notches around inside face – Notches fit closely over points on outside of nut – Cannot slip when proper size used • Have different size at each end 22-17 Socket Wrenches • Similar to box wrenches – Twelve points and surround nut • Types of drives – Ratchet – Torque-wrench handles • Used when nuts or bolts must be tightened to within certain limits 22-18 Adjustable Wrenches • May be adjusted to within certain range to fit several sizes of nuts or bolt heads • Useful for odd-size nuts or when proper size not available – Can slip when not properly adjusted to flats of nut 22-19 Allen Setscrew Wrenches • Commonly called hex keys • Hexagonal and fit into recesses of socket head setscrews • Made of tool steel • Available in sets to fit wide variety of screw sizes – Indicated size is distance across flats of wrench • ½ outside diameter of Allen setscrew in which used 22-20 Pin Spanner Wrenches • Specialized wrenches supplied by machine tool manufacturer for use on specific machines • Supplied in various sizes • Fixed-face spanners and adjustable-face spanners positioned in two holes on face of special nut or threaded fitting on machine • Hook-pin spanner used on circumference of round nut – Pin of spanner fits into hole in periphery of nut 22-21 Hints on Using Wrenches 1. Always select wrench that fits nut or bolt properly 2. Pull rather than push on wrench 3. Always be sure nut is fully seated in wrench jaw 4. Use wrench in same plane as nut or bolt head 5. When tightening or loosening nut, give it sharp quick jerk (more effective than steady pull) 6. Put drop of oil on threads when assembling a bolt and nut to ensure easier removal later 22-22 Pliers • Useful for gripping and holding small parts for certain machining operations or when assembling parts • Many types and sizes • Names by shape, function or construction 22-23 Types of Pliers • Combination or slip-joint pliers – Adjustable to grip both large and small work • Grip work when small holes must be drilled or for bending or twisting light, thin materials • Side-cutting pliers – Used mainly for cutting, gripping, and bending of small diameter (1/8 in. or less) rods or wires 22-24 Types of Pliers • Needle-nose pliers – Available in both straight- and bent-nose types – Useful for holding very small parts, positioning them in hard-to-get-at places and bending wire • Diagonal cutters – Used solely for cutting wire and small pieces soft metal 22-25 Types of Pliers • Vise-grip pliers – Extremely high gripping power because of adjustable lever action • screw in handle allows adjustment to various sizes – Several different styles: standard jaws, needle jaws and C-clamp jaws 22-26 Hints on Using Pliers 1. Never use plier instead of wrench 2. Never attempt to cut large-diameter or heat-treated material with pliers 3. Always keep pliers clean and lubricated