File - Introduction

advertisement

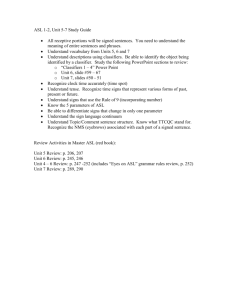

Page 1 Operations Management Applied Research Project 06 November 2013 Applied Research Project The Authorized Stockage List (ASL) Review Board Process Prepared for: Shaun Stewart Southwestern College Wichita, Kansas Prepared by: Jason D. Yearwood Page 2 Operations Management Applied Research Project 06 November 2013 EXECUTIVE SUMMARY INTRODUCTION An Authorized Stockage List (ASL) is maintained by each Support Supply Activity (SSA), the SSA is no more than a warehouse with different classes of supply depending on the unit requirements. Depending on your location and your unit’s Standard Operating Procedures (SOP), the units that own each SSA have to complete an ASL review. The role of the SSA in sustaining readiness is measured in terms of effective customer support by ensuring the proper amount of supplies are on hand, timely customer request and receipt processing, inventory accuracy, and deployment and mobility rates (usacac.army.mil, 2010). This paper will focus on the ASL review process, the phases of the process, who sits on the ASL review board, its importance to troops in a deployed and garrison environment and how technology enhanced the data gathering process. The ASL review is a demand analysis requirement that ensures the right parts for the equipment is stocked, readily available, and replenished to prevent degradation of the missions that could significantly affect the garrison mission and also the security of troops in theatre as well as threaten support to coalition forces. Page 3 Operations Management Applied Research Project 06 November 2013 ANALYSIS The research conducted will discuss the history and phases of an ASL review board, the importance of an ASL review board, who sits on an ASL review board, the effects it has on readiness, and how technology and studies played a great role in enhancing the way data relevant to conducting an ASL review board. CONCLUSION The ASL review board process is a process that is critical to mission success in both a garrison and especially a deployed environment. The ASL review board process not only ensures the right part is readily available, the correct quantity is on hand for the unit’s equipment, timely customer request and receipt processing but it saves the Army money in the long run by eliminating, increasing or decreasing the stockage level of parts that are not utilized by the unit or the demand levels are not up to standard. The review process is similar to the technique of lean warehousing. RECOMMENDATION This ASL review board process is mandated by the Department of the Army at different time intervals depending on the unit’s location, it is a critical tool that is and will be useful as the Army draws down its forces, finds ways to save money, and cut costs. This ASL review board process is a lengthy process, but it ensures that customer requirements are being met by stocking the right parts and it will eventually cut waste and spending by eliminating the wrong parts, adding new parts, or decreasing the numbers for parts that are no longer a priority to the unit and its mission. Units across the Army realize the review process’ importance and recommend that this process continues as long as there is a possibility of waste in the logistics system. Page 4 Operations Management Applied Research Project 06 November 2013 TABLE OF CONTENTS INTRODUCTION ............................................................................................................................. 5 ANALYSIS ....................................................................................................................................... 6 CONCLUSION ................................................................................................................................. 7 RECOMMENDATION ..................................................................................................................... 7 APENDICIES……………………………………………………………………………………….8 WORK CITED…………………………………………………………………………………….10 List of Illustrations Figure 1 Summary of data from analysis for each recommended action…………………………...8 Figure 2 Line by Line recommendation of parts considered.………………………………………9 Page 5 Operations Management Applied Research Project 06 November 2013 INTRODUCTION The Support Supply Activity (SSA) depends on the boards that regularly review the Authorized Stockage List (ASL) to know what repair parts to stock. Anyone that is a customer of the SSA must have knowledge of the review process in order to understand how repair parts are stocked and have a basic understanding of how the right parts affect maintenance operations and readiness. ASL reviews are done at different intervals depending on the unit’s location (Rosa, 2000). In a deployed environment the ASL review is done every four months, in Europe, every six months and in the 50 states, every 12 months, these timelines are subject to change by local policies and command guidance (B. Hornbaker, personal communication, September 22, 2013). The ASL review board is critical in theatre because different types of units occupy the bases and the parts that are routinely stocked in the warehouse for the Infantry battalions and their equipment may not be sufficient for an Engineer battalion and their equipment. The review process is a three phase process; the first process is to gather the data from the software being used by the warehouse to capture demand history analysis, the second phase starts with analyzing the data and coming up with possible additions, deletions, increases or decreases of repair parts. The final phase is where the actual board meets to discuss the recommendations and findings from the analysis of the data. The members of the board include the support operations officer (who chairs the board), the officer in charge of the SSA (warehouse), the maintenance officers for the units supported, and any other individuals with technical expertise with a supply and logistics background (Rosa, 2000). Having the right parts on hand, at the right time is critical to the mission in theatre. Units depend on the SSA to stock the parts that help them continue the fight as far forward as possible and have continuous sustainment operations. Page 6 Operations Management Applied Research Project 06 November 2013 ANALYSIS The historical data is the primary source along with the board participants experience in deciding what parts the SSA is going to stock. Ensuring that all customer requirements are met when it comes to stocking parts in the warehouse is the focus for the month that it takes to complete an ASL review board. The board uses the Standard Army Retail Supply System (SARSS) 2B analysis process. Line by line board members review each item being considered. Board members of the ASL review bring their knowledge of critical repair parts with them as well as, the demand histories of their on hand parts. The SARSS will compute recommended stockage levels for the board to follow unless overriding considerations exist for a specific part. Recommendation for a current part that is stocked is based on the number of demands, quantities and order ship time. The primary consideration for authorizing addition, retention and deletion of parts from the ASL is the demand criteria. Nine demands in a 12-month period authorize the board to add and create a location for that part to be now stocked in the warehouse. Three or more demands authorize the board to retain that part in the warehouse (Rosa, 2000). As the Army transform into a modular force, it cannot afford ineffective warehousing or inventories in a deployed or garrison environment (usacac.army.mil, 2010). Page 7 Operations Management Applied Research Project 06 November 2013 CONCLUSION The results of the ASL review board saves money, reduces repair time for non-mission capable equipment and enhances customer satisfaction by stocking the right part and the right amount of parts to support the mission. The ASL review process tailors the parts listing to specific requirements of the supported units and also maximizes warehouse storage space by deleting non-essential items. Logisticians must understand the ASL review board process enables the warehouse to stock the repair parts that customers need to sustain readiness of unit equipment. Readiness certainly increases by providing customers with requested repair in a timely manner. Army maintenance depends upon availability of repair parts. If a warehouse fails to conduct a review board process, this significantly affects the readiness of the supported units (Rosa, 2000). Keep in mind as the mission requirements change; the warehouse must update their stocked parts list to reflect the new changes in equipment. RECOMMENDATION While the ASL review board is mandated, it was recently recommended that units in a deployed environment conduct the review board every 60 days instead of every 120 days. This recommendation came as a result of the massive draw down in theatre and the lack of assets in the states. The concept behind the change is why stock so many parts in theatre when we are drawing down and there are less equipment and personnel in theatre. As vehicles and equipment are retrograding back to U. S. bases, there is no need to keep warehouses full of parts for vehicles that are in the states. It is recommended that we keep these review boards going and try to reduce the time it takes to conduct all three phases of the ASL review board process. Page 8 Operations Management Applied Research Project 06 November 2013 APPENDICES Figure 1 Summary of data from analysis for each recommended action. Table 3 provides a summary of the recommendations by action. SSA (Warehouse) Action WXE # NIINs Change in Extended Cube Extended Cube Change in RO value Extended # RO Value Demands 15,994 0 0 $0 $0 34,812 361 WXE ADD 78 131 131 $369,005 $369,005 WXE DEC 1,345 -4,274 12,008 $-17,832,560 $47,954,99 10,234 0 WXE DEL 459 -2,878 0 $-3,844,346 $0 WXE INC 126 739 1,701 $1,523,650 $3,883,938 1,234 WXE NOC 4,456 0 19,234 $0 $57,773,49 39,456 5 WXE ROP 90 0 123 $0 $295,071 212 756 The ROP action denotes NIINs for which we are changing the ROP, but not the RO. Typically this occurs if you have an order quantity (OQ = RO –ROP) that is greater than one for expensive NIINs or in which simply adjusting the ROP results in satisfactory performance (determined via simulation against your demand streams) without having to adjust the RO (item should still fit in the same location, potentially reducing workload in the SSA). The line for NOC, which stands for 'no change', indicates the current RO and ROP on the ABF will remain the same (no change recommended). The NIINs with an action of “NOC” in the phase 2 review file exist only if the extended dollar value (the current RO times the unit price) is greater than $500,000 or extended cube (current RO times the cube) is greater than 50 cubic feet. The line with a blank action field reflects NIINs that had activity but demands were insufficient to be recommended for stockage. This illustrates the challenge of achieving high ASL fill rates as there are a large number of NIINs with very low demands. Page 9 Operations Management Applied Research Project 06 November 2013 Figure 2 Line by Line recommendation of parts considered INC ADD ADD ADD INC DEC DEC DEC DEC DEC DEC DEC DEC DEC DEL DEL DEC DEL DEC DEL DEL DEC DEC DEC DEL DEL 9150 8030 8040 8040 8040 8030 8040 4920 8030 8010 6130 8010 9150 8115 9150 7920 5965 4920 4920 4920 4920 6810 5965 8115 4330 1740 002234134 000087198 011074000 008658991 004637042 001806222 001450020 012161940 002512312 005825318 015450375 013316109 001806266 014440212 007822627 002601279 015074318 015562562 014567141 011083484 011399689 008556160 015213223 014440206 015222007 015421099 GL KT KT KT KT BT TU SE TU GL EA PT CN EA QT BX EA EA SE EA SE CN EA EA EA EA ADD-Add part to inventory INC-Increase Stockage level DEC-Decrease Stockage level DEL-Delete part from inventory HYDRAULIC FLUID,PET SEALING COMPOUND ADHESIVE ADHESIVE ADHESIVE SEALING COMPOUND ADHESIVE SET,LEADING EDGE,DR ADHESIVE PRIMER COATING POWER SUPPLY ENAMEL LUBE OIL A&E 8 OZ CN SLEEVE,BOX LUBRICATING OIL,AIR TOWEL,MACHINERY WIP HEADSET,ELECTRICAL COMPOSITE REPAIR SE TEST SET,FUEL VENT SLING,LIFTING,ENGIN RIGGING SET,CONTROL ISOPROPLY ALCOHOL ACS HEADSET-MICROPHONE PALLET BASE,SHIPPIN FILTER UNIT,FLUID,P TRAILER,GROUND HAND Page 10 Operations Management Applied Research Project 06 November 2013 Works Cited Center for Army Lessons Learned [CALL], 2010. Handbook 10-19, Chp. 3., Maintenance and Supply Readiness. Retrieved from http://usacac.army.mil/cac2/call/docs/10-19/ch-3.asp. Rosa, Yesenia. (2000). Authorized Stockage List (ASL) Review Board Process. Retreived from http://www.quartermaster.army.mil/oqmg/professional_bulletin/2000/winter2000/ Authorized_Stockage_List_Review_Board_Process.htm.