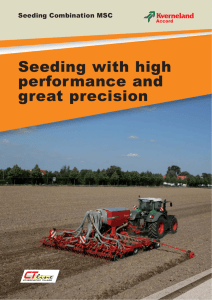

s-drill

advertisement

Kverneland Accord s-drill Product information 2016 Kverneland Accord s-drill Cultivator-mounted seed drill s-drill – Content • Basic information • Transport • Seed hopper • Interfaces / track marker • Fan • Coulter bar • Land wheel • Seed coulter / Following harrow • Electronics • Technical data • Main features s-drill – Basic information • Hopper content: 1.050 litres (no hopper extension) • Filling height: 2.03m (with KvG power harrow ) • Total height: 2.85m (track marker 3m working width) • Length (NG-S, 500mm packer roller, CX-coulter, S-tine following harrow): 3250mm • Working width: 3 / 3.5 / 4m • Transport width: 3 / 3.5 / 4m s-drill – Transport • Fast changing from working to transport position (Track marker, side plate, land wheel…) • Lighting equipment in accordance to current road regulations for safe road transport (option) s-drill – Seed hopper • 1.050 l standard hopper capacity (no extension possible) • Loading step for easy and safe filling • Stable hopper cover made of steel • Easy emptying of the hopper s-drill – Calibration test • Easy calibration test by spindle or electric drive ( ESA) • Calibration kit (bag and scale) available as an option • Easy access to the metering device, adjustment without any tools s-drill – Interfaces • Easy coupling and uncoupling for solo operation of the power harrow • Coupling via Kverneland saddle triangle • Mounted via „UNI“ triangle – seed drill can be mounted on almost all powered or non-powered cultivation implements s-drill – Track marker • Track marker fixed on the coulter bar • Shear-bolt overload protection • Adjustable to central marking for all working widths • Spare screw inside the bracket • Plane disc as standard, notched disc as option • Alternatively the track markers can be mounted directly on the soil prep. implement s-drill – Fan • Fan housing made of antistatic plastic • Belt control available as option • Hydraulic fan drive available as option (38 l / min) • Locking device available for the change of the belt and/or to relieve the tension on the belt during longer nonoperational times (winter) s-drill – Coulter bar • Coulter bar is connected to the basic frame via parallelograms • Mech. coulter bar adjustment as standard • Height adjustment via spindle • Hydr. coulter bar adjustment available as an option • Hydr. coulter bar lifting device available as an option s-drill – Land wheel • Land wheel (Ø = 650 mm) running on cultivated soil (smooth run) • Direct drive of the metering device via telescopic bar (with mechanical drive) • Integrated brake to avoid “overdosing” on head lands s-drill – Seed coulter • 2 rows of Suffolk coulter (3 rows as option) • Worldwide patented CX disc coulter with flexible plastic disc and convex steel disc with self-cleaning effect • Max. 25 kg coulter pressure • Depth adjustment via coulter pressure • Small / large press wheels as option CX-II coulter • Big dimensioned casted iron coulter arm with high professional bearings approved by our big sized seeder • Maintenance free no greasing points due to long life bearing protection • • • • • • • coulter pressure: up to 35 kg disc cutting angle: 5,4 ° steel disc: Ø 325 mm x 3mm flex disc: Ø 250 mm Series press wheel: Ø 250 mm x 42 mm row staggering: 445 mm depth adjustment: by bolt CX-II coulter Performance- keeping the seeding depth CX-II disc with flexible press wheel setting Seeding depth okay seeding depth okay seeding depth too deep seeding depth okay Flexible press wheel: Loosing only one time the requested seeding depth when facing obstacles in the field. Parallelogramm linked disc coulter with rigid press wheel Seeding depth okay okay seeding depth too high seeding depth too deep seeding depth Rigid press wheel: Loosing two times the requested seeding depth when facing obstacles in the field due to rigid connection between disc and press wheel CX-II coulter press wheel adjustments • • • • • Press wheel in fixed position Smooth conditions Plain and even seed bed No stones Not many residues • • • • • Press wheel in flexible position Rough conditions Rough seed bed Stones on the field Many residues • Press wheel in lifted position • Extreme wet conditions • e.g. in late autumn after sugar beet harvest s-drill – Following harrow • S-tine following harrow 8 or 10mm • Double row precision following harrow s-drill – Following harrow • Setting angle and pressure adjustable (complete lifting possible) • Adjustable to all soil conditions s-drill – Electronics FGS • Simple tramlining system • LED displays tramline status • Manual switch for individual adaptation • Hopper low level sensor • Voltage control SIGNUS • Advanced tramlining system; including special rhythms • Display of working speed, fan revolution and active tramlining • Metering device control, electric seed rate adjustment • Hopper low level sensor • Hectare counter (3 different types) s-drill – Electronics IsoMatch Tellus Go • One display for electric machine control ESA • Display of working speed, fan revolution and active tramlining • Metering device control, electric seed rate adjustment IsoMatch Tellus The next generation universal ISOBUS Terminal – IsoMatch Tellus • Two ISOBUS interfaces in one terminal • Display of working speed, fan revolution and active tramlining • Metering device control, electric seed rate adjustment • Hopper low level sensor • Hopper low level sensor • Hectare counter (3 different types) • Hectare counter (3 different types) • Diagnostic and storage system • Diagnostic and storage system • Useable also for different KvG implements • GPS compatible s-drill PRO – Electronics – IsoMatch Tellus The next generation universal ISOBUS Terminal – IsoMatch Tellus • Two ISOBUS interfaces in one terminal • Multifunctional ergonomic design • ISOBUS Stop Button The IsoMatch Tellus is the first ISOBUS terminal in the world to show two different machines in just one display without the need to constantly switch between the displays of the two machines s-drill – Technical data Model s-drill Hopper capacity (litre) 1.050 Hopper cover (Steel, foldable, sealed) Standard Mech. fan drive 1000 U / min Standard Hydr. fan drive Option Hydr. folding track marker Option Micro metering Standard Seed rate 2-380kg/ha Standard Mech. hectaremeter Option Mech. Half-width shut off Option Tramlining system FGS Option Tramlining system Signus Option Elektronic control ISOBUS 11783 Option Standard tramline shut-off valve / Combi valve Option Pre-emergence marker Option Working- and transport width (m) 3.0 / 3.50 / 4.0 Lighting (road light / working light) Option Weight (3m; 24CX coulter, 8mm following harrow) 685 kg s-drill – Main features • 1050 l hopper capacity for reduced set-up times and large performance • Overload protected track marker arms • Integrated brake of the land wheel to avoid “overdosing” on head lands • Adjustment of the metering device for all sorts of seeds without any tools • Seed emptying chute for easy removal of remaining seeds and cleaning • Optional electronic machine control according to DIN ISO 11783 (ISOBUS) • Easy adjustment to any cultivation implements available • Easy uncoupling of the seed drill for solo operation due to linkage via saddle triangle Kverneland Accord s-drill : More than just a drill