ppt - SLAC

advertisement

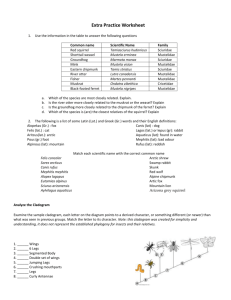

GLAST LAT Project May 25, 2006: Pre-Environmental Test Review GLAST Large Area Telescope: Gamma-ray Large Area Space Telescope Pre-Environmental Test Review Integration and Test Ken Fouts SLAC Integration and Test Presentation 8 of 12 1 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Overview • Review Current Status – LAT Instrument Configuration – Procedure Status • Review Plan for Environmental Test – Organization – Pathfinding Summary – LAT I&T Operations at NRL – EGSE/MGSE Readiness – Test Configurations and flow • Schedule Review Integration and Test Presentation 8 of 12 2 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Current Configuration • As built configuration – LAT-DS-1624 LAT Top Assembly – Radiators – ACD, Radiator & LAT MLI Integration and Test Presentation 8 of 12 3 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review I&T Process Procedures Document Title Status LAT-PS-03263-01 Fastener Installation and Torqueing Procedure Released LAT-PS-04727-01 Connector Mate and Demate Released LAT-MD-04601-01 LAT I&T eLog Book Implementation Plan Released LAT-PS-03291-01 Flight Hardware Bag and Purge Procedure Released LAT-PS-04436-01 AeroGo Bearing Reference Guide Released LAT-PS-04511-04 LAT Data Collection Procedure Released LAT-MD-01533-01 LAT EGSE Plan Released I&T Standard Processes will continue to be used at NRL Integration and Test Presentation 8 of 12 4 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Key Documents for Environmental Test Document Title Status LAT-PS-6898 LAT Environmental Test Implementation Plan In Signoff LAT-PS-07929-01 LAT Shipping Container Procedure Released LAT-PS-07728 LAT Environmental Test Handling Procedure In Signoff LAT-MD-02717-01 LAT Environmental Test Sequence Released LAT-MD-01196-03 LAT Dynamics Test Plan Released LAT-MD-01600-03 LAT Thermal Vacuum Test Plan Released LAT-MD-02726-01 LAT EMI/EMC Test Plan Released LAT-DS-7411 LAT Environmental Test Wiring Diagram Released Key Environmental Test Planning has been completed Integration and Test Presentation 8 of 12 5 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Environmental Test Configuration Drawings Drawing Title Status LAT-DS-06188 Acoustic Test Configuration Assembly Released LAT-DS-06185 Thermal-Vacuum Test Configuration Assembly Draft LAT-DS-06187 Horizontal Vibration Test Configuration Assembly Released LAT-DS-06190 Vertical Vibration Test Configuration Assembly Released LAT-DS-06186 Handling Configuration Assembly Released LAT-DS-06184 Transport Configuration Assembly Released LAT-DS-06189 EMI/EMC Test Configuration Assembly Released LAT-DS-06191 Mass Properties Configuration Assembly Draft LAT Instrument Configuration for Environmental Tests is documented Integration and Test Presentation 8 of 12 6 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review I&T Documentation Test Performance and Operation Plan LAT-MD-02730 Drawings Test Sequence LAT-MD-00676 (Mechanical Assembly, Cabling, EGSE/MGSE interface, etc.) LAT Environmental Test Plans I&T Operating Processes and Procedures Assembly Instruction Data Sheet (AIDS) Electronic Logbooks (Component installation, Mate/Demate, Etc.) QA and Archive Non-Conformance Report (NCR) CM processes for document control, release and completion will be maintained. Integration and Test Presentation 8 of 12 7 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review LAT Environmental Test Organization Ken Fouts I&T Manager E. Grove, Deputy B. Raynor NRL Resource Manager Dynamics Test J. Ku EMI/EMC M. Lovellette Rqmts & Planning K. Fouts N. Johnson TVAC J. Armiger NRL Operations P. Dizon Environmental Test Management Team is in place work planning and scheduling Integration and Test Presentation 8 of 12 8 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review LAT I&T Team Subsystem I&T Support ACD – Martin Kocian/Dave Thompson CAL - Eric Grove DAQ – Gregg Thayer Elec - Dave Nelson FSW - Mike DeKlotz SAS - Richard Dubois TKR -Hiro Tajima Controls - Shannon Leone QA - Doug Bartholomew LAT Integration and Test Ken Fouts, Manager (SU-SLAC) Eric Grove, Deputy Manager (NRL) Larry Wai LAT I&T Data Manager WBS 4.1.9, 4.1.9.1 Brian Grist Eliazar Ortiz Jeff Tice Electrical Lead Engineer Mechanical Lead Engineer Material Logistics Lead John Canfield, S&E Associate - Electrical Phuc Hoang, S&E Technician - Electrical Albert Nguyen, Electrical Engineer Roger Williams, S&E Associate - Electrical Drew Roberts, Electrical Engineering Contractor Patrick Young, Electrical Engineer Mechanical Design Support Marc Campell, Manager (SU-SLAC) WBS 4.1.9.4 Leo Manger, S&E Associate - Mechanical Dave Kiehl, S&E Technician - Mechanical Tom Neiland, S&E Technician - Mechanical Mark Molini, S&E Associate - Mechanical Online Software Particle Test Ric Claus, Manager (SU-SLAC) WBS 4.1.9.5 Manager (SU-SLAC) WBS 4.1.9.7 Gary Godfrey, Domi Celestino, Inventory Clerk Science Verification, Analysis, and Calibration Anders Borgland, Manager (SU-SLAC) WBS 4.1.9.9 Bill Olson Jim Panetta Mechanical Engineer Engineering Physicist Arthur Scholz Mechanical Engineer Selim Tuvi Eric Charles Software Developer Software Developer Lester Miller Warren Focke Engineering Physicist Engineering Physicist LAT Collaboration I&T Coordination Eduardo do couto e silva (SU-SLAC) LAT I&T Team has a proven track record for safe program execution Integration and Test Presentation 8 of 12 9 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Pathfinding Summary (1 of 2) LAT Pathfinding Activity Documented in LAT-MD-07727 Objective: Identify and mitigate mechanical operations/handling risk. • Pathfinder Lifting Operations – Installation into and Removal from Shipping Container with the GPR. – Installation into and removal from the Test Stand with GPR – Onto and off of the Vibe Table with the GPR – Test Stand Turnover with Complete Mass Simulator and SLAC lift slings – Installation of the rotated test stand and LAT onto the TVAC table/Trolley • Pathfinder Move Operations – Transport weighted shipping container – Move LAT in the test stand from clean tent to Sine Vibe. – Move LAT and test stand from clean tent to EMI test chamber. – Move LAT and test into Acoustic test chamber. – Move LAT and test stand TVAC staging area and into chamber. LAT-PS-07728 LAT Handling Procedure was developed during Pathfinding Integration and Test Presentation 8 of 12 10 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Pathfinding Summary (2 of 2) • Pathfinding Miscellaneous Operations/Installations – Radiator installation/removal procedures including timed trial runs (adhesive pot life) – TVAC prep work – mount S/C simulator sink plate – TVAC configure – another rotation and install on Table/Cart • Improved handling procedures for installation and use of test stand extensions – Installation of TVAC STE – heater cages, ACD sink plates – Transport into TVAC chamber and working around LAT and STE inside chamber. – TVAC cable installation and routing Pathfinding activity mitigated potential risk for critical handling operations Integration and Test Presentation 8 of 12 11 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review I&T Operating Plan • The detailed LAT I&T schedule is maintained in MS Project by the I&T Scheduler. – Schedules will be updated daily via the afternoon meeting with progress from that day. • NRL Operations – Normal work time will be 7:00am-8:00pm. “Shifts” will run nominally 7:00am-4:00pm and 12:00am-8:00pm. Shifts will be adjusted to go around the clock as the need arises. – Daily morning meeting at 7:00am and afternoon meeting at 3:00pm. – Daily phone tag-up to SLAC at 4:00pm. – Minimum staff when the instrument is under test is 2 LAT Electrical Test staff members. – TVAC will be staffed 24/7 – Extended shifts and/or Saturdays will be used to maintain schedule as required. • LAT Instrument Handling – LAT will be configured in the portable clean tent whenever possible. – The LAT will be bagged to maintain cleanliness when outside of the controlled environment. – Cleanroom and ESD protocol will be maintained during all LAT handling operations. NRL Operating plan is similar to SLAC Operations Integration and Test Presentation 8 of 12 12 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Troubleshooting in I&T • No troubleshooting will be done without appropriate disposition on an NCR. • When an anomaly occurs: – The test set-up is frozen – The instrument and test equipment is safed. – The test set-up and instrument configuration is reviewed and documented by the Test Conductor. – Test conductor notifies the TD, Subsystem Engineer and QA. • QA initiates an NCR with information from TC and convenes MRB. – At a minimum, MRB consists of the Test Director, Test Conductor, Subsystem Engineer and QA. • MRB will provide detailed disposition for troubleshooting. • The test procedure will be redlined or a separate procedure will be written (as defined by MRB) to document the troubleshooting activity defined in the disposition. Troubleshooting will be done in accordance with the I&T Implementation Plan Integration and Test Presentation 8 of 12 13 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Problem Resolution in I&T Problem Observed Inspection, Testing, Data Analysis (HW, SW, Data) Issue Closed False Alarm! Corrective Actions Test Conductor Error No Non Conformance Report (NCR) Test Procedure/Set Up Error Flight HW Damaged Test Equipment Problem Categorize by Test Conductor and/or Test Director Yes Possible Flight HW Failure HW MRB Troubleshoot HW Root Cause Identified Corrective Actions Possible Flight SW Failure SW JIRA Troubleshoot SW Root Cause Identified Corrective Actions CCB Action Problem Resolution will continue to use the NCR process Integration and Test Presentation 8 of 12 14 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Network Configuration for LAT Operations at NRL VSC and Power Rack will move with the LAT Instrument Integration and Test Presentation 8 of 12 15 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review LAT I&T CCB Controls Test Configuration • LAT-MD-03492 LAT I&T CM/CCB Procedure establishes the process for configuration control of flight and test software installed on the LAT and EGSE test stations. • LAT I&T CCB is held on an as needed basis and requires the following minimum representation: I&T Manager (CCB Chair) I&T Electrical Test Lead Systems Engineering Online Manager Flight Software Quality Assurance DAQ Electronics Software packages listed below are controlled by CCB in the locations listed LAT I&T CCB has been successful in controlling software installation/changes Integration and Test Presentation 8 of 12 16 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Environmental Test MGSE/STE • Transport Container – Manufacture complete; Analyses complete – Proof test complete – Demo Road Test complete – Available at SLAC • Test Interface Plate – Complete • Test Stand/Spreader Bars – Complete, used in pathfinding • TVAC Sink Plates – ACD & S/C Simulator – Complete, used in pathfinding 2 • TVAC Cal-Rod Cage – Complete, used in pathfinding 2 • Acoustic Simulator – Complete • Mass Properties Plate – Load Cell Interface in manufacture – Complete All MGSE has been used in dry run or pathfinding activity Integration and Test Presentation 8 of 12 17 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review GPR, Lift Fixture Proof Test at SLAC Rotation Stand w/ GPR Proof Test Integration and Test Presentation 8 of 12 Proof Test of the 4x4 Lift Fixture and GPR 18 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Facilities • Thermal Vacuum Test – Cables and Port Plates – complete – Mechanical analyses complete – Trolley (cart) – complete, used in pathfinding – Chamber rails upgrade – complete and proof tested – Pathfinding 2 – complete – Chamber refurb, cleaning and recommissioning - complete – GSE bakeout and STE Validation – ECD: 5/16/06 • Acoustic Test – Ramp manufacture complete • Vibration Test – Expander head load frame procurement - delivered – Load frame manufacture – complete – Installation and proof test - complete • EMI/EMC Test – Ramp manufacture – complete, used in pathfinding NRL Facility has been upgraded to meet LAT Operational Requirements Integration and Test Presentation 8 of 12 19 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Environmental Test Sequence Baseline C F Rev date: 24 April 2006 Ship to NRL S NRL Post-Ship at SLAC Receive, Unpack Sine Vibe C L L Pre Pre-TV C S T-Bal L S T-Cycle L C L L Mount Radiators EMI/EMC T L E L Acoustic L L Post- Axis Final C F S Remove Radiators Weight CG Pack LAT Ship to Spectrum TESTING IN THERMAL VAC CHAMBER Integration and Test Presentation 8 of 12 L Limited Performance Test F LAT Functional and FSW Test C Comprehensive Performance Test T TCS Functional Test S SVAC Test E EMI/EMC Emissions/Susceptibility Test 20 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Sine Vibe Configuration Integration and Test Presentation 8 of 12 21 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Vibration Facility Layou Integration and Test Presentation 8 of 12 22 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Radiator Installation Radiator flange access Radiator installation test Integration and Test Presentation 8 of 12 23 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review EMI/EMC Test Configuration Integration and Test Presentation 8 of 12 24 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review EMI Chamber Layout Integration and Test Presentation 8 of 12 25 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Acoustic Test Configuration Integration and Test Presentation 8 of 12 26 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Acoustic Test Layout Integration and Test Presentation 8 of 12 27 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review TVAC Configuration Integration and Test Presentation 8 of 12 28 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Thermal STE Heater Cage Configuration S/C Sink Plate Configuration Installation of ACD Sink Plate Panels (5) Integration and Test Presentation 8 of 12 29 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review TVAC Layout Integration and Test Presentation 8 of 12 30 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Environmental Test Schedule (1 of 3) Integration and Test Presentation 8 of 12 31 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Environmental Test Schedule (2 of 3) Integration and Test Presentation 8 of 12 32 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Environmental Test Schedule (3 of 3) Integration and Test Presentation 8 of 12 33 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Staffing Plan • Current staffing plan for NRL: – Single long shift 5-6 days per week for Sine Vibe, Acoustic, EMI/EMC tests. – 24/7 staffing for TVAC duration. – SLAC will average 14 people including • I&T Management • I&T Electrical • I&T Mechanical • Mechanical Design • Online • SVAC • QA • DAQ Integration and Test Presentation 8 of 12 34 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Staffing Plan (1 of 2) 5/1/2006 5/29/2006 6/5/2006 6/12/2006 6/19/2006 6/26/2006 Sine Vibe TestInstall Radiators EMI Test Acoustic Test 7/3/2006 7/10/2006 7/17/2006 7/24/2006 7/31/2006 TVAC Prep TVAC Open Door 8/7/2006 8/14/2006 8/21/2006 8/28/2006 TVAC Test Remove Radiators Wt & CG 9/4/2006 Ship I&T Electrical B. Grist J. Canfield D. Roberts P. Hoang P. Young R. Williams A. Nguyen Sub-Total 1 1 1 1 1 5 1 1 1 1 1 5 1 1 1 1 1 1 5 1 1 1 1 5 1 1 1 1 1 1 1 1 1 4 4 1 1 1 1 5 1 1 1 1 1 5 1 1 1 1 1 1 5 1 1 1 1 5 1 1 1 1 1 5 1 1 1 1 1 1 5 1 1 1 1 5 1 1 1 1 1 1 1 1 1 1 5 5 1 1 1 1 4 1 1 1 1 1 5 I&T Mechanical E. Ortiz L. Manger T. Neiland D. Kiehl M. Molini Sub-Total 1 1 1 1 3 1 1 1 4 1 1 1 1 4 1 1 1 1 3 1 1 1 1 1 3 1 4 1 1 1 1 3 1 1 1 4 1 0 0 0 1 1 1 4 1 1 1 1 4 QA J. Cullinan D. Bartholomew YC Liew E. Rodriguez J. Marshall Sub-Total 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 0 0 I&T Online R. Claus J. Panetta S. Tuvi L. Miller Sub-Total 1 1 1 1 1 Integration and Test Presentation 8 of 12 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 35 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Staffing Plan (2 of 2) 5/1/2006 5/29/2006 6/5/2006 6/12/2006 6/19/2006 6/26/2006 Sine Vibe TestInstall Radiators EMI Test Acoustic Test 7/3/2006 7/10/2006 7/17/2006 7/24/2006 7/31/2006 TVAC Prep TVAC Open Door 8/7/2006 8/14/2006 8/21/2006 8/28/2006 TVAC Test Remove Radiators Wt & CG 9/4/2006 Ship I&T SVAC A. Borgland E. Charles W. Focke Sub-Total As Required 1 1 1 1 1 1 1 1 1 1 1 1 1 0 0 1 1 1 1 1 1 1 1 2 1 0 0 0 1 1 1 1 1 1 3 1 1 3 1 1 2 1 1 2 1 1 2 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 2 2 3 1 0 0 0 0 Mech/Thermal M. Campell B. Olson J. Ku J. Goodman J. Wang Sub-Total 3 3 1 3 2 1 1 4 0 0 0 0 0 0 DAQ J. Thayer G. Thayer Sub-Total System Engineering P. Hascall R. Baun R. Bright R. Bielawski Sub-Total 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 Management K. Fouts L. Klaisner D. Horn Sub-Total Integration and Test Presentation 8 of 12 1 0 1 0 0 0 0 1 0 1 1 0 1 1 0 1 0 36 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Environmental Test Staffing Summary SLAC Staffing at NRL 18 EMI Test Vibe Test Acoustic Test WT/CG TVAC Test Ship 16 14 Total FTE at NRL 12 10 8 6 4 2 Integration and Test Presentation 8 of 12 00 6 4/ 2 9/ 20 06 8/ 28 / 20 06 21 / 8/ 20 06 8/ 14 / 00 6 8/ 7/ 2 20 06 7/ 31 / 20 06 7/ 24 / 20 06 17 / 7/ 20 06 10 / 7/ 3/ 20 06 7/ 20 06 6/ 26 / 20 06 19 / 6/ 20 06 6/ 12 / 00 6 5/ 2 6/ 5/ 29 / 20 06 0 37 GLAST LAT Project May 25, 2006: Pre-Environmental Test Review Summary • The LAT baseline performance has been demonstrated post shipment to NRL. • The LAT instrument as-built configuration is in accordance with current engineering. • Documentation, preparation and pathfinding for handling and configuring the LAT for Environmental Test have been completed. • All EGSE and MGSE has been identified and its use has been demonstrated. • LAT I&T has completed the necessary preparation to begin the LAT Instrument Environmental Test. Integration and Test Presentation 8 of 12 38