2006_WS_BattleOfTheBulge - Association for Software

advertisement

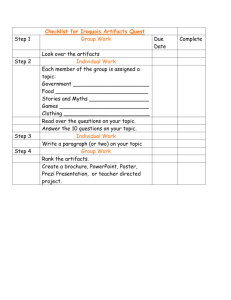

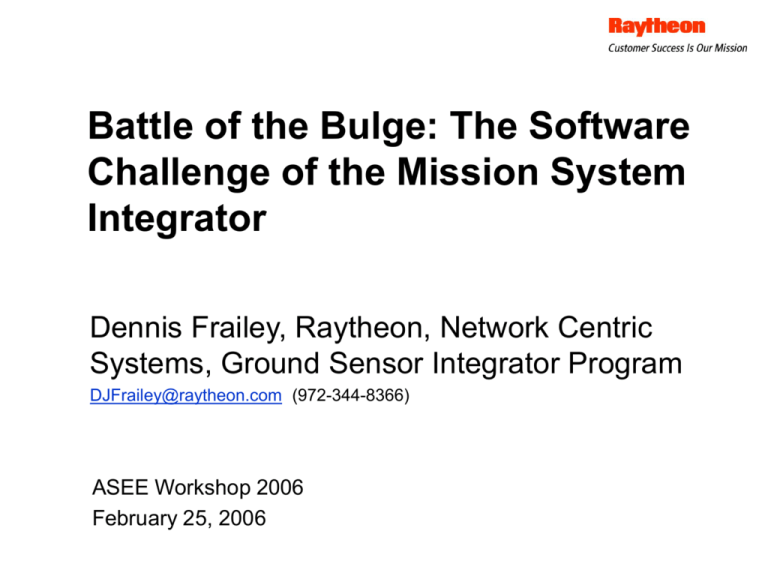

Battle of the Bulge: The Software Challenge of the Mission System Integrator Dennis Frailey, Raytheon, Network Centric Systems, Ground Sensor Integrator Program DJFrailey@raytheon.com (972-344-8366) ASEE Workshop 2006 February 25, 2006 Program Tiers - What is a Mission System Integrator? >$300M Mission System Integrator >$100M Complexity >$100M LSI MSI System $50M-$100M Subsystem $1M-$50M Component Tier 5 Tier 4 Tier 3 Tier 2 Tier 1 Value ($) 2/25/2006 Slide 2 Communication Flow Our Customer (Lead System Integrator) Our Internal SW teams GSI (Mission System Integrator) Ultimate Customer (US Army) GSDs GSDs GSDs GSDs(Our Suppliers) 2/25/2006 Slide 3 Sensors, Suites and Vehicles Sensors (what our suppliers do) EO 2 Suites (what we do) S1 Dev1 Dev3 V1 V2 Dev2 Radar 1 Vehicles (our customers) S2 V3 V4 Dev4 EO 3 S3 EO 1 S4 Detector S5 V5 V6 V7 S6 SPEC Sensors S7 V8 V9 2/25/2006 Slide 4 Software Development and Management SW Development SW Oversight and Management Delivery to Vehicles GSI Software Team (Integration into Suites) Simulator Emulator Simulator Emulator Sensor Sensor GSD #1 GSD #2 Simulator Sensor Special System Models Lab Tools GSD #n V&E IPT I&T IPT Emulator … Simulators Each GSD produces multiple products containing software. Wrapper Wrapper Sensor Suite Control Make/Buy The GSI produces or acquires other software needed for integration. 2/25/2006 Slide 5 Expanded Risk/Opportunity Management All Programs MSI Additions Honest assessment of risk or opportunity with a solid quantitative impact (technical, schedule, cost) Integrated risk/opportunity plan with all program partners Integrated risk/opportunity assessment and tracking Mitigation plans resourced in program execution plan with customer buy-in + Multi Level Risk/Opportunity Boards with elevation process Automated Tool (ARM) that allows easy integration from all levels is essential List of Watch Items with well defined trigger points Balanced opportunity plan 2/25/2006 Slide 6 Expanded Customer Relations All Programs MSI Additions Honest timely communication Multi Level communication plan is critical No surprises Mutual Problem Solving Constant focus on Performance Assessment Quality Presentation Collaborative execution environment is valuable + Lower Level customer / contractor communication up to the top levels are aligned (good and bad) Open forum to address bureaucracy issues (One Team Partner Council) Peer partner relationships are equally important Collaborative execution environment is mandatory 2/25/2006 Slide 7 Expanded Change Management All Programs MSI Additions Baseline definition and management Requirements Contract SOW Interfaces Architecture and Standards Traceability interfaces and impact analysis Balanced Cost/benefit process for derived requirements + Automated workflow configuration management processes and tools Streamlined Holistic Multi Level decision process Balanced Cost/benefit Process Horizontal / Vertical Robust Engineering Review Boards and Configuration Control Boards 2/25/2006 Slide 8 Expanded Process Requirements MSI Additions All Programs Integrated Process CMMI Six Sigma Local Tailoring of Processes + Need processes that reflect MSI type program i.e. multi-level integration, multi-level requirements management, multi-level risk management, multi-level configuration control, and many suppliers. 2/25/2006 Slide 9 Why This Isn't Enough Gaps: Our processes assume one program, not multiple tiers of programs 6 sigma CMMI Integrated Product Developmen t System Process for Improvement How we do business Standards and Best Practices 2/25/2006 Slide 10 Gap Analysis Process MSI Requirement s Organizationa l Processes Prioritized List of New Artifacts Needed for an MSI Program An MSI would need many new artifacts in addition to the organizational processes already in place – Work Instructions, Tools, Procedures Well established estimating process use to determine the development costs The Bulge MSI Process Improvement Project 2/25/2006 Slide 11 Some Examples of New Work Instructions Needed How to Review and Evaluate Supplier Bids, Plans, Deliverable Documents and Software How to Control Changes in a Multi-level Hierarchy How to Manage Software Suppliers How to Establish Architectural and Design Standards for Multiple Suppliers that Enable Effective Integration but Allow Each Supplier to Use its Own Processes How to Define Metrics that Each Supplier can Provide within their existing process and can be Consolidated into Meaningful Assessments of Supplier and Program Health How to Assess “ilities” (safety, supportability, maintainability, etc.) at an overall system level when each supplier has its own systems for defining these things. How to gain maximum benefit from Reuse when the existing reusable assets are highly diverse 2/25/2006 Slide 12 Example: Change Management Consider the Possibilities … Sensors (what our suppliers do) EO 2 Suites (what we do) S1 Dev1 Dev3 V1 V2 Dev2 Radar 1 Vehicles (our customers) S2 V3 V4 Dev4 EO 3 S3 EO 1 S4 Detector S5 V5 V6 V7 S6 SPEC Sensors S7 V8 V9 2/25/2006 Slide 13 CMMI Experience Gave Us Leverage Estimation Process Continuous Improvement Ingrained in the Organization Configuration Control Infrastructure Templates for Work Instructions • Our CMMI and Process Peer Review Process and Tools for Work Instructions Metrics Baseline foundation gave us many tools to approach this challenge • They provided a baseline approach for metrics, work instruction development and review, configuration control, estimation and improvement • Thus we were able to focus on Metrics Collection, Analysis And Storage solving the problem rather than defining the approach 2/25/2006 Slide 14 Multi-Year Approach • We employed a phased approach to tackling this problem First identify and prioritize emerging program needs Then develop new, organization-level artifacts Finally, tailor those to program needs • Artifacts arrive “just in time” to meet program needs Program Needs Program Needs New Org Artifacts Year 1 Program Needs New Org Artifacts New Org Artifacts New Program Artifacts New Program Artifacts New Program Artifacts Year 2 Year 3 Year 4 2/25/2006 Slide 15 Future Our organizational processes are enriched as we flow MSI Improvement Project artifacts back into the organizational process. Organizational Process Enhancements MSI Process Improvement Project Enhanced Integrated Product Developmen t System 2/25/2006 Slide 16 Questions 2/25/2006 Slide 17 Biography Dennis J. Frailey Dennis J Frailey is a Principle Fellow assigned to the Future Combat Systems Ground Sensor Integrator team in Plano, TX. He is currently responsible for many roles on the program such as development and maintenance of the software development plan, chair of the software configuration control board, and sundry duties associated with selection and evaluation of software suppliers. Dr. Frailey, who earned a PhD in Computer Science from Purdue in 1971, has been with Raytheon (and previously with Texas Instruments) for 32 years. His career includes positions ranging from college professor to developer of real-time operating systems, scientific applications, and user interfaces to speechwriter for corporate executives to software process improvement specialist. He has been head of an SEPG and was the software lead on numerous proposals. Dennis is an ACM Fellow and Distinguished Lecturer; an IEEE Senior Member and Distinguished Visitor; and an Engineering Accreditation Evaluator. He served as vice president of ACM, conference chair and program chair for over two dozen major computing conferences, and is the author of over 100 published technical papers. In addition, he serves as an adjunct professor at Southern Methodist University, UCLA and the University of Texas at Austin. Dennis has spoken at many conferences, including keynote addresses at the SIGADA national conference, the Conference on Software Engineering Education, the Euromicro Software Engineering Workshop, and several regional conferences. Dennis can be reached at: 972-344-8366 or DJFrailey@Raytheon.com 2/25/2006 Slide 18