03. Water Management and Recycling Practices

IPPTA Zonal Seminar

Ahmedabad

6 th & 7 th August 2015

Water Management and Recycling Practices

ITC Limited,

Paperboards and Specialty Papers Division,

Unit : Kovai

Contents of the Presentation

1. Introduction

2. Approach to Water Conservation

3. Case studies

4. Sustenance & Improvements

5. Results

6. Conclusion

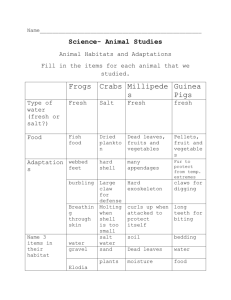

Process Flow

Waste

Paper

Waste

Paper

Waste

Paper

Fuel

Emission:

SPM

<30ppm

Water from

River

Water

Treatment

DM Plant

Cogen

8MW

Windmill

7.5MW

Condensate

Pulper

Screen

Centricleaner

Hot disperser

TL wire

Steam

Pulper

Pulper

Screen

Centricleaner

Hot disperser

Screen

Centricleaner

Hot disperser

Stock

Preparation

Petax

Filter

FL wire

BL wire

Press

&

Temsec

Treated

Effluent

Reuse

ETP

Dryers,

MG,

Calender

Coater

Rewinder

Finishing

House c h t a s p i

D

Board machine

TSS

<30ppm

Treated Effluent for Irrigation

3000

1900

375

250

475

Water Treatment

From River Plant Water Balance

500

1400

395

Stock

Preparation

440

4905

Clarifier

EL -290

Board

Machine

1320

2490

KROFTA

1960

3735

45

Petax

585

650

1840

ETP

1630

EL -325 EL -30

DM plant

335

Boiler

10

40

70

20

230

15

160

Cooling tower

Outsiders

Gardening

EL -230

20

100% Water Consumption is metered

Drinking & cooking

40

STP 1 & 2

Domestic

Fire system water

EL –Evaporation Loss Water meters

1650

Irrigation

•

Eliminate Waste

• Enhance Speed

• Efficient Value Streams

• Lower Inventories

• Reliable and effective Supply Chain

• Total Employee Involvement

• Continuous Improvement

• Process, Asset & People Care

• Sustain Gains

Organization WORLD CLASS

ZERO LOSSES

Lean Organization

PSPD Level

Unit Level

Divisional Management Committee

Unit Steering Board Plant Facilitator USB

EHS Pillar Team

Pact Pillar Team

Office Pillar Team

Quality Pillar Team

Planned Maintenance Pillar Team

HR Pillar Team (Skill Development)

Pillar

Teams

Area Level

Area Effectiveness Team

Shift Level

Utilities

Board machine

Stock

Finishing House

Engineering

Quality

Finance

Materials

Out side Sheeting

Personnel & Welfare

Admin

Information system

Customer Service Cell

Service Effectiveness Team

Process & Asset Care Teams - 16

16 PACTs

Approach for Water Conservation

PACT/AET -

Kaizens

Idea

Generation

Internal/TEI

Water Audits

Campaigns/

Posters

Training

EMS/EMC

Review

Training

External Seminars

Competitions

7

Water Conservation Technique

4 R – Technique

Reduce

Recycle

Reuse

Recharge

Water Conservation

“Reduce”

Reduce

Water Conservation

“Reduce”

The activities involved under this category are;

•To identify the required sizes of nozzles, showers and pipelines with respect to sizes and required numbers

•To identify the auto control loop required locations with respect to operational parameter requirements

•Optimization of chemical usage

•To identify areas of Water Wastage i.e., Leakages

•To identify the areas where the requirement of water is less and the actual

usage is high, especially utility purposes e.g, Toilets, Canteen, Gardening etc.

10

Water Conservation projects

“Reduce”

Key initiatives

5

6

7

8

9

3

4

1

2

S.No

Title of Water Saving project implemented

Level Control for Top liner back water chest

Optimization of back liner wire edge cleaning shower

Optimization of 4 number of Press part LP shower

Temperature control loop for vacuum seal pit make up fresh water

Reducing sealing water in condensate vacuum pump

Replacing all LP showers in wire part with new one

Optimizing Top liner backwater in system

Year of

Implementation

Annual Water

Savings

Investment

Made m 3 Rs. Lakhs

Jan-08 15,840 0.38

Jan-08

Jan-08

Feb-08

Jul-08

Jan-09

Jan-11

15,840

79,200

95,040

23,760

33,000

21,250

0.15

Nil

1.75

Nil

4

0.22

Optimizing RCC tower cleaning water Dec-11 12000 Nil

Ordinary water tap replaced with Foam tap May-13 4200 0.28

11

Temperature Control Loop for

Vacuum Seal pit make up

Case Study:1

Past Scenario:

Vacuum pump sealing water used to get make up with fresh water on continuous basis to avoid higher temperature so as to control scaling related issues.

Present Scenario:

A Temperature Indication and control system along with control valve has been introduced in the loop which reduced the fresh water make up directly.

Vacuum Pump

Fresh water

Flume Pit

Fresh water

Project Summary:

Vacuum Pump

TIC

Fresh Water Savings 95040 M 3 /Annum

Flume Pit

Investment 1.75

Lakhs

12

Optimizing Top liner Backwater

System

Case Study:2

Past Scenario:

Top liner Back water goes to Silo I and Silo II then to Save all supply chest where all three layer water stored and recycled for further usage.

Present Scenario:

TL Silo

I

Top liner Silo II water is now diverted to one additional storage tank and taken to stock preparation for pulper dilution purposes which avoid fresh water make up in stock preparation

TL Silo

Project Summary:

I

TL Silo

II

TL Silo

II

Fresh Water Savings

Investment

21250

0.22

M 3 /Annum

Lakhs

Save all supply

RCC

To Stock

T/L

Storage tank

Save all supply

RCC

To Stock

TL Make up in

Stock

13

Water Conservation

“Reuse”

Reuse

Water Conservation

“Reuse”

The activities involved under this category are;

• Identifying potential area of replacing Fresh Water with back Water

• Identifying locations where fresh water is used for floor cleaning

• Identifying excess water availability for storage and reuse

• Identifying major ‘sealing water’ source to reuse

• Exploring usage of all ‘blow down water’ for some processes

15

Water Conservation projects

“Re-use”

Key Initiatives

15

16

4

5

10

11

12

13

14

8

9

6

7

1

2

3

S.No

Title of Water Saving project implemented

Top liner tray water diverted to top liner silo

Reusing main condensate vacuum pump outlet water in process

Reducing & reusing water consumption by providing logic control in dilution systems

Reusing sump pit water & pulp in process

Reusing main condensate vacuum pump sealing water in process

Reusing of Effluent water to ETP Dilution & internal cleaning

Reusing Save all and Recovered chests excess water

Year of

Implementation

Mar-08

Annual Water

Savings m 3

11,880

Mar-09 23,760

Oct-09

Dec-09

Jan-10

Mar-10

Dec-10

12,000

39600

12960

9600

39,450

Reusing of hydrant system run check - drain water

Re using sealing water from coater section

Oct-10

Feb-11

600

8400

Re using m/c base wire pit section water into Filler silo tank

Effluent drain water collected in new SS tank and reused

Top liner Silo - II overflow collected and reused

Chest no -5 overflow to excess water tank

Top liner Krima Disperser sealing water reused

Back water in place of Fresh Water used for Floor cleaning in board machine

Drum Pulper Liquid cyclone drain water reused

Oct-11

May-12

Sep-12

Dec-12

Dec-13

Sep-13

Dec-13

330000

87500

262500

105000

15750

7000

17500

Investment

Made

Rs. Lakhs

0.15

0.1

Nil

1

0.2

2.5

1

-

4

0.5

0.18

0.35

Nil

Nil

-

1.75

16

Reusing Save-all and Recovered fiber chest excess water

Case Study:3

Past Scenario :

Filtrate waters from save-all supply and recovered fiber chest overflow sent to ETP whenever pump is having issue and imbalance in system till steady state is reached.

Present Scenario:

– Overflow line provided to a collecting chest and being pumped to back water supply tank.

– This has decreased fiber loss, and increased reuse of water in the plant.

Project Summary:

Fresh Water Savings

Investment

39,450

0.35

M 3 /Annum

Lakhs

Reusing Save-all and Recovered fiber chest excess water

Excess water chest

Save all Supply chest

Reusing Sump pit water and pulp in process

Case Study:4

•

Past Scenario:

Filtrate waters from middle liner systems, back liner systems and top liner poire systems washings, spillages, hydra screens etc from six meter, zero meters of stock preparation containing water, pulp and plastics are being collected in a sump and pumped to ETP

Present Scenario:

Collected water is being diverted to two pulpers.

First it is pumped to the plastic separating screens and then to the pulper.

This has decreased fiber loss, plastic load to ETP and increased reuse of water in the plant.

Project Summary:

Fresh Water Savings

Investment

39,600

1.0

M 3 /Annum

Lakhs

Reusing Sump pit water and pulp in process

Drum pulper Liquid cyclone water Re-use

Case Study:5

Past Scenario :

• Drum pulper Elutriation water used to go to sand separator and then after separating dense particle, water drained.

Before

Liquid cyclone

Present Scenario:

• After sand separator a collection tank provided with raised bottom and then the water is now taken to middle layer cloudy water tank for further use.

Project Summary:

Mid Liner

Cloudy water tank

To drain

After

Sand Separator

Liquid cyclone

Fresh Water Savings

Investment

1750

1.75

M 3 /Annum

Lakhs Collec tion tank

Sand Separator

21

Krima Disperser Sealing water Re-use

Case Study:6

Fresh water

Past Scenario :

• Fresh water is used to cool the lubrication system in Krima hot disperser of both Top liner and Bottom liner. The fresh water then was drained.

Cooling

Disperser

Lubrication

Before

Present Scenario:

• Small funnel was provided at both outlets of cooling system and water is collected and stored along with screen dilution water for further usage .

Disperser

Lubrication

Drain

Fresh water

Cooling

Disperser

Lubrication

Disperser

Lubrication

Funnel

After

Project Summary:

Fresh Water Savings

Investment

15750

0.50

M 3 /Annum

Lakhs

Screen

Dilution tank

22

Water Conservation

“Recycle”

Recycle

Water Conservation

“Recycle”

The activities involved under this category are;

• Identifying the areas of excess back water availability which can be

treated/processed for further usage in the process

• Upgrading water treatment facilities to enable recycling of waste water

• Exploring the usage of ETP treated water in process operation

• Exploring Best Available Technology (BAT) for maximum recycling of waste water

24

Water Conservation projects

“Recycle”

Key initiatives

8

9

10

4

5

2

3

6

7

S.No

1

Title of Water Saving project implemented

Year of

Implementation

Annual Water

Savings m 3

Investment

Made

Rs. Lakhs

New shell and tube heat exchanger installed in place of plate type heat exchanger to improve the condensate recovery

New ETP to treat the Top liner and coating separately

Fiber Recovery system

Reusing fiber recovery tank water by providing logic control

Mini press installation

Chest 5 & 7 fresh water make up reduction by using clarifier water

Filler Line KROFTA Clarifier Capacity Upgrade

ETP Treated water used in PETAX filter

Accept in place of Fresh water

Top Wire Shower Fresh water replaced with

PETAX water

Fill Less Cooling tower for Vacuum Flume water

May-08

Nov-08

Aug 2009

Feb-12

Jun-12

Jun-13

May-14

Jun-14

Mar-15

Mar-15

33,000

1,75,000

43000

182500

87500

52500

132000

52500

35000

58800

3.2

25

-

7.1

20

5

Nil

1

0.53

48

25

Fill Less Cooling Tower for Vacuum

Flume water

Case Study:7

Past Scenario:

Vacuum pump sealing water used to get re-circulated with temperature controlled fresh water make up.

Fresh water

Present Scenario:

Fill Less

Cooling tower

(-10 0 C )

A new Fill less cooling tower has been introduced to recycle the flume pit water after reducing temperature which avoid fresh water make up. The freshwater make up at cooling tower is relatively negligible.

Project Summary:

Fresh Water Savings

Investment

58800

7.1

M 3 /Annum

Lakhs

Fresh water

Vacuum Pump

Flume Pit

New

Old

26

ETP treated water Recycling in Stock Preparation

Case Study:8

Past Scenario:

ETP treated water was taken to irrigation to our own land. The water quality was further improved after installing Equalization tank.

Present Scenario:

Disc Filter introduced to further improve the water quality. SS pipeline from ETP to Secondary Fiber Treatment plant was laid and an additional filter was installed before SFT.

The water is taken to SFT for screen dilution purpose which replaced freshwater make up .

Project Summary:

Fresh Water Savings

Investment

52500

25

M 3 /Annum

Lakhs

27

Before

ETP treated water Recycling in Stock Preparation

After

ETP

Secondary

Clarifier

ETP

Secondary

Clarifier

600

M3 / Day

To Process

Disc Filter

Outlet Tank

Irrigation

2200

M3 / Day

Outlet Tank

Irrigation

1600

M3 / Day

Recycling fiber recovery tank water by providing logic control

Case Study:9

Past Scenario :

Pulping water for Drum pulper was taken from

RCC tower, hence fresh water used to get make up

Present Scenario:

Fiber recovery tank over flow recycled to drum pulper pulping with logic control

Project Summary:

Fresh Water Savings

Investment

182500

Nil

M 3 /Annum

Lakhs

29

Recycling of process waste water with

Mini press installation

Case Study:10

Past Scenario :

• In Secondary Fiber treatment (SFT) plant, fiber with low consistency gets rejected at various stages of screening and centri-cleaning. These rejects has high water content and drained to ETP stream.

Present Scenario:

• Three Mini press installed at rejection stage to handle and recover fiber and waste water

Project Summary:

Fresh Water Savings

Investment

87500

1.0

M 3 /Annum

Lakhs

30

Before

Recycling of process waste water with

Mini press installation

Pulping

Pulping

Screen rejects &

Centri cleaner rejects

Screen rejects &

Centri cleaner rejects

ETP

Drain

After

ETP

Drain

Hydra

Screen

Fiber & Plastic Rejects

Collection tank

Waste water to reuse

Reject to Boiler

Water Conservation

“Recharge”

Recharge

Water Conservation

“ Recharge “

The activities involved under this category are;

• To recharge the rainwater to the ground to increase the water table.

• Though the recharge is not directly reducing water usage, it is the key factor

to save water for near future and for the benefit of the society in large.

• The implementation is done under two category; a) Internal / Inside mill b) External /Surrounding mill

33

Water Conservation projects

“Recharge”

Inside mill

• 83.2% of roof tops are are re-charged and maintained

• The potential of this saving is about 10,040 M 3 /Annum.

• In addition pave and unpaved area also covered.

Roof Area

SL.No

Location Type of Roof Area-Sq Mtr

1 Finishing House & Godown GI Sheet

2 Board M/c & Stock area GI Sheet

3 Pulp Godown

4 Inside Paper yard

GI Sheet

GI Sheet

5 Coal Godown

6 New Waste paper yard

7 A/c Drives Building

8 Boiler Turbine Hall

GI Sheet

GI Sheet

8550

7560

1500

9828

2992

5757.5

RCC 372

Precast Slab 1048.08

9 Reel Godown

10 Super Calander Area

11 General Stores

12 Capplant

13 Workshop

14 Time office Building

15 Training Hall

16 Bachelor Hostel

17

Drum Pulper & Disc Filter

Build

18 ETP Building

19 New Fuel Shed

GI Sheet

Asbestos

Asbestos

Asbestos

Asbestos

RCC

RCC

RCC

GI Sheet

RCC

GI Sheet

1168.8

421.26

1010.5

705

1008

260

145.2

360

384

168

1704

44942.34

Rain Water

Recharge

Provision

Yes

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

%

2.2

0.6

0.3

0.8

2.6

0.9

2.2

1.6

19.0

16.8

3.3

21.9

6.7

12.8

0.8

2.3

0.9

0.4

3.8

Area of Roof-top with

Rain water Recharging

83.2%

34

Water Conservation projects

“Recharge”

Outside mill

The surrounding areas are selected based on survey by experts and various type of water conservation infrastructures have been developed. The unit involves itself in Ground Water augmentation beyond the fence through;

•Farm ponds

•Percolation ponds

•Check Dams

•Contour bunding

•Drip irrigation

S.No

Recharge

Infrastructure

1 Farm Ponds

2 Percolation Ponds

3 Check Dams

Numbers

Benefit villages

45

9

7

18

9

5

Benefit area

(Acres)

12

161

194

35

Green Belt Development

160000

140000

120000

100000

80000

60000

40000

20000

10150

0

29076

47128

Cumulative Tree Population

84399

91787 91787

104723

117533

142471

147021 147271

Water Saving Kaizens

37

KAIZEN – By Water & Waste water Team

Bench marking

39

Benchmarking – Specific Water

Consumption

30

25

20

15

10

5

0

Source: NPC

25

19

9,8

CPCB National

CPCB National ITC Kovai

ITC Kovai

Sustenance & Improvements

41

Review : Sustenance & Improvements

• Consumption at all consuming points are captured in DCS

• Daily area wise fresh water consumptions are monitored

• Water consumptions reviewed, variance analysis carried out & corrective actions planned

- Daily AET’s meetings

- Weekly Energy Management Cell review

- Monthly review by Unit Steering Board

- Designated Water Manager

• Regular Training on water conservation

AET Activity Board

Daily trend of Raw Water Consumption being tracked

43

Training Calendar and records

Topic : Water Clarification & Krofta

44

Awareness on Water Needs to

Stakeholders

45

World Environmental Day - Awareness

Environment protection Oath - employees

Environment protection Oath - Community

Awareness Rally

World Water Day - Awareness

Water Day celebration

Motivation for Best suggestions

Water conservation Oath

Celebration of Water Day

48

Involving Local Community in Tree plantation

Water - Posters

Knowledge Sharing

•

All innovative ideas and suggestion are shared across our units through lotus notes.

•

Quarterly review meeting across the units for sharing ideas and suggestion for improvement

•

Innovative ideas are shared with neighboring industries

•

Shared online in In-house Bhadra net across units

•

Best Energy Saving Kaizens are shared with unit level and rewarded for motivation.

•

Lean Express – Internal knowledge sharing

Magazine

Results

Water Consumption (M3/MT)

9

8

7

12

11

10

16

15

14

13

14,66

2011-12

13,72

2012-13

12,44

2013-14

9,84

7,74

2014-15 2015-16 Plan

• The unit achieved 33% reduction in last three years and about 65% since inception.

• Innovation, timely up-gradation of new technology, employees involvement under TPM and top management commitment are the key factor to achieve the excellence in water Management.

Conclusion

Mill approach towards continual improvement through Total

Employee Involvement (TEI) resulted in achieving Excellence in water management and also helped the unit to become the first paper mill in India to receive the CII – Green Co-Platinum rating – the highest rating in the country for meeting the world class standards in sustainability

Thank you