2_Modeling_Fundamentals_(BEMWork_DC_01-06-11

advertisement

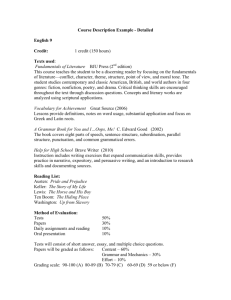

MODELING FUNDAMENTALS IBPSA - USA 1 IBPSA-USA SHELL GEOMETRY GENERAL CONCEPTS 2 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA SHELL GEOMETRY USE OF ENERGY MODELING WIZARDS In what cases are energy modeling wizards most useful? After making edits in main program Initial Model Creation •Geometry and zoning •Define all system types that may be used Significant Rezoning or Major Geometric Changes •Copy and paste into input files to retain what you have changed outside of the wizard Test or Copy Setups for Complicated Tasks •Demand Control Ventilation •Skylights with plenums •Slab insulation •Breaking out fan power 3 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA SHELL GEOMETRY RULES OF THUMB FOR SIMPLIFICATION Simplify REALITY • • ENERGY MODEL Thermodynamically, only (3) things matter for modeling heat transfer surfaces 1. Area 2. Orientation 3. Tilt Total volume matters IF infiltration is specified in ACH ASHRAE 90.1-2007 Appendix G • Table G3.1, #5 Building Envelope, Exceptions (a) and (b) – – Uninsulated assemblies Exterior surfaces whose azimuth, orientation, and tilt differ by < 45˚ 4 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA SHELL GEOMETRY RELATIVE PLACEMENT OF SURFACES What Matters •Area •Orientation •Tilt Note: With daylighting the building form is important 5 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA SHELL GEOMETRY RELATIVE PLACEMENT OF SURFACES Annual Energy by Enduse Annual Energy by Enduse 6 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA SHELL GEOMETRY GEOMETRY INTERFACES SketchUp Plugins CAD (dwg files) • Open Studio for EnergyPlus • IES Virtual Environment • 2-D CAD plans may be imported into energy modeling programs • gbXML streamlines the transfer of building information to and from engineering models 7 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA SHELL GEOMETRY GEOMETRY INTERFACES Building Information Modeling (BIM) • Generating and managing building data • Well developed for architecture, needs improvement on MEP side • Early development phase for energy modeling Goals Barriers • Automatic model generation from 3D renderings • Architects/engineers will specify “properties” of materials and equipment for automatic modeling • BIM needs work in some segments (i.e. electrical engineering) • Danger of “black box” energy modeling 8 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA SHELL GEOMETRY ASHRAE 90.1 APPLICATIONS The number of floors and conditioned floor area shall be identical. Total gross areas of exterior, opaque surfaces shall be identical. Vertical fenestration areas for the baseline shall equal the smaller of: • the proposed design, OR • 40% of gross above grade wall area The baseline building shall be modeled so that it does not shade itself. Glazing shall be distributed on each face of the baseline building in the same proportions in the proposed design. 9 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA EFFECTIVE ZONING GENERAL CONCEPTS Number of zones is proportional to complexity of energy model Aggregation of rooms into zones: significant impact on energy use and overheat prediction Especially with large multizone systems Zoning in simulation models can differ from actual HVAC zoning Energy model zones are abstract # of model zones < # of HVAC zones 10 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA EFFECTIVE ZONING CRITERIA FOR ZONING AN ENERGY MODEL Usage • All rooms should have similar internal loads and usage schedules Temperature Control • All rooms should have the same Tstat schedules Solar Gains • Perimeter zones with windows: Min. one zone for each compass direction • Unglazed exterior zones can be combined • Consider shading! Perimeter or Interior Location • 12-15’ perimeter zones often require winter heating • Core spaces can require year round cooling Distribution System Type • Combine rooms served by the same type of distribution system (i.e. fan coil units) 11 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA EFFECTIVE ZONING SPACES VERSUS THERMAL ZONES Thermal Zone = area controlled by a single thermostat Energy Modeling – Typical one zone for each space – Hourly loads are calculated based on an energy balance of the space. – At the thermal zone level, the loads from the spaces are considered in conjunction with the temperature set-point and HVAC operating schedules to determine the zone load. 12 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA EFFECTIVE ZONING ZONE TYPES WITHIN AN ENERGY MODEL Conditioned • Space is heated or cooled Unconditioned • Space is neither heated nor cooled • Examples are false ceiling spaces not used as return air plenums, attics, crawl spaces and garages Plenum • Return air space • Atrium as return plenum • Heat transfer within plenums 13 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA CONSTRUCTIONS OVERVIEW Types of Exterior Opaque (walls, roofs, Constructions slabs, underground walls, etc) Quick Interior (mass, air, layers, etc) Exterior Glazed Parallel Path Calculations for a Stud Wall vs. Delayed 14 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA CONSTRUCTIONS EXTERIOR (DELAYED) CONSTRUCTIONS - OPAQUE Material Properties Layers • Materials are “layered” from outside to inside • Outside and inside air films • Conductivity • Density • Specific Heat • Thickness Constructions • Layers determine U-value • Surface Roughness • Solar Reflectivity What about construction assemblies with parallel heat transfer paths? 15 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA CONSTRUCTIONS PARALLEL PATH CALCS FOR WOOD STUD WALL ORNL Online Calculator Wall Section R-Value of Insulated Section R-Value of Stud Section Typical Stud Wall = R-Value (brick) = R-Value (brick) Overall Weighted R-Value of Wall Assembly = ASHRAE 90.1 Appendix A + + ( R-Value (Sheathing) R-Value (Sheathing) 0.91 x + R-Value (Insulation) + R-Value (Insulation) R-Value of Insulated Section ) + R-Value (Gyp. Board) + R-Value (Gyp. Board) + ( 0.09 x + R-Value (Inside Air Film) + R-Value (Inside Air Film) R-Value of Stud Section ) 16 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA CONSTRUCTIONS SLAB HEAT TRANSFER Do you need to perform outside calculations? Slab Heat Transfer Underground Surfaces: How to get a better underground heat transfer calculation in DOE-2.1 by Fred Winkelman 1) Choose F-factor from a series of tables 2) Calculate the exposed perimeter and area of slab. Use equation Reffective = A / (F*Pexposed) 3) Set Ueffective = 1/Reffective. 4) Create a material with Reffective 17 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA CONSTRUCTIONS GLAZING CONSTRUCTIONS Glazing Properties • Center of Glass U-value • Solar Heat Gain Coefficient (SHGC), OR Shading Coefficient (SC) • Visible Light Transmission (VLT) • Light to Solar Heat Gain Ratio (LSG) Common Pitfall: Outside Air Films 18 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA CONSTRUCTIONS GLAZING CONSTRUCTIONS Includes Spectral Data: varies SHGC and Tvis with solar angles 3 Options for Modeling Glazing Simplified Library Glazing Window 6 (LBNL) SHGC = solar heat gain coefficient Tvis = visible light transmission 19 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA CONSTRUCTIONS WINDOW FRAMING 2 Options for Modeling Framing Include framing effects in glazing construction • Model large bands of glass, OR • Model windows individually Common Pitfall: Window 6 does not include framing when you export files Model framing explicitly • Works well with Window 6 option • Use window multipliers Common Pitfall: Modeling large bands of glass 20 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA LIGHTING OCCUPANCY & PLUG LOADS GENERAL CONCEPTS Peak Power and Occupancy • Total watts of all connected power • Peak number of occupants • Can be input with density values Fractional Schedules • Daily/Weekly/Annual Occupancy Schedules • Hourly fractional multiplier for peak values • Daylight Dimming or Occupancy Sensors Fraction of Heat Gain to space • Assign proportional amounts of heat to space vs. plenum 21 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification LIGHTING OCCUPANCY & PLUG LOADS PEAK POWER AND OCCUPANCY IBPSA-USA PEAK values include all connected loads • • • • Electric Lighting (total fixture wattage) Emergency Lighting Plug loads Kitchen Equipment, Elevators, Servers, etc. Sources for Estimating Equipment Power Density and Peak Occupancy • • • • • ASHRAE 90.1 User’s Manual Title 24 Alternative Calculation Method (ACM) Manual COMNET (Commercial Energy Services Network) ASHRAE Handbook of Fundamentals ASHRAE 62.1 (Occupancy) Modeling Fundamentals Performance Rating Method Best Practices Inform Design 22 Measurement & Verification IBPSA-USA LIGHTING OCCUPANCY & PLUG LOADS - SCHEDULES • Just as important as peak values! • Unregulated by ASHRAE Std 90.1 Lighting 100% 90% 80% 70% 60% Wk 50% Sat 40% Sun 30% 20% 10% 0% 1 3 5 7 9 11 13 15 17 19 21 23 23 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA LIGHTING OCCUPANCY & PLUG LOADS - FRACTION OF HEAT GAIN TO SPACE Radiative (time lag) vs. Convective 24 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification LIGHTING OCCUPANCY & PLUG LOADS DAYLIGHTING Direct daylighting within energy model IBPSA-USA Daylight Specific Tool • Limited daylight simulation engine • Generally more accurate, but requires parallel model • Know the limits on the number of light bounces and interreflectivity • SPOT and Radiance can generate hourly electric lighting reduction schedules for import into energy models • Carefully specify controls 25 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification LIGHTING OCCUPANCY & PLUG LOADS EXTERIOR LIGHTING IBPSA-USA Exterior lighting is modeled separately from interior lighting Can be controlled via photosensors or with schedules HID vs LED 26 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification LIGHTING, OCCUPANCY & PLUG IBPSA-USA LOADS OVERESTIMATES OF PEAK EQUIP POWER Measured data vs. typical values used in industry Implications for Mechanical Equipment Sizing Name Plate Ratings vs Heat Gains for HVAC sizing Energy Models: Design Day Sizing Feature 27 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA MECHANICAL SYSTEMS OVERVIEW Gain and Losses: Lights People Internal equipment (e.g. computers) Building envelope (sun, outside temps) Ventilation/infiltration Q=Σ gains + losses + ventilation load Equipment Sizing Q = (1.08)*cfm*(MAT-SAT) air Q = 500 * ΔT * GPM water 28 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA MECHANICAL SYSTEMS COOLING AND HEATING LOADS Mechanical HVAC systems move energy from one space to another Cooling systems Reject heat to the outdoors via condensers/cooling towers Heating systems Deliver heat to the internal space k 29 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA MECHANICAL SYSTEMS PACKAGED & CENTRAL PLANT SYSTEM DIAGRAMS Central Plant supply fan compressor Water Side condenser Packaged System Air Side Modeling Fundamentals Performance Rating Method 30 Best Practices Inform Design Measurement & Verification IBPSA-USA MECHANICAL SYSTEMS PACKAGED SYSTEMS Energy Modeling Tip: Do not double count zones fan, Packaged systems can serve single or multiple compressor and condenser power Air-Cooled Condensers • Split DX systems • Package DX systems • DX computer room air conditioners (CRACs) WaterCooled Condensers • Dry coolers or closed-loop cooling towers • Cooling towers Evaporatively -Cooled Condensers • Direct evaporative package units • Indirect/direct evaporative package units GroundSource • Air heat pumps • Water heat pumps Heating Systems • Electric baseboard heaters • Oil and gasfired furnaces 31 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA MECHANICAL SYSTEMS CENTRAL PLANT SYSTEMS Energy Modeling Tip: Pay attention to pump power Central plant systems typically serve multiple zones and part load curves Chilled Water Cooling Systems • Air-cooled chillers or closed-loop cooling towers serving chillers • Water-cooled chillers served by open-loop cooling towers • Evaporatively-cooled chillers Heating Systems • Central boiler plant • Steam boilers • Hot water boilers Distribution Systems • Air handlers with chilled water cooling coils and/or hot water heating coils • Fan coils • Radiators • Chilled beams / radiant panels 32 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA MECHANICAL SYSTEMS TERMINAL UNITS Standard VAV box with reheat coil Variable airflow Series fan-powered VAV box with reheat coil Constant airflow, fan always on Important Inputs • Min. airflow fraction – Fixed or scheduled • Thermostat type – Proportional vs. reverse acting • Terminal unit fan power Parallel fan-powered VAV box Variable airflow, fan on when reheat needed Reference: Advanced VAV Design Guideline, Appendix 8 How to Model Different VAV Zone Controls in DOE2.2 www.energydesignresources.com 33 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA MECHANICAL SYSTEMS FAN CURVES • Fan power = f(airflow) for VAV systems • “Canned” & custom curves Fan Curve Issues: • “Canned” VSD fan curves are often optimistic • If creating a custom curve, plot it and check it, set appropriate minimum value • ASHRAE 90.1 Appendix G specifies the curve to be used for VAV systems Source: DOE2.2 Volume 2 Dictionary 34 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA MECHANICAL SYSTEMS FAN CURVES – 90.1 APPENDIX G CURVE 100% 90% 80% 70% Std 90.1 App G VSD curve Fan Power PLR 60% 50% 40% 30% 20% DOE2.2 standard VSD curve 10% 0% 0% 20% 40% 60% 80% 100% Airf low Part Load Ratio Modeling Fundamentals Performance Rating Method Best Practices 35 Inform Design Measurement & Verification IBPSA-USA MECHANICAL SYSTEMS FAN CURVES – STATIC PRESSURE RESET CONTROL • Static Pressure (SP) Reset 90% No SP Reset 80% 70% Fan Power PLR – Continuously adjust pressure to lowest setting that provides adequate zone airflow – Simulate using fan curve 100% Good SP Reset 60% 50% 40% 30% 20% Reference: Advanced VAV Design Guideline, Appendix 5 10% Perfect SP Reset 0% 0% Includes fan curve coefficients 20% 40% 60% 80% 100% Airf low Part Load Ratio www.energydesignresources.com 36 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA MECHANICAL SYSTEMS CHILLER CURVES • Chiller performance model – Capacity = f(temp) – Efficiency = f(temp, part-load ratio) Elecin CapFullLoad EIRFull Load • Represent chiller types – Centrifugal, rotary, reciprocating… – Variable speed, multi-compressor… • Default vs. custom coefficients Reference CoolTools Chilled Water Design Guide. Chiller Bid and Performance Tool, (Excel spreadsheet). www.energydesignresources.com 1.0 at full load and rated temp. CAPf(T) EIRf(T) EIRf(PLR,dT) Issues Part load efficiency curve typically includes PLR: EIRf(PLR,dT) PLR EIRPart Load EIRFull Load (EIR = energy input ratio = 1/COP) 37 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA MECHANICAL SYSTEMS OUTSIDE AIR REQUIREMENTS • Significant implications for annual energy consumption • Energy Models: cfm/person OR cfm/sf OR cfm • PRM: same OA in Proposed and Baseline – Exception: demand control ventilation • Healthcare ventilation: Standard 170 • Exhaust requirements mandatory (section 6.5) ASHRAE 62.1 Ventilation Rate Procedure Indoor Air Quality (IAQ) Procedure Natural Ventilation 38 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA MECHANICAL SYSTEMS ASHRAE 62.1: VENTILATION RATE PROCEDURE Vbz = Rp*Pz + Ra*Az Vbz = cfm of outside air required in breathing zones Rp = outdoor airflow rate per person from Table 6-1 [cfm/person] Pz = the largest number of people expected to occupy the zone during typical usage [people] Ra = outdoor airflow rate per unit area from ASHRAE 62.1 Table 6-1 [cfm/sf] Az = occupied floor area of zone [sf] Used to determine design OA for energy models Calculating OA for multi-zone VAVs: huge energy implications At part-load/occupancy, the minimum OA intake flow ≥ Ra*Az. 39 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA MECHANICAL SYSTEMS ASHRAE 62.1: INDOOR AIR QUALITY (IAQ) PROCEDURE Design approach: Allows OA rates to vary if contaminant levels are below recommended levels Contaminant sources Contaminant concentration Perceived indoor air quality Mass balance analysis Occupant evaluation 40 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA MECHANICAL SYSTEMS ASHRAE 62.1: NATURAL VENTILATION PROCEDURE Prescriptive requirements Ceiling height Openable passages ≥ 4% of floor area 62.1-2010 requires mechanical ventilation UNLESS – OA passages are permanently open, OR – NO heating or cooling system is installed OR Engineered system with CFD modeling Controls required for coordination with mechanical ventilation systems 41 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA MECHANICAL SYSTEMS DEMAND CONTROL VENTILATION (DCV) • Ventilation airflow resets based on occupancy using CO2 sensors, timers, occupancy sensors or schedules • Higher energy savings for buildings with large occupancy swings Movie theaters, conference rooms • 10%-30% load reduction and 2-3 yr payback 42 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA MECHANICAL SYSTEMS ASHRAE STANDARD 55 Clothing Insulation Metabolic Rate Humidity Indoor Environment and Personal Factors Air Temp Air Speed Possible to assess within energy models that accurately simulate radiative heat transfer Radiant Temp 43 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA MECHANICAL SYSTEMS SPECIFIC ENERGY MODELING NOTES Common Energy Modeling Mistakes EER: break out fan power and compressor power Part load curves Altitude effects Auto-sizing Rated vs design conditions 44 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA UTILITY RATES TYPES OF CHARGES AND RATE STRUCTURES Monthly Charge •Fixed fee for providing energy services $35 per month Energy Charge •Unit cost for total quantity of energy consumed $0.06 per kWh Demand Charge Power Factor Charge Block Charge Time of Use Rate •Fee for highest or peak amount of energy used $7.53 per kW •Penalty for lower than optimum power factor $0.40 per KVAR •Unit charge based on different blocks of energy use or demand •Prices change during peak and offpeak times 0–350 kWh $0.06 per kWh 350–700 kWh $0.04 per kWh 700+ kWh $0.02 per kWh Peak Time $0.24 per kWh Off Peak Time $0.06 per kWh 45 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA UTILITY RATES TYPES OF CHARGES AND RATE STRUCTURES Energy Charge Demand Charge Block Charge Block 3 Block 2 Block 1 Summer (June-Sept) Time of Use Rate Winter (Oct-May) Peak 1pm–6pm (M-F) $0.16 per kWh Mid 11am–1 pm and 6pm–8 pm (M-F) $0.06 per kWh Off Peak All other hours, and holidays $0.02 per kWh All days All Hours $0.03 per kWh 46 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA UTILITY RATES ENERGY MODELING IMPLICATIONS ASHRAE 90.1-2007 Appendix G Applications • Same energy rates must be used for Proposed and Baseline • Use either actual utility rates or EIA state averages, except: – Actual utility rates must be used for purchased hot water, steam and chilled water • On-site renewables and site-recovered energy are NOT included with purchased energy 47 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA UTILITY RATES ENERGY MODELING IMPLICATIONS Case Study: Adam Joseph Lewis Center at Oberlin College • Project Goals ― Set an example for energy efficiency and sustainable design ― Net-zero energy building • • The project achieved significant reductions in total energy use However, no efforts were made to lower the peak demand, which resulted in a much lower energy cost savings 79% Total Energy Savings 35% Energy Cost Savings Utility Rates Can Be Crucial! 48 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA WEATHER DATA 49 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA WEATHER DATA ANNUAL WEATHER FILES • Necessary for annual energy and economic analysis • Useful for developing HVAC design strategies • Must include 8760 hours • Generally from sets of averaged data 50 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA WEATHER DATA ANNUAL WEATHER FILES TMY = Typical Meteorological Year • Data sets of hourly weather values for a 1-year period • Produced from 30 years of data • Representative of typical, rather than extreme, conditions (not suitable for sizing systems) • Intended use is for solar and building computer simulations 51 Modeling Fundamentals Performance Rating Method Best Practices Inform Design Measurement & Verification IBPSA-USA WEATHER DATA SOURCES FOR WEATHER DATA TEMPERATURES AND DEW POINTS • Design Conditions 40 30 – ASHRAE Handbook of Fundamentals 20 CELSIUS • Weather Statistics & Observations – National Climactic Data Center (U.S.) – Mesowest (Southwest U.S.) – Weather Bank (International) 10 0 -10 -20 1 2 3 4 Wind Direction Frequency Typical Meteorological Year 5 6 7 8 9 10 11 MONTH N Average Dry Bulb Temperature C • Annual Weather Data Average Dew Point Average Dry Bulb Temp F 360 15 30 – DOE-2 Website (TMY, WYEC, etc) – EnergyPlus Website (EPW, CSV) 45 345 330 40 35 45 315 30 25 60 300 20 15 75 10 285 ` 5 • International Weather Data – EnergyPlus Weather Source Data W 90 0 270 105 255 120 240 135 225 150 210 165 195 180 Modeling Fundamentals Performance Rating Method S Best Practices E Inform Design Measurement & Verification 52 1