Task. - Keswick textiles

advertisement

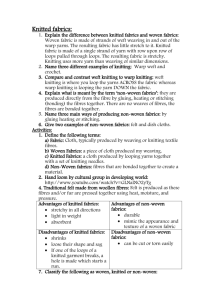

Knitted fabrics Task. Compare the structure of a knitted jumper with that of a polyester fleece jacket. • Describe the characteristics of each fabric. This tasks requires you to formulate your own response, the answer is not found in the text book! Weft knitted Weft knitted fabric is made from a single yarn, which is fed across the width of the fabric. • Weft knits are stretchy, they have a right and wrong side to the fabric. •They may be prone to laddering CAD/CAM knitting machine • These systems produce 90% of the knitted jersey, rib and jacquard fabrics that are used for T-Shirts, socks, underwear and knitwear. Properties of weft fabric • This kind of knitting produces comfortable, soft fabric that has a variable stretch depending on it’s structure. Types of production • Hand knit, can be used to produce one off, designer knits: jumpers of cushions Straight bar or fully fashion machine • Produces very high quality knitwear using natural fibres, especially wool, cashmere and merino wools. • http://vimeo.com/44718350 • http://vimeo.com/20955663 Single or double flat bed machines • Used to knit rectangular shaped panels for garments. • Very versatile when designing using CAD/CAM. Circular knitting machine These machines vary in size, depending on what they make. For example socks , jumpers or T-Shirts. These machines use CAD/CAM systems for continuous production, making single or double jersey fabrics. Make sure that you can identify which is which. Single jersey • A course is a horizontal row of loops, formed by the needles during one knitting cycle. • A wale is a vertical column of loops formed by a single needle. • The size of needle and the fineness of the yarn determines the density of the knit construction. • The combination of loop size, fineness of yarn, width and length of fabric determines the weight of the fabric. Single jersey properties The front of single jersey fabric is smooth. When cut it tends to curl. It has relatively low stretch in the width. Can be made from, cotton, cotton blends, acrylics, polyester, modal, viscose or wool. 2-5% elastane blends provide added comfort, crease resistance, enhanced drape and better shape retention Double jersey knits. • Is made on twp sets of needle beds in which the needles are opposite each other and work alternatively. • It takes two courses to make one row of loops on the front and back. • Double jersey fabrics are compact, stable, durable, keep their shape and are not very elastic. • They can be cut like woven fabrics. Double jersey end uses….. T-shirts, Underwear, Polo shirts, Sportswear, Skirts and leggings. Rib fabrics • Are made with two sets of needles which are staggered. • Alternate loops are knitted in the opposite direction to form vertical lines in the fabric. • Most popular construction is 2x2, where both sides of the fabric look the same. • The resulting fabric is very elastic widthways. Suitable for jumpers, waistcoats, underwear and socks. Jacquard fabric • Has a patterned design in 3 or more colours. • Its made by selecting needles to knit to a specified pattern using CAD systems. • In each succeeding course, the pattern is built up and if the colour isn’t needed it “floats” on the back. • There is a limit to the length of floats, can you think why> • Jacquard fabric isn’t very stretchy • This type of knitted fabric goes in and out of fashion for winterwear. Warp knitted • Fabrics are made on circular or • Straight CAD/CAM knitting machines. • Each loop of fabric is fed by it’s own separate yarn. Warp knitted fabrics • Are made on straight or circular knitting machines. • Each loop of the fabric is fed by it’s own loop of yarn. • The loops interlock vertically, along the length of the fabric. • Wrap knits are stretchy but do not ladder and can’t be unravelled. • Warp knit fabrics for example velour and terry are used for leisure and sportswear, furnishing fabrics and sheeting. Properties and uses • Warp knitted fabrics have some elasticity , do not ladder and they can’t be unravelled. • They can be cut like woven fabrics, yet they have a limited application for clothing. • They are mainly used for swimwear, leisure wear, linings, lacing, ribbons, trimmings. • They also have many industrial end uses, for example geo textiles Tricot • Is an industrial product warp knit, mostly using synthetic yarns. • Each yarn works in a zig-zag fashion and it’s used for gloves, lingerie and light weight furnishings Locknit • Is a combination between tricot and 2x1 plain knit stitches. • Made from a filament yarn. • The fabric is lustrous fabric used for linings and underwear. • The face of the fabric has vertical wales of loops and the back has characteristic zig-zags. Knitted velour – pile fabric • Is made from continuous filament fibres, has a raised fleecy surface effect, formed when the loops are cut and they stand up form the fabric, Polar fleece • Made from acrylic or polyester or nylon, is a double boucle knit, where the fabric is heavily raised on one side or the other. • It’s light weight, has a high bulk, it’s very breathable and very warm. • It’s used as an insulating fabric in leisure wear and sportswear. • NOT to be confused with a sheep's fleece Task. • Make a collection of knitted fabrics, used for a range of end uses. • Examine each fabric, try to identify the construction, is it warp of weft knitted? • How many colours? What yarn has been used? • Add your samples to the table for you Tech book, sketch construction and explain suitability for end use. Sample construction Yarn used End use