sathyabama university

advertisement

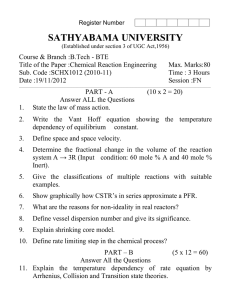

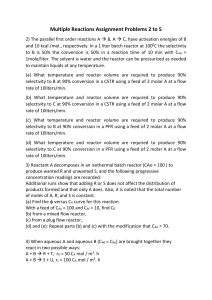

Register Number SATHYABAMA UNIVERSITY (Established under section 3 of UGC Act,1956) Course & Branch :B.Tech - P-CHEM Title of the Paper :Chemical Reaction Engineering – I Max. Marks:80 Sub. Code :619PT403-SCHX1026 (2007-08-09-10) Time : 3 Hours Date :05/05/2012 Session :AN ______________________________________________________________________________________________________________________ 1. PART - A (10 x 2 = 20) Answer ALL the Questions Define Molecularity and Order of reaction. 2. List out the merits of integral method of analysis of data over differential method of analysis. 3. What is a semi batch reactor? What are the advantages of this reactor? 4. Define space time and apace velocity. 5. What are the factors to be considered in the proper choice of reactors for a given reactor system? 6. The half life of first order reaction of A remains after 60 min? 7. Show how CSTR’s in series approximate a PFR graphically. 8. Define optimum temperature progression. 9. What is instantaneous yield and overall yield? A B is 10 min. What percent 10. What are multiple reactors? Give example. PART – B (5 x 12 = 60) Answer All the Questions 11. Discuss the integral and differential methods of analysis in finding a suitable rate equation for constant and variable volume reaction systems. (or) 12. At 500 K, the rate of a bimolecular reaction is ten times the rate at 400 K. Find the activation energy of this reaction (a) From Arrhenius Law (b) From Collision theory (c) What is the percentage difference in rate of reaction at 600 K predicted by these two methods? 13. Derive the performance equation (or) design equation for ideal mixed flow reactor and Batch reactor. (or) 14. A liquid phase reaction A R is conducted in plug flow reactor. What size of PFR is needed for 80% conversion of 1000 mole A /hr feed at CAo=1.5mol/l. The rate data are given in table. CA(mol/l) 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 1.0 1.3 2.0 -rA(mol/lmin) 0.1 0.3 0.5 0.6 0.5 0.25 0.1 0.06 0.05 0.045 0.042 15. The elementary liquid phase reaction A B R S is carried out in a plug flow reactor. For equimolar amounts of A and B (CA0 = CB0 = 0.9 mol/L), 94 % conversion is achieved in it. If a CSTR, 10 times as large as the plug flow reactor, were arranged in series with the existing unit, which unit needs to arranged first (in series) to enhance the production rate? (or) 16. Derive an expression for the concentration of reactant in the exit stream from a series of mixed reactors of different sizes and for equal sizes. Assume that the reaction follows first order kinetics and the holding time in the ith reactor is τi. 17. Explain in detail about product distribution for a multiple reaction. (or) 18. Liquid reactant A produces R and S by the following reactions: rR = k1 CA2, k1 = 0.4 m3/ (mol. min) A R, rS = k2 CA k2 = 2(min)-1 AS A feed of aqueous A with CA0 = 40 mol/m3 enters the reactor, reacts to produce R and S, and a mixture of A, R and S leaves. Find CR, CS and τ for 90% conversion of A, in a mixed flow reactor. 19. Explain in detail about general graphical design procedure of a reactor. (or) 20. Discuss the effect of temperature and pressure on equilibrium conversion.